Macroporous-microporous composite Silicalite-1 molecular sieve flake and synthetic method thereof

A molecular sieve and microporous technology, which is used in the field of molecular sieve synthesis to reduce production costs and inhibit growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Mesoporous silica

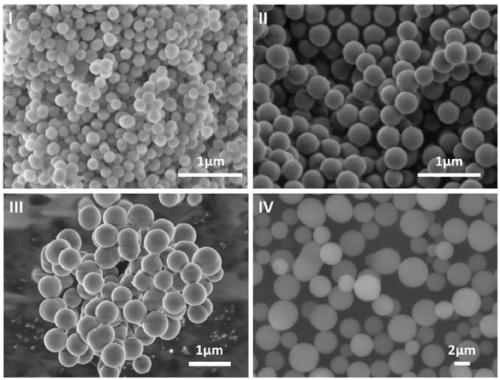

[0039] The morphology and performance parameters of the mesoporous silica used are shown in Table 1, and the scanning electron microscope images are shown in figure 1 .

[0040] Table 1 Morphology and performance parameters of mesoporous silica

[0041]

Embodiment 2

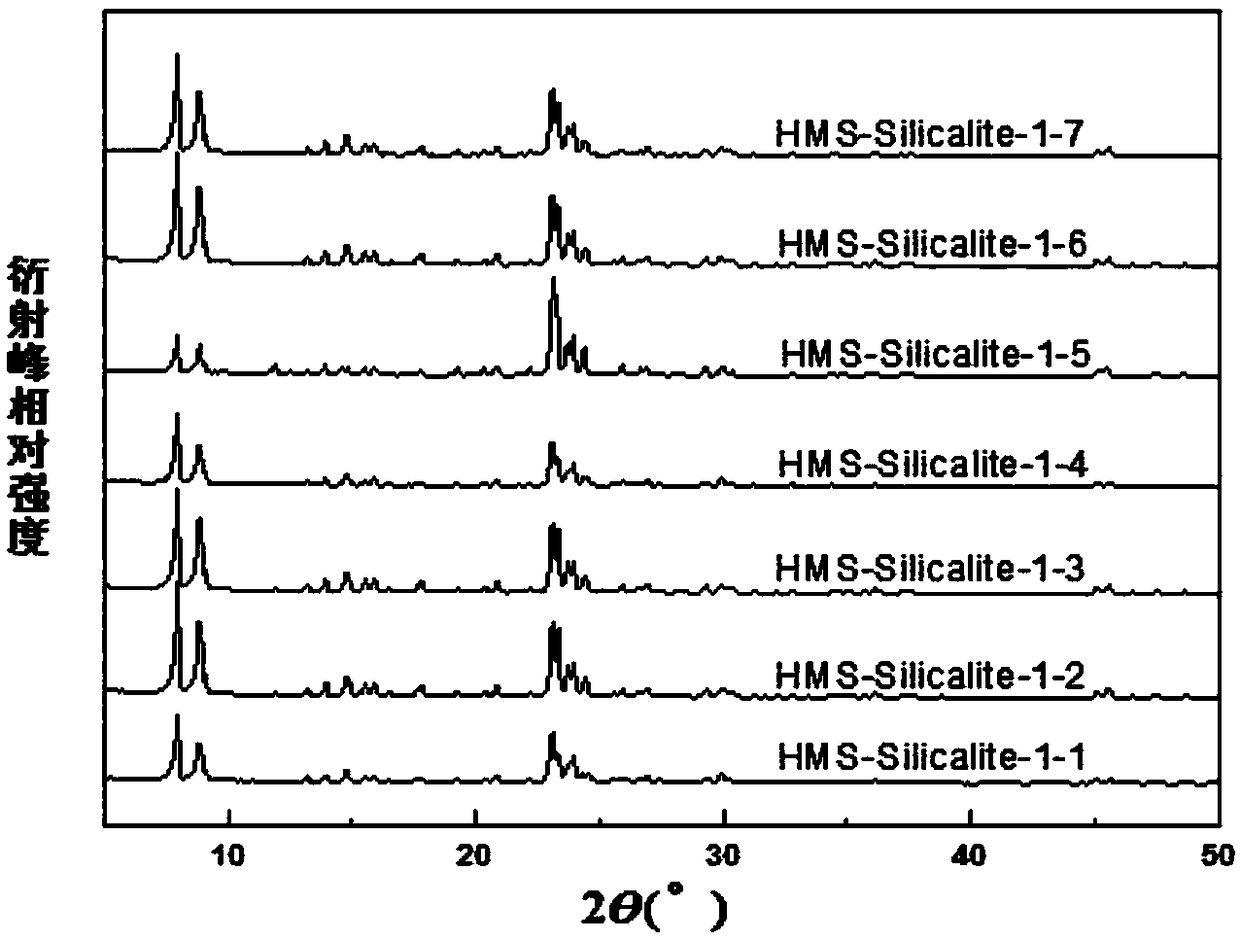

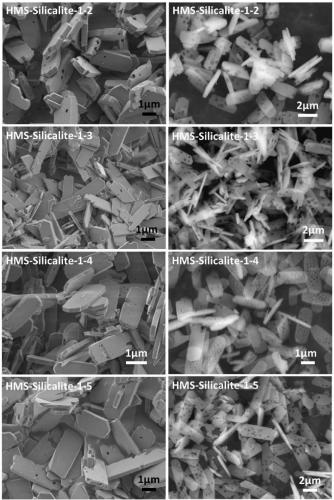

[0042] Example 2: Preparation of sample HMS-Silicalite-1-1-7

[0043] First, add urea and tetrapropylammonium hydroxide into deionized water, stir and dissolve to obtain mixed solution A. An equal volume of the above solution A was impregnated with mesoporous silica, and solid B was obtained after drying at room temperature for a period of time. The above solid mixture B was transferred to the upper plate of the stainless steel autoclave, and water was added to the bottom of the autoclave. Seal the stainless steel reaction kettle, put it in an oven, and crystallize at 100-180°C for 12-50 hours. Cool rapidly after the reaction, separate the solid product, wash with deionized water, dry at 110°C in an air atmosphere and bake at 550°C for 6 hours to obtain a sheet-like macroporous-microporous composite Silicalite-1 molecular sieve. The corresponding relationship between the sample number and the preparation conditions is shown in Table 2.

[0044] The prepared samples were cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com