A kind of medium temperature curing high toughness epoxy resin and preparation method thereof

An epoxy resin, high toughness technology, applied in the field of advanced polymer material science, can solve the problems of being unsuitable for large-scale production, cumbersome steps, strict preparation requirements, etc., to achieve the effect of improving the curing reaction rate and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

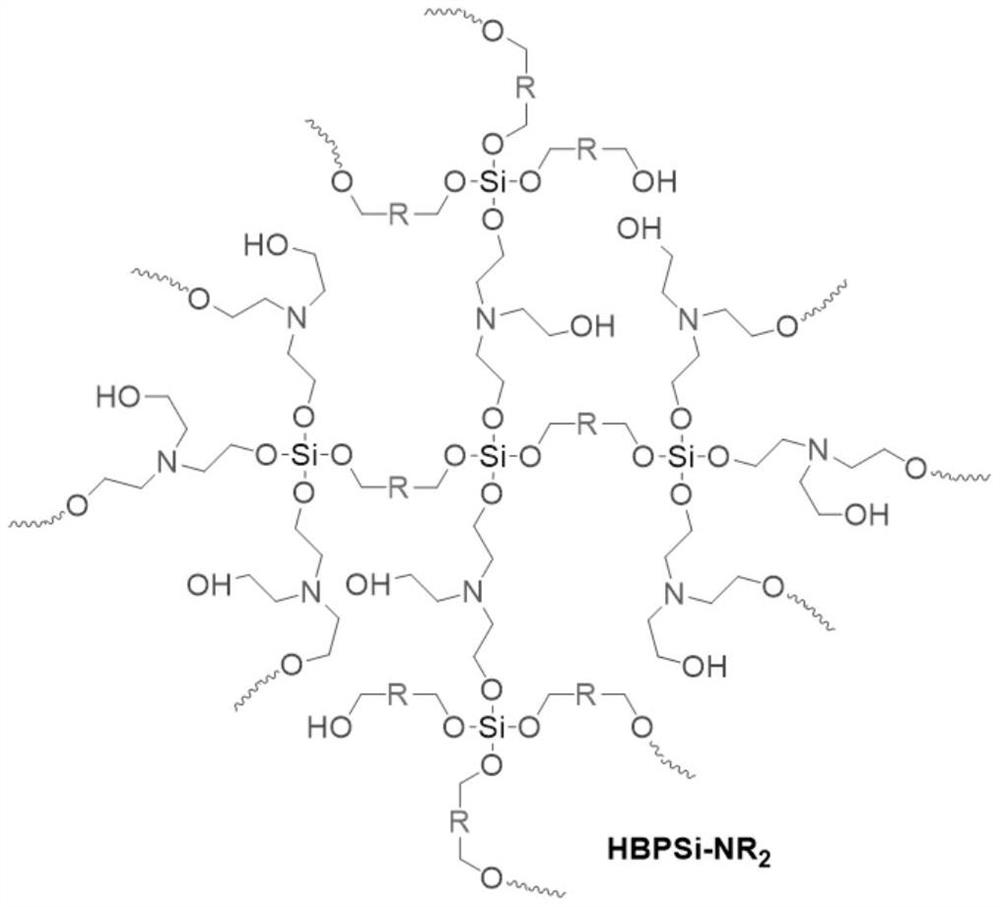

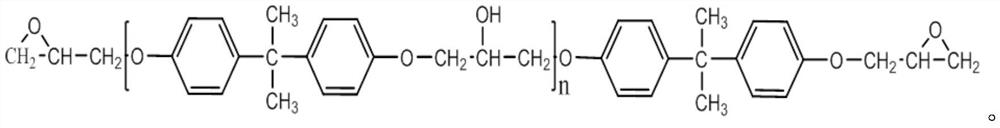

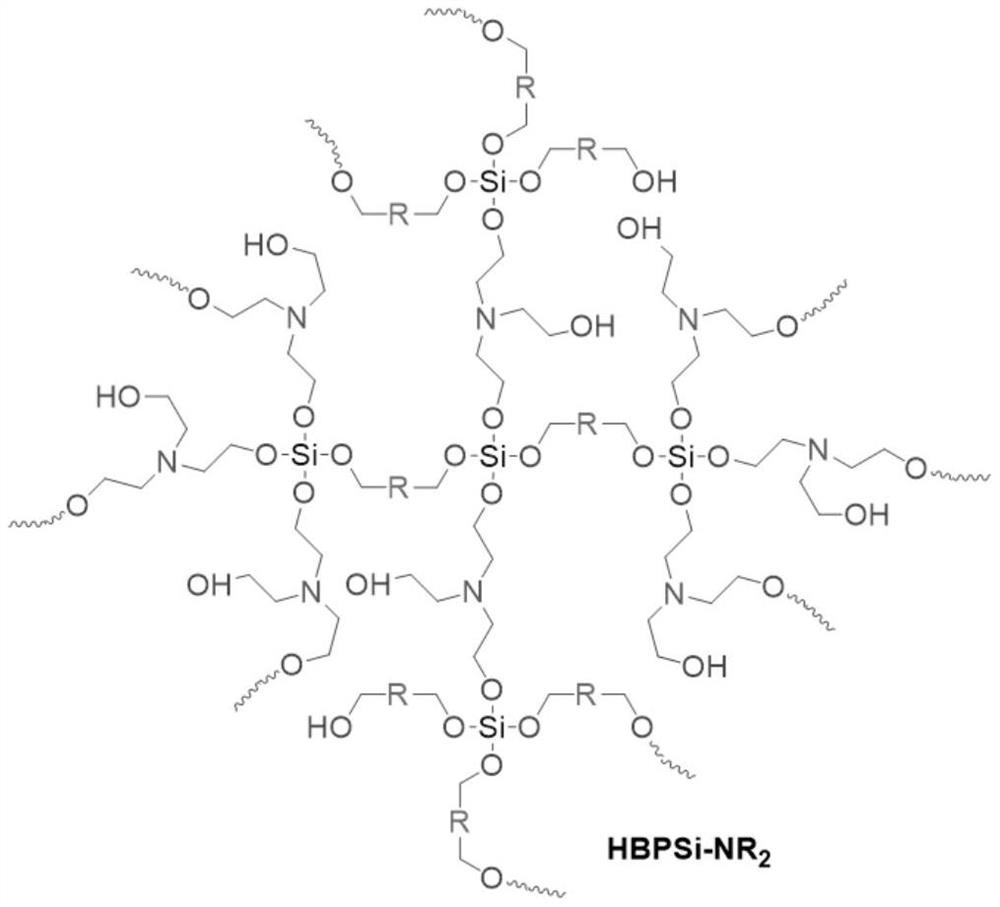

Method used

Image

Examples

Embodiment 1

[0038] Mix 85 parts of bisphenol A epoxy resin and 65 parts of acid anhydride curing agent, and stir at 60°C for 20 minutes to prepare a resin prepolymer. Then, add 15 parts of hyperbranched polysiloxane to the above prepolymer, stir for 10 minutes, pour into a mold that has been preheated at 70°C, and vacuumize to remove air bubbles in a vacuum box at 70°C. Blast drying oven for staged temperature rise curing, the curing process is 80°C / 2h+120°C / 3h, cooling, demoulding, and post-treatment at 150°C for 2h.

Embodiment 2

[0040] Mix 90 parts of bisphenol A epoxy resin and 70 parts of acid anhydride curing agent, and stir at 60°C for 20 minutes to prepare a resin prepolymer. Then, add 10 parts of hyperbranched polysiloxane into the above prepolymer, stir for 10 minutes, pour into a mold that has been preheated at 70°C, and vacuumize to remove air bubbles in a vacuum box at 70°C, and put Blast drying oven for staged temperature rise curing, the curing process is 80°C / 2h+120°C / 3h, cooling, demoulding, and post-treatment at 150°C for 2h.

Embodiment 3

[0042] Mix 95 parts of bisphenol A epoxy resin and 75 parts of anhydride curing agent, stir at 60°C for 20 minutes, and prepare a resin prepolymer. Then, add 5 parts of hyperbranched polysiloxane to the above prepolymer, stir for 10 minutes, pour into a mold that has been preheated at 70°C, and vacuumize to remove air bubbles in a vacuum box at 70°C. Blast drying oven for staged temperature rise curing, the curing process is 80°C / 2h+120°C / 3h, cooling, demoulding, and post-treatment at 150°C for 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com