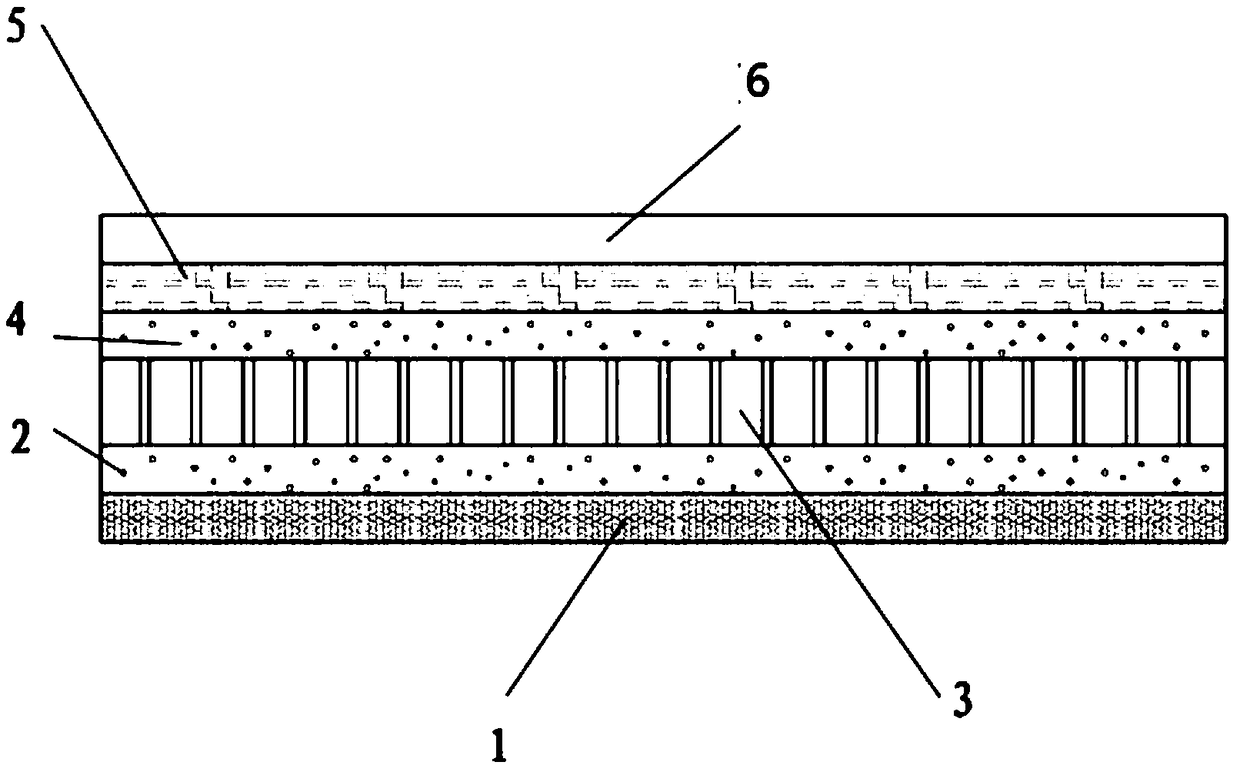

Novel breathable deodorizing antibacterial cushion

An antibacterial pad, a new type of technology, applied in the direction of fiber chemical characteristics, conjugated synthetic polymer artificial filament, layered products, etc., can solve the problems of a large number of bacteria, poor air permeability and heat dissipation performance, poor air permeability, etc. , to achieve good biocompatibility, improve air permeability, and inhibit the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: core material: 48 parts of antibacterial anion powders, 35 parts of emulsifiers; Wall material: 40 parts of urea-formaldehyde resins. The antibacterial anion powder includes the following components in parts by weight: 3 parts of nano-scale titanium dioxide, 16 parts of diatomaceous earth, 10 parts of tourmaline powder, and 5 parts of bamboo charcoal powder.

[0033] Described anion microcapsules are prepared in the following manner:

[0034] 1) The urea-formaldehyde resin is synthesized by urea and formaldehyde in a molar ratio of 1:2; mix the urea and formaldehyde solution, stir and dissolve, adjust the pH to 8, and react at 65 degrees for 1 hour to obtain a transparent and viscous urea-formaldehyde resin prepolymerization body;

[0035] 2) Synthesis of capsule core emulsion: add antibacterial negative ion powder to the aqueous solution of emulsifier sodium dodecylbenzenesulfonate, heat to 45°C and stir, and use a high-shear dispersing emulsifier at 500...

Embodiment 2

[0042] Embodiment 2: core material: 45 parts of antibacterial anion powders, 25 parts of emulsifiers; Wall material: 35 parts of urea-formaldehyde resins.

[0043] The antibacterial anion powder includes the following components in parts by weight: 3 parts of nano-scale titanium dioxide, 16 parts of diatomaceous earth, 10 parts of tourmaline powder, and 5 parts of bamboo charcoal powder.

[0044] Described anion microcapsules are prepared in the following manner:

[0045]1) The urea-formaldehyde resin is synthesized by urea and formaldehyde in a molar ratio of 1:2; mix the urea and formaldehyde solution, stir and dissolve, adjust the pH to 8, and react at 65 degrees for 1 hour to obtain a transparent and viscous urea-formaldehyde resin prepolymerization body;

[0046] 2) Synthesis of capsule core emulsion: add antibacterial negative ion powder into emulsifier polyvinyl alcohol aqueous solution, heat to 45°C and stir, and emulsify with a high-shear dispersing emulsifier at a s...

Embodiment 3

[0052] Embodiment 3: core material: 50 parts of antibacterial anion powders, 50 parts of emulsifiers; Wall material: 45 parts of urea-formaldehyde resins.

[0053] The antibacterial anion powder includes the following components in parts by weight: 3 parts of nano-scale titanium dioxide, 16 parts of diatomaceous earth, 10 parts of tourmaline powder, and 5 parts of bamboo charcoal powder.

[0054] Described anion microcapsules are prepared in the following manner:

[0055] 1) The urea-formaldehyde resin is synthesized by urea and formaldehyde in a molar ratio of 1:2; mix the urea and formaldehyde solution, stir and dissolve, adjust the pH to 8, and react at 65 degrees for 1 hour to obtain a transparent and viscous urea-formaldehyde resin prepolymerization body;

[0056] 2) Synthesis of capsule core emulsion: add antibacterial anion powder into emulsifier aqueous solution, heat to 45°C and stir, and emulsify with a high-shear dispersing emulsifier at a speed of 5000-15000r / min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com