Omnidirectional lithium battery pack industrial welding robot

A welding robot, lithium battery pack technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting the welding effect, low welding quality, serious oxidation on the surface of the pole piece, etc., to increase welding The effect of quality and welding efficiency, practicality, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

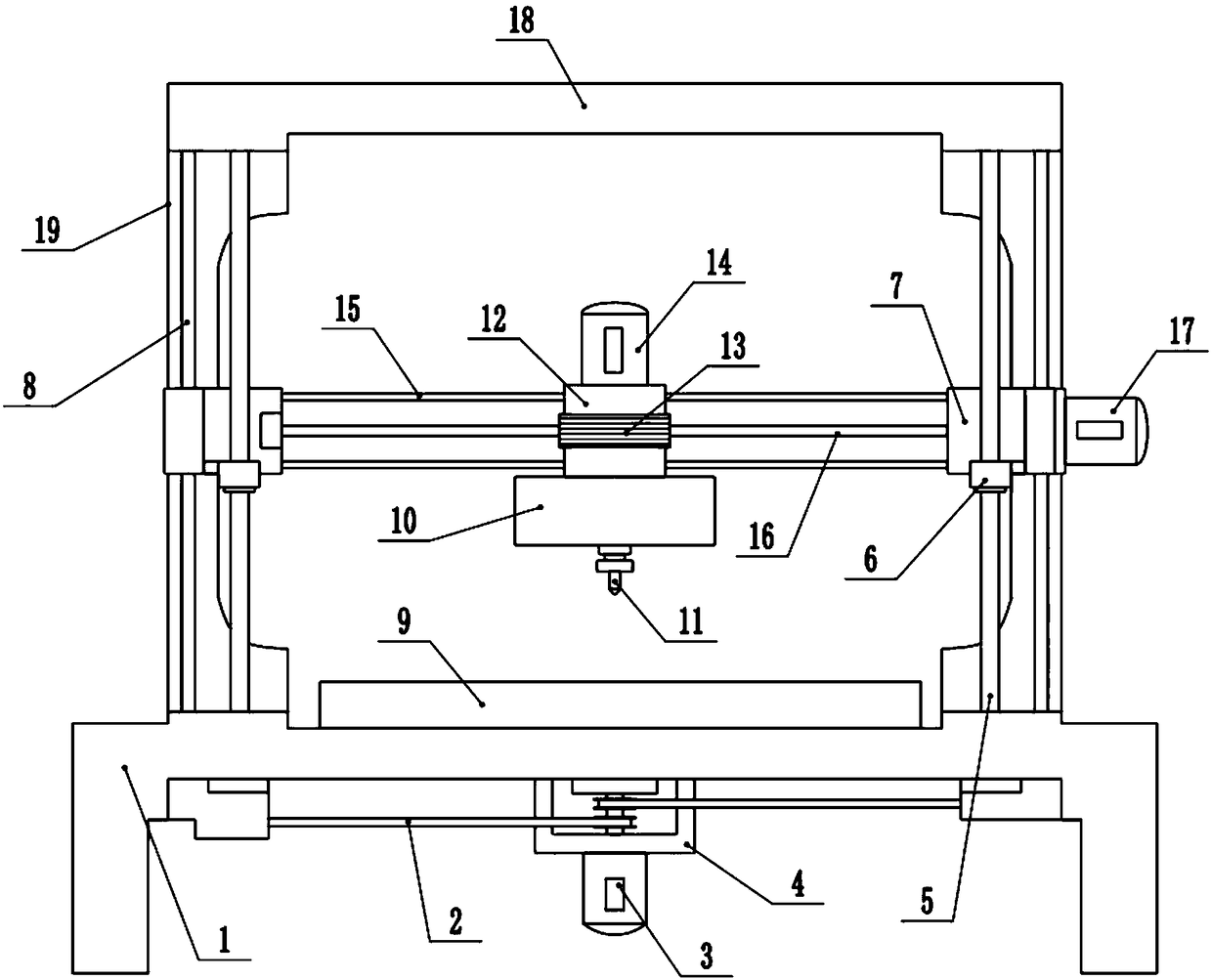

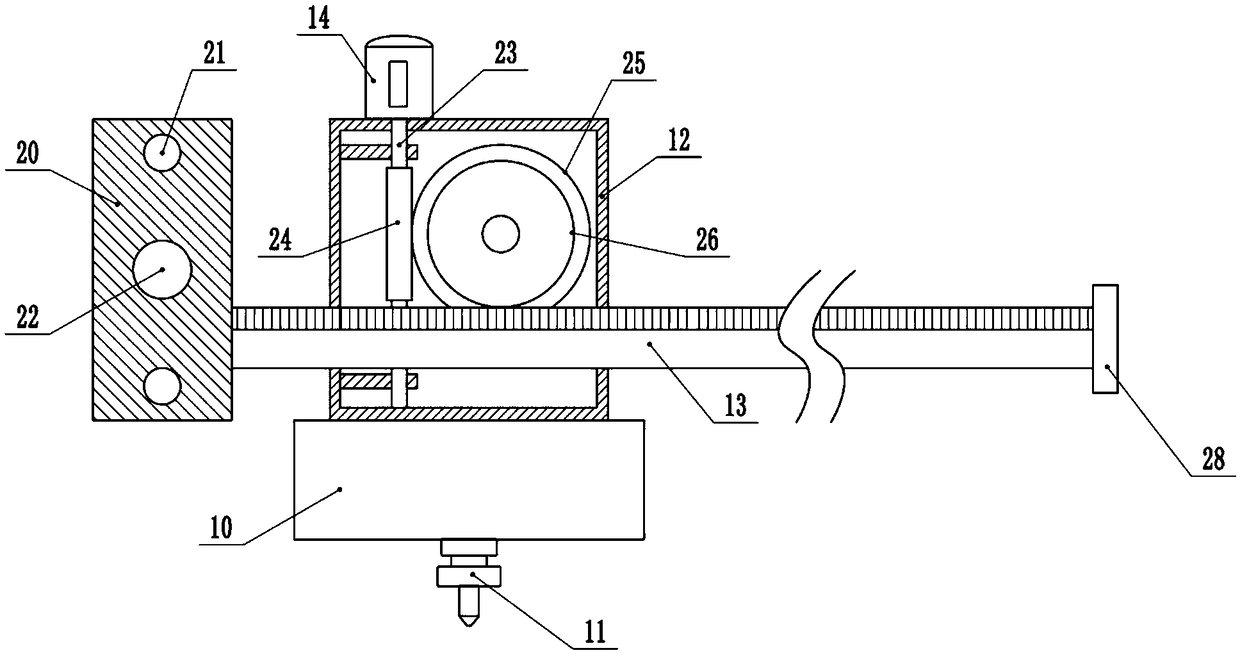

[0028] refer to figure 1 , in the embodiment of the present invention, an all-round industrial welding robot for lithium battery packs, including a welding base 1, the welding base 1 is an inverted U-shaped structure, thereby ensuring the support and fixation of the entire device and the ground, the upper end of the welding base 1 Support frame 19 is installed on both sides, top frame 18 is installed on the top of support frame 19, motor frame 4 is installed in the middle part of the lower end of described welding base 1, is used to realize the installation and fixation with vertical motor 3, and vertical motor frame 4 lower end is installed with Straight motor 3, the output shaft of vertical motor 3 is connected with vertical screw mandrel 5 through belt transmission mechanism 2, and described belt transmission mechanism 2 comprises two driving pulleys, and two driving pulleys are respectively connected with driven belt by belt The driven pulley is respectively fixed on the b...

Embodiment 2

[0032] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a limit stopper 28 is installed in the middle of the front end of the fixed rack 13, and a limit stopper 28 is arranged at the front end of the fixed rack 13 , can make the forward and backward moving box 12 not exceed the front end position when the fixed rack 13 moves, ensuring the reliability of the device.

