Board batch modular lateral extrusion forming device and method

An extrusion forming and modular technology, applied in the field of extrusion forming, can solve the problems of difficult quality control, long process flow, poor process flexibility, etc., to achieve easy replacement and recycling, comprehensive mechanical properties improvement, and material utilization rate improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

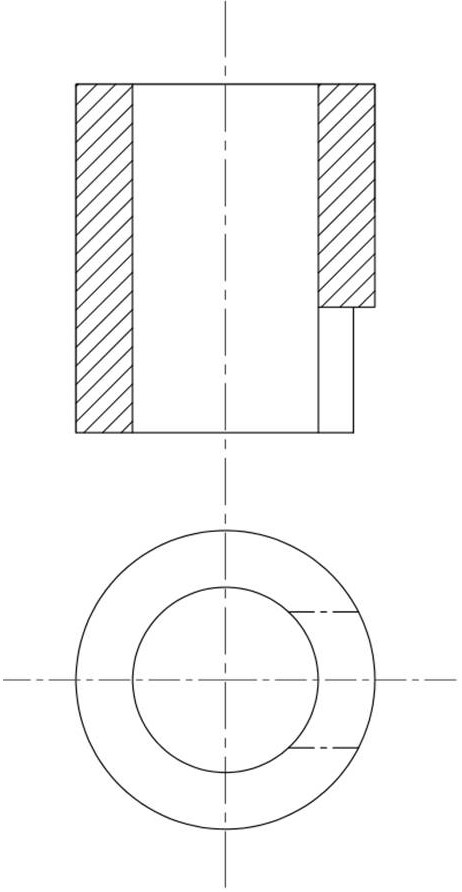

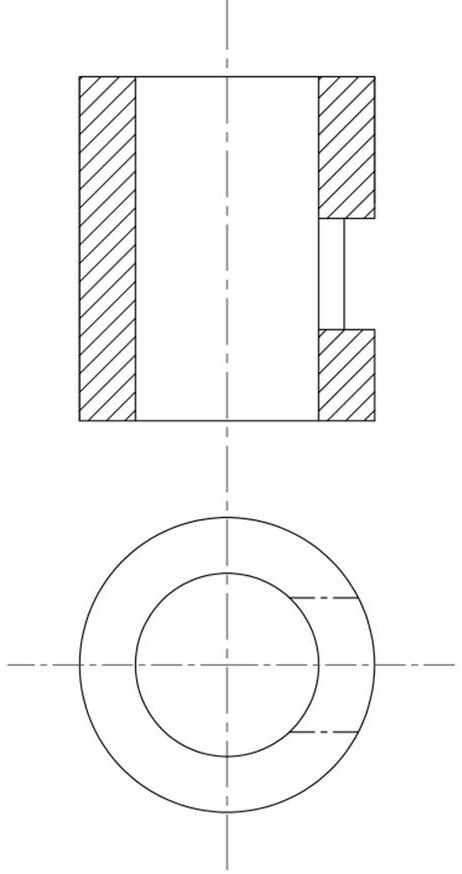

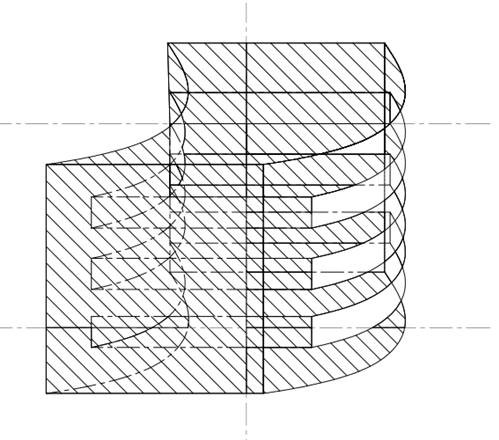

[0039] Specific implementation mode one: combine Figure 1~3 , Figure 7~9 This embodiment will be described. The device of this embodiment includes a punch 1 , a blank 2 , a base 3 , an insert 4 , an inner sleeve 5 , and an outer sleeve 6 . The base 3 is placed on the press table, the inner sleeve 5 is placed on the base 3, the insert 4 is put into the groove 5-1 on the side of the inner sleeve 5, and the outer sleeve 6 is placed on the base 3, The outside of the combination of the insert 4 and the inner sleeve 5 .

specific Embodiment approach 2

[0040] Specific implementation mode two: combination figure 1 , figure 2 , Figure 4 , Figure 7 , Figure 8 and Figure 10 Describe this embodiment. This embodiment is to form plates with different thicknesses in a single pass. The shape of the formed plate can be controlled by replacing the insert 4 and changing the slot hole 4-1. The specific forming dimensions are based on the specifications of the plate in actual production. And the size of the module is adjusted, the height of each slot hole 4-1 is different, in the same time, the length of the plate formed by the higher cavity is shorter, and the formed part is Figure 10 , and other connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0041] Specific implementation mode three: combination figure 1 , figure 2 , Figure 5 , Figure 7 , Figure 8 and Figure 11 Describe this embodiment. This embodiment is to form a plate with any curvature. Start the press to load and shape the punch 1, and the compressed deformed blank 2 flows into the cavity between the ribs 7 in the insert 4 in the radial direction, and the formed part As shown in Figure 11, the metal is in a flowing state during the forming process, and the formed part does not have a rebound phenomenon, which significantly improves the shapeability, and other connection relationships are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com