Octavinyl-POSS and ethylene glycol dimethacrylate co-crosslinked boron affinity monolithic column and preparation method thereof

A technology of ethylene glycol dimethacrylate and octavinyl, which is applied in the field of boron affinity monolithic column and its preparation, can solve the problems of lack of specificity in separation effect, and achieve easy operation, good permeability and recovery rate Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

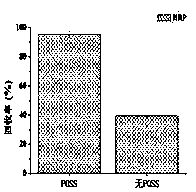

[0028] Comparison of solid-phase microextraction recoveries of octavinyl-POSS and ethylene glycol dimethacrylate co-crosslinked monolithic columns with monolithic columns without octavinyl-POSS crosslinking agent. Specific steps are as follows:

[0029] Preparation of boron-affinity monolithic columns co-crosslinked with octavinyl-POSS and ethylene glycol dimethacrylate by in situ polymerization:

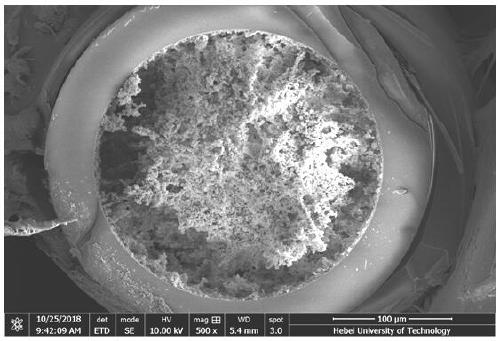

[0030] The mass percent crosslinking agent octavinyl-POSS 1.63% and ethylene glycol dimethacrylate 4.05%, functional monomer 3-acrylamidophenylