A kind of preparation method of phenolic hydroxyl self-polymerization hydrogel

A phenolic hydroxyl and self-polymerization technology is applied in the field of preparation of phenolic hydroxyl self-polymerized hydrogel, which can solve the problems of complex conditions, difficult double bond polymerization, and difficult double bond hydrogel polymerization, and achieves good biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

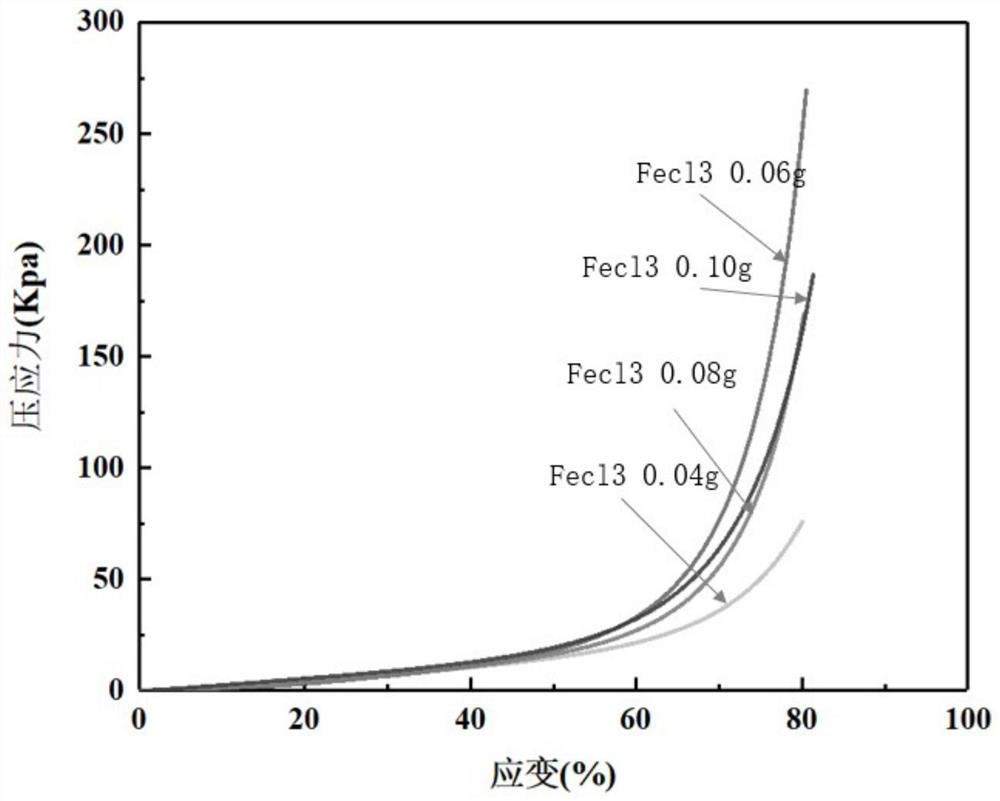

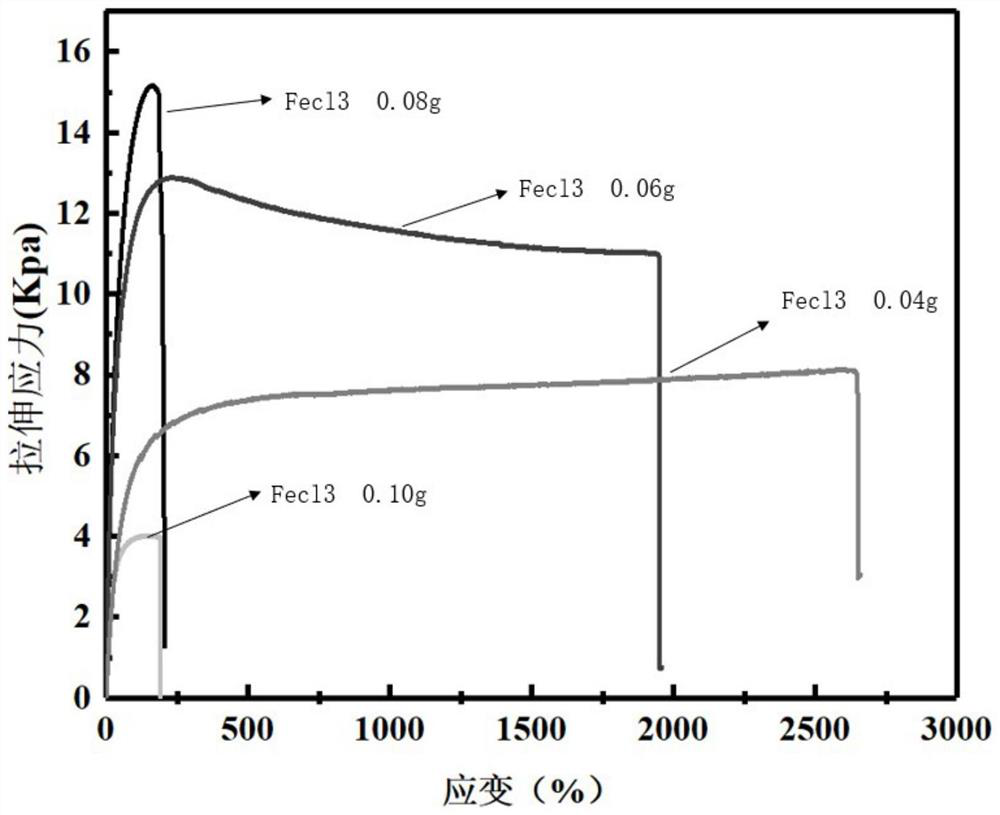

[0032] Add 0.003g of dopamine to 10ml of aqueous solution containing 0.06g of ferric chloride hexahydrate, stir evenly, and let it stand for 10s; add 2.7ml of acrylic acid, stir evenly, add 0.015g of ammonium persulfate, stir evenly, and let stand to form a gel.

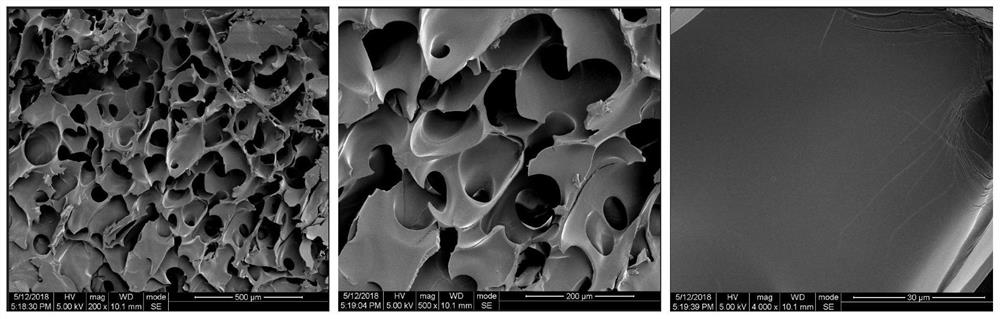

[0033] Its hydrogel structure is as image 3 As shown, it can be seen from the figure that the hydrogel has a uniform porous structure inside, a smooth sheet structure, and a good distribution of internal crosslinks.

Embodiment 2

[0035] Add 0.003g of dopamine to 10ml of aqueous solution containing 0.10g of ferric chloride hexahydrate, stir evenly, and let stand for 10s; add 2.7ml of acrylic acid, stir evenly, add 0.015g of ammonium persulfate, stir evenly, and then stand still to form a gel.

Embodiment 3

[0037] Add 0.003g of dopamine to 10ml of aqueous solution containing 0.08g of ferric chloride hexahydrate, stir evenly, and let stand for 10s; add 2.7ml of acrylic acid, stir evenly, add 0.015g of ammonium persulfate, stir evenly, and let stand to form a gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com