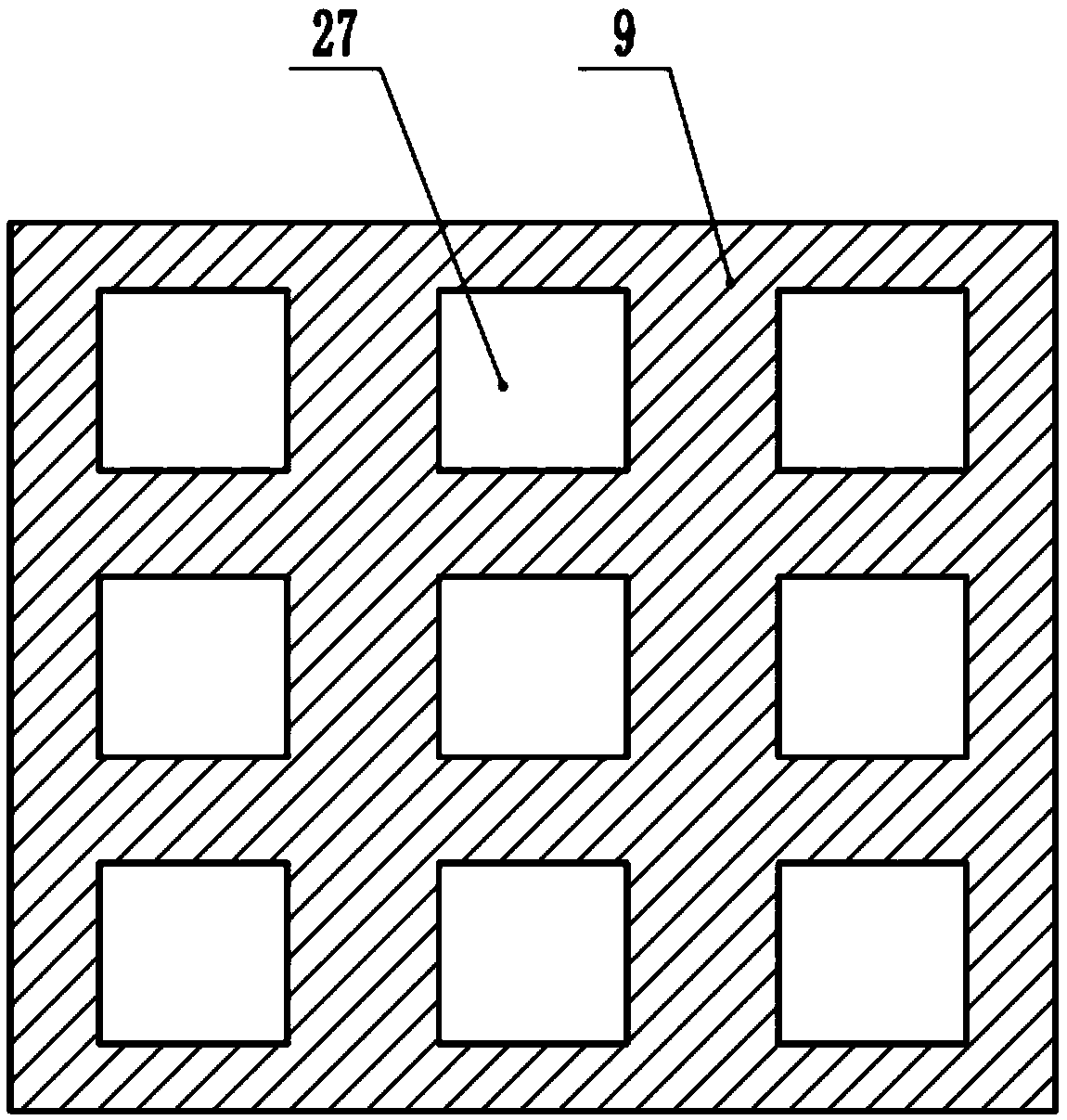

[0033] In the present invention, when working, a plurality of lithium batteries are placed in the placement groove 27 on the placement platform 9, and then by starting the vertical motor 3, the horizontal motor 17 and the front and rear motors 14, the relative position of the welding head 11 on the placement platform 9 is The position can be changed, so that the electrode of any lithium battery on the placement table 9 can be accurately welded without moving the lithium battery, so as to realize all-round welding of the lithium battery. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com