Method and reaction device for removal of total nitrogen from black and foul water by iron-carbon micro-electrolysis combined with natural zeolite in series

A technology of iron-carbon micro-electrolysis and natural zeolite, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as effluent does not meet discharge standards, increase treatment costs, and harsh conditions, and achieve high efficiency Application value, no excess sludge discharge, and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

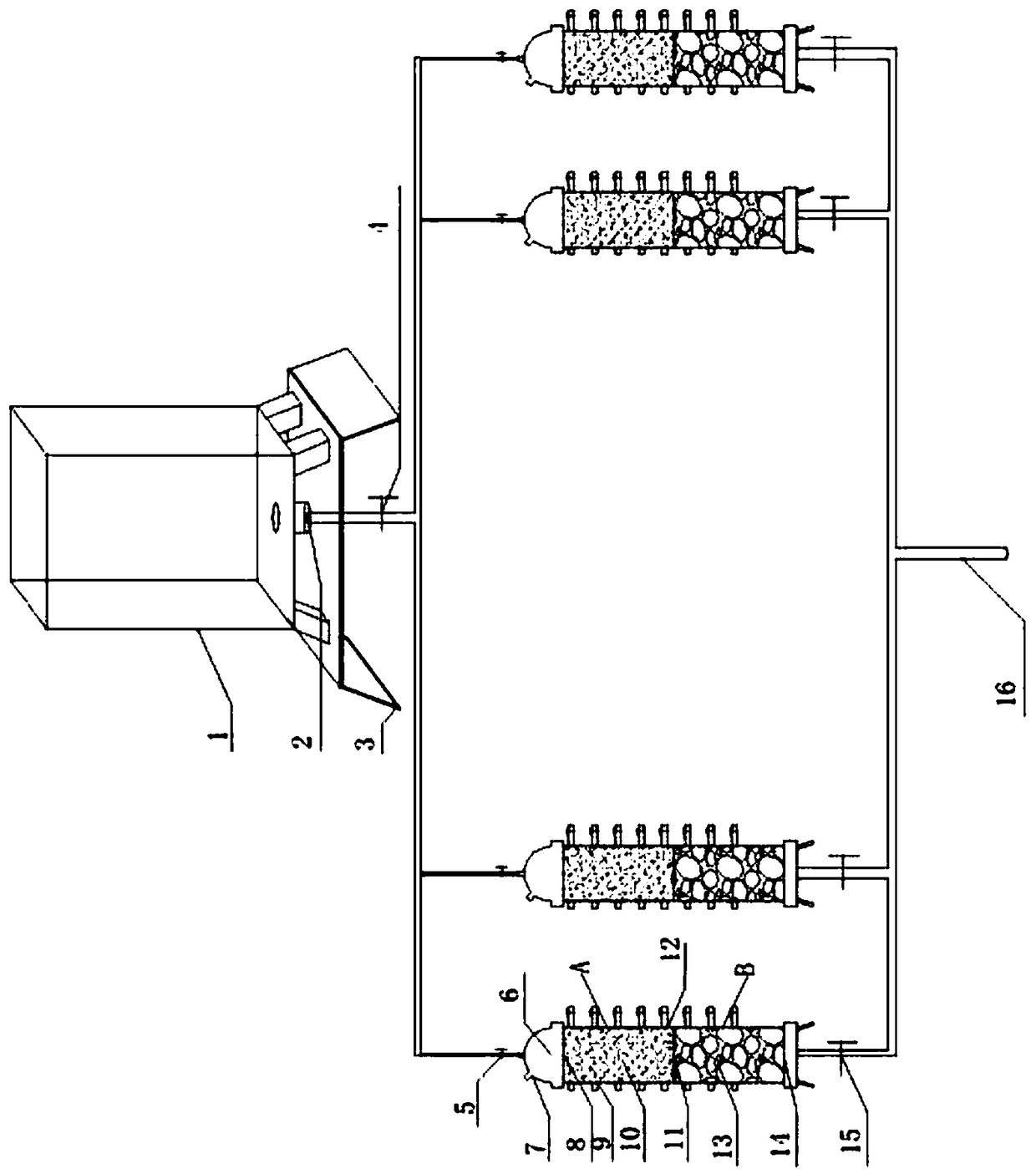

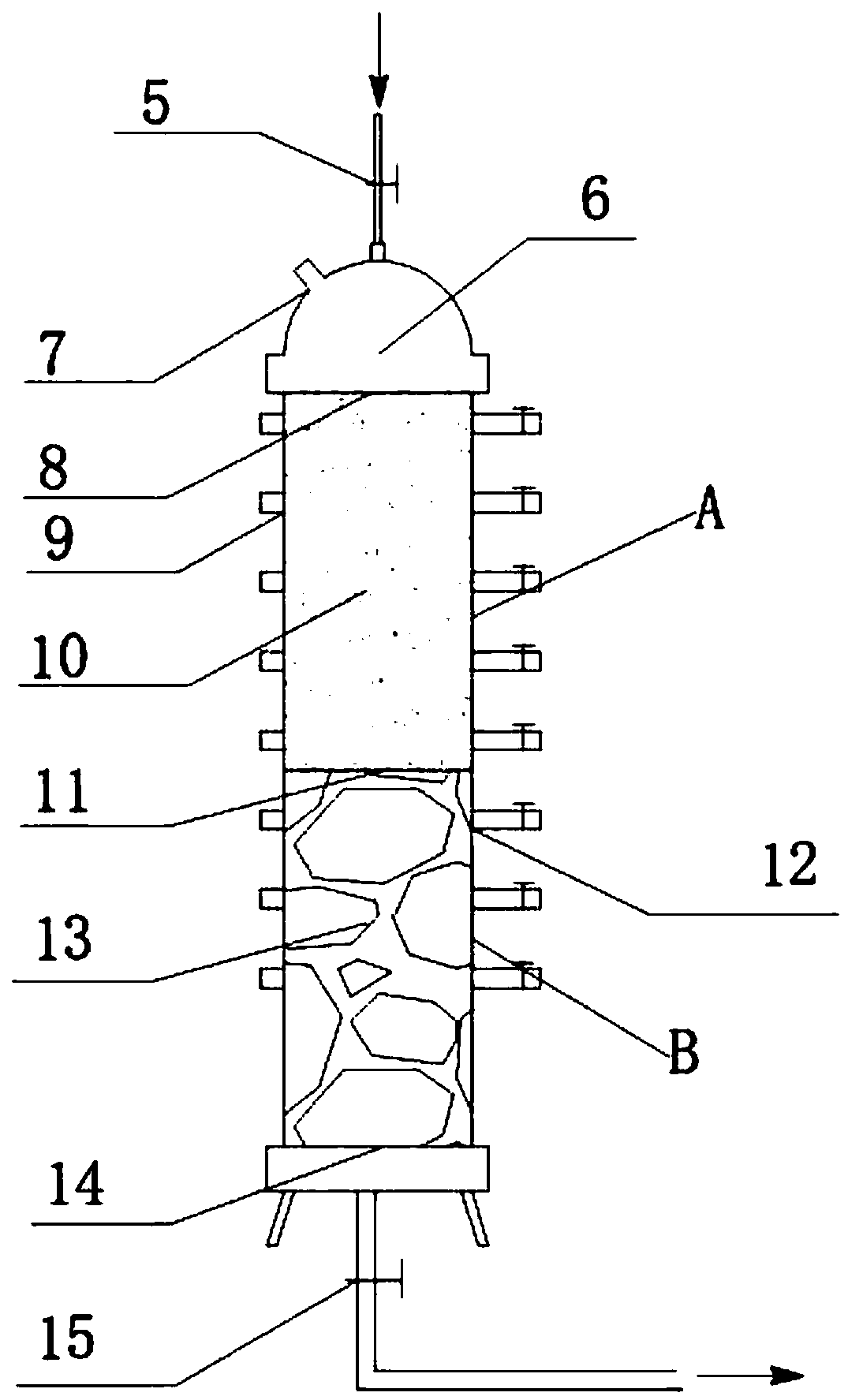

[0027] The method of the present invention is: reaction column comprises Fe-C micro-electrolysis reaction column and natural zeolite reaction column, Fe-C micro-electrolysis reaction column and natural zeolite reaction column are communicated together, and Fe-C micro-electrolysis reaction column is on top, natural The zeolite reaction column is at the bottom, the upper part of the reaction column is connected to the water tank, and the lower end of the reaction column is connected to the outlet pipe. The water tank contains black and odorous water. The black and odorous water passes through the Fe-C micro-electrolysis reaction column through gravity. Electron transfer reduces nitrate nitrogen and nitrite nitrogen to ammonia nitrogen; ferrous ions will appear in the effluent of the Fe-C micro-electrolysis reaction column; when the effluent flows through the natural zeolite reaction column, the residual ferrous ions in the water and the The ammonia nitrogen will exchange ion with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com