Preparation method of flavored kelp

A technology of kelp and flavor, applied in the direction of bacteria and food ingredients used in food preparation as odor improvers, food ingredients containing yeast, etc., can solve the problems of the taste of kelp deep-processing products, hinder the development of kelp industry, etc., and achieve enhanced crispness , improve efficiency, strong fragrance and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

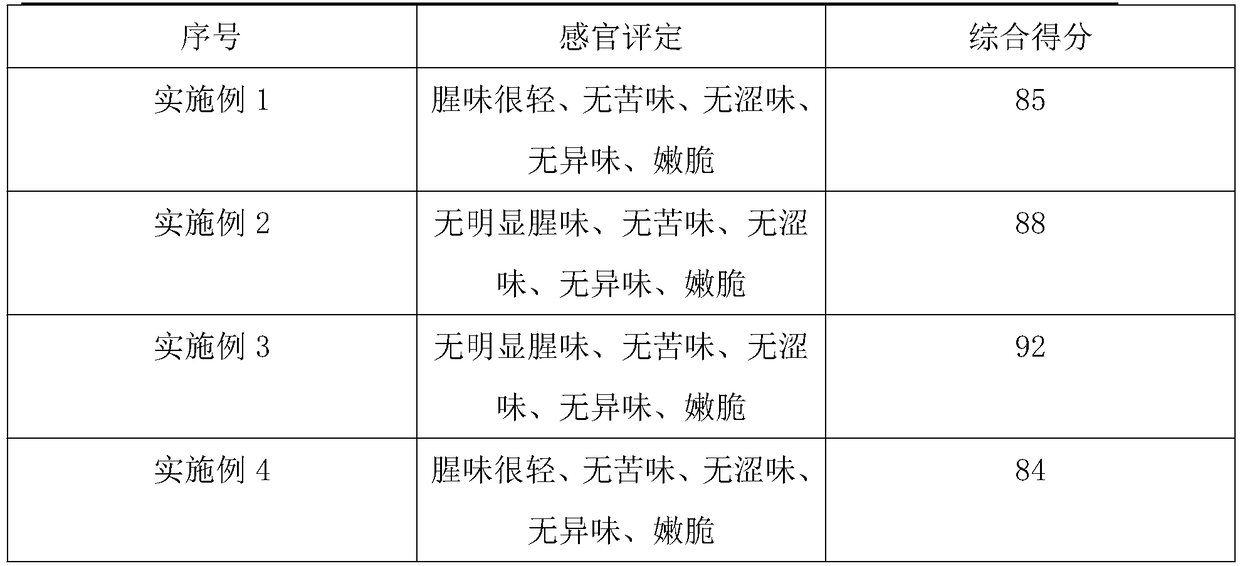

Embodiment 1

[0046] A preparation method of flavor kelp, comprising the following:

[0047] (1) Pretreatment: After cleaning and cutting fresh seafood, soak them in an aqueous solution with a mass concentration of 4.5% sodium carbonate for 4 hours, then rinse with clean water and drain for later use;

[0048] (2) Deodorization: the kelp prepared in step (1) is sterilized at 90°C for 40 minutes and mixed with yeast liquid at a mass ratio of 1:4, and then 1-2% of the dry matter of kelp is added to activate the yeast liquid, fermented at 32°C for 1 hour in a sealed state;

[0049](3) Ripening: ripen the kelp prepared in step (2), then add 2% sea-tangle seasoning raw material while hot and mix it in a tank for airtight treatment for 30 minutes; if the temperature drops too fast, the tank can be placed In the water bath, the temperature is controlled above 50°C; the aging method can be adopted in the existing conventional aging method, such as steaming, oil frying, etc.;

[0050] (4) Mixing: ...

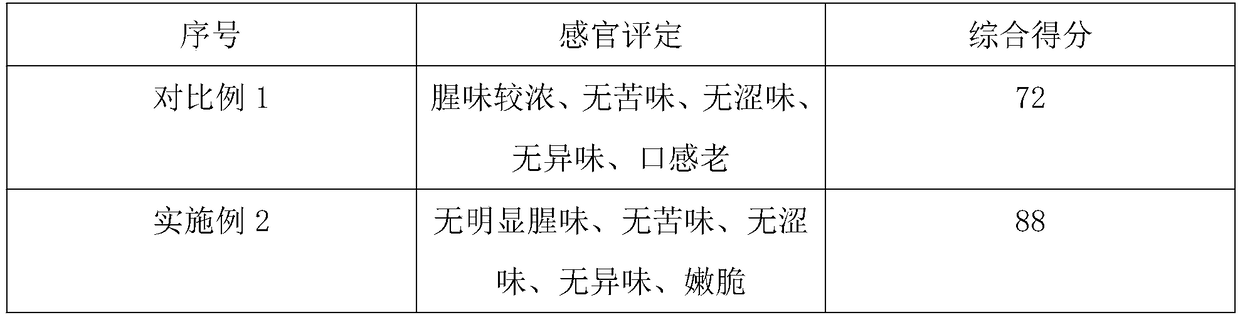

Embodiment 2

[0052] A preparation method of flavor kelp, comprising the following:

[0053] (1) Pretreatment: After cleaning and cutting fresh seafood, place them in an aqueous solution with a mass concentration of 5% sodium carbonate and soak them for 6 hours, then rinse them with clean water and drain them for later use;

[0054] (2) Deodorization: the kelp prepared in step (1) is sterilized at 120°C for 10 minutes and mixed with yeast liquid at a mass ratio of 1:5, and then 3-4% of the dry matter of kelp is added to activate the yeast liquid, fermented at 33°C for 3 hours in a sealed state;

[0055] (3) Ripening: ripen the kelp prepared in step (2), then add 3-4% of the sea-tangle’s quality seasoning raw material while hot and mix it in a tank for 50 minutes; if the temperature drops too fast, the tank can be Placed in a water bath, the temperature is controlled above 50°C; the aging method can be adopted in the existing conventional aging methods, such as steaming, oil frying, etc.; ...

Embodiment 3

[0058] A preparation method of flavor kelp, comprising the following:

[0059] (1) Pretreatment: After cleaning and cutting fresh seafood, soak them in an aqueous solution with a mass concentration of 6% sodium bicarbonate for 9 hours, then rinse them with clean water and drain them for later use;

[0060] (2) Deodorization: Sterilize the kelp prepared in step (1) at 90°C for 40 minutes and mix it with yeast liquid at a mass ratio of 1:6, then add 7-8% lactic acid bacteria activation solution of kelp dry matter , fermented at 33°C for 3 hours in a sealed state;

[0061] (3) Ripening: ripen the kelp prepared in step (2), then add seasoning raw material with 4% of the mass of kelp and mix it while hot and put it in a tank for airtight treatment for 60 minutes; if the temperature drops too fast, the tank can be placed In the water bath, the temperature is controlled above 50°C; the aging method can be adopted in the existing conventional aging method, such as steaming, oil fryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com