Preparation method of wet-white leather

A technology for wet white leather and bare leather, applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, tanning treatment, etc. The surface dehydration is fast, the shrinkage is too fast and other problems, and the physical and mechanical properties are good, the porosity is maintained, and the environmental pollution is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

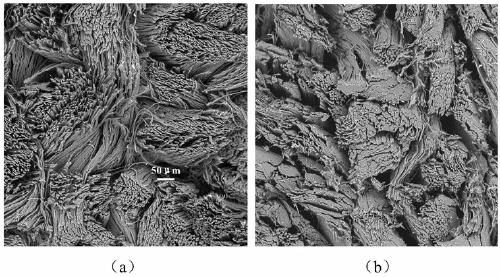

Image

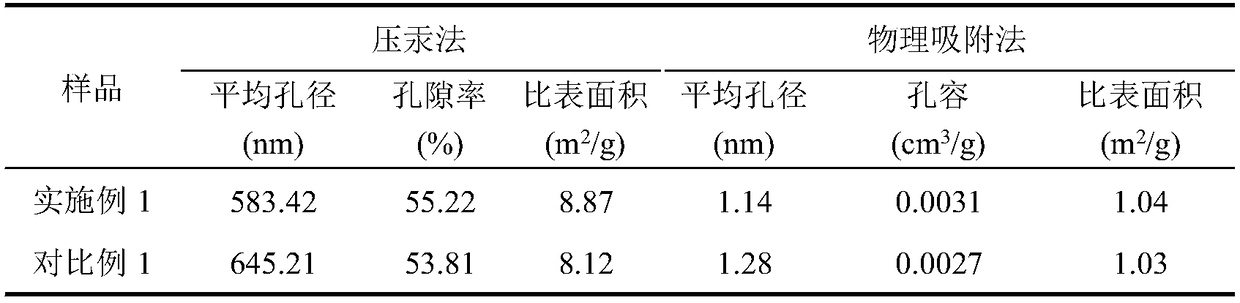

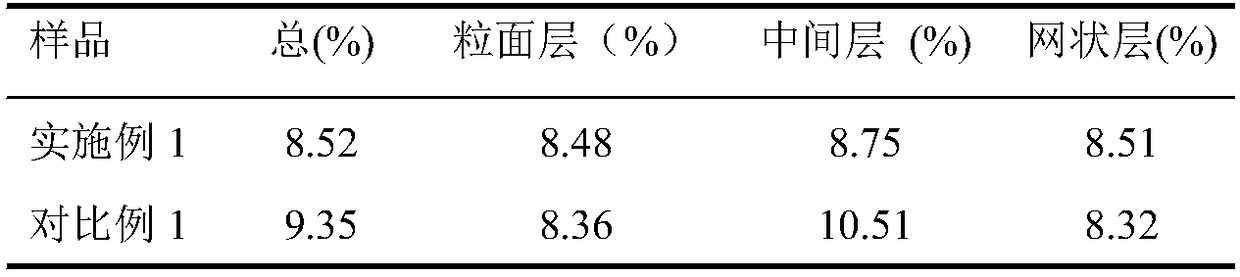

Examples

Embodiment 1

[0029] (1) Adjust the pH of the softened skin to about 6.9, and squeeze the water; through the water squeezing process, the total amount of dehydration in the subsequent dehydration process is reduced, and the dehydration efficiency is improved;

[0030](2) Put the above-mentioned squeezed skin into the rotatable sealing device, add absolute ethanol with a tare weight of 400%, recover the bath liquid after rotating for 120 minutes, and then add ethanol for the second dehydration; rotate the device to make the skin bend , Produce a beating effect, which is conducive to the penetration of materials and speed up the dehydration process; according to the water content in the skin, in the second stage of dehydration, the amount of dehydration can be increased by increasing the amount of solution, and the dehydration speed can be accelerated;

[0031] (3) Configure the mixed solution of acetone and absolute ethanol, the ratio of acetone and ethanol is 1:1, add the mixed solution with...

Embodiment 2

[0042] (1) Adjust the pH of the softened skin to about 6.9, and squeeze the water;

[0043] (2) Add the above-mentioned squeezed skin into the rotatable sealing device, add absolute ethanol with a tare weight of 200%, recover the bath liquid after rotating for 240 minutes, and then add ethanol for the second, third and fourth dehydration;

[0044] (3) Configure the mixed solution of acetone and isopropanol, the ratio of acetone and isopropanol is 1:2, add the mixed solution with a tare weight of 200%, and recover the bath solution after rotating for 600min;

[0045] (4) Add acetone with a tare weight of 200%, take it out after rotating for 240 minutes, and obtain wet white skin.

Embodiment 3

[0047] (1) Adjust the pH of the pickled skin to about 5.4, and squeeze the water;

[0048] (2) Add the above-mentioned squeezed skin into the rotatable sealing device, add absolute ethanol with a tare weight of 400%, recover the bath liquid after rotating for 60 minutes, and then add ethanol for the second dehydration;

[0049] (3) Configure the mixed solution of acetone and absolute ethanol, the ratio of acetone and ethanol is 1:1, add the mixed solution with a tare weight of 400%, and recycle the bath solution after rotating for 60 minutes;

[0050] (4) Add acetone with a tare weight of 400%, take it out after rotating for 60 minutes, and obtain wet white skin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com