A catalytic conversion method for increasing production of gasoline and low-carbon olefins

A catalytic conversion method and technology for low-carbon olefins, which are applied in the directions of catalytic cracking, cracking, and processing of hydrocarbon oil, can solve problems such as difficult implementation, low gasoline yield, and complex process, and achieve uniform contact, prolonged reaction time, Strengthen the effect of efficient conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

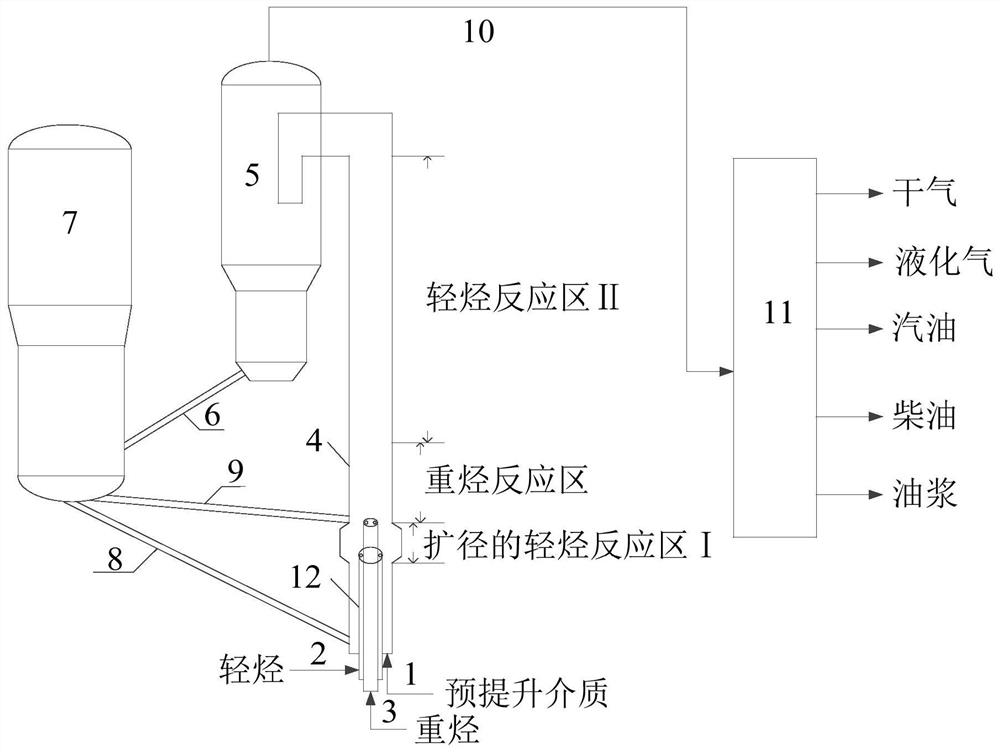

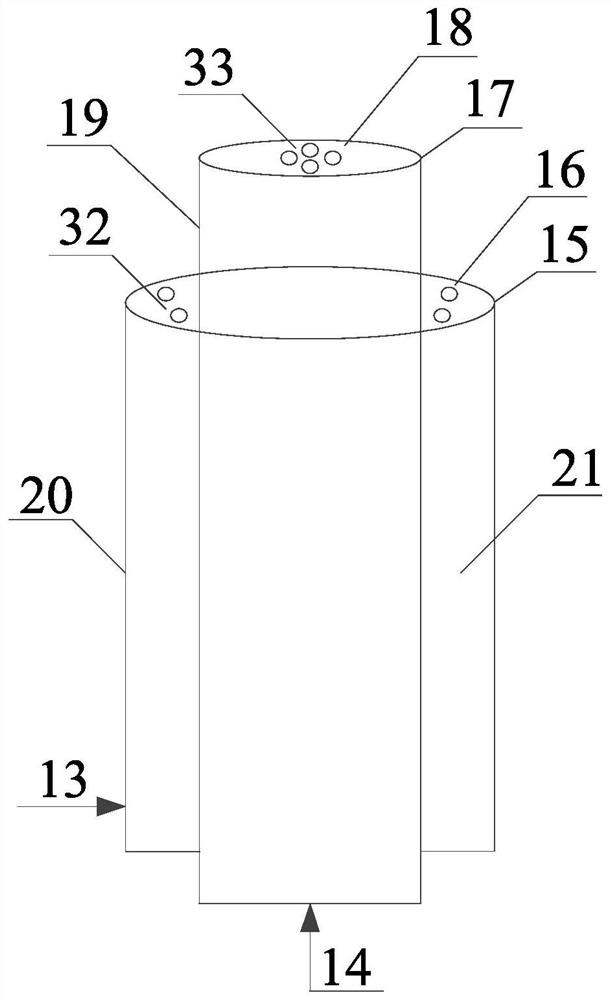

[0047] use figure 1 The device shown and figure 2 The one-piece nozzle shown was tested.

[0048] The heights of the expanded light hydrocarbon reaction zone I, heavy hydrocarbon reaction zone and light hydrocarbon reaction zone II account for 5%, 35% and 55% of the total height of the riser reactor respectively. The ratio of the inner diameter of the riser reactor in the enlarged light hydrocarbon reaction zone I to the inner diameter of the riser reactor in the heavy hydrocarbon reaction zone is 1.5:1. The ratio of the outer diameter of the light hydrocarbon casing 20 of the integrated nozzle 12 to the outer diameter of the heavy hydrocarbon outer casing 19 is 2.20:1, and the diameter of a single light hydrocarbon injection hole on the light hydrocarbon nozzle 16 is the same as that of the single heavy hydrocarbon nozzle 18 on the heavy hydrocarbon outer nozzle. The aperture ratio of the hydrocarbon outer injection holes is 1.429:1. The pre-lift medium was nitrogen.

[...

Embodiment 2

[0056] use figure 1 The device shown and figure 2 The one-piece nozzle shown was tested.

[0057] The heights of the expanded light hydrocarbon reaction zone I, heavy hydrocarbon reaction zone and light hydrocarbon reaction zone II account for 5%, 35% and 55% of the total height of the riser reactor respectively. The ratio of the inner diameter of the riser reactor in the enlarged light hydrocarbon reaction zone I to the inner diameter of the riser reactor in the heavy hydrocarbon reaction zone is 1.5:1. The ratio of the outer diameter of the light hydrocarbon casing 20 of the integrated nozzle 12 to the outer diameter of the heavy hydrocarbon outer casing 19 is 2.20:1, and the diameter of a single light hydrocarbon injection hole on the light hydrocarbon nozzle 16 is the same as that of the single heavy hydrocarbon nozzle 18 on the heavy hydrocarbon outer nozzle. The aperture ratio of the hydrocarbon outer injection holes is 1.429:1. The pre-lift medium was nitrogen.

[...

Embodiment 3

[0066] use figure 1 The device shown and figure 2 The one-piece nozzle shown was tested.

[0067] The heights of the expanded light hydrocarbon reaction zone I, heavy hydrocarbon reaction zone and light hydrocarbon reaction zone II account for 5%, 35% and 55% of the total height of the riser reactor respectively. The ratio of the inner diameter of the riser reactor in the enlarged light hydrocarbon reaction zone I to the inner diameter of the riser reactor in the heavy hydrocarbon reaction zone is 1.5:1. The ratio of the outer diameter of the light hydrocarbon casing 20 of the integrated nozzle 12 to the outer diameter of the heavy hydrocarbon outer casing 19 is 2.20:1, and the diameter of a single light hydrocarbon injection hole on the light hydrocarbon nozzle 16 is the same as that of the single heavy hydrocarbon nozzle 18 on the heavy hydrocarbon outer nozzle. The aperture ratio of the hydrocarbon outer injection holes is 1.429:1. The pre-lift medium was nitrogen.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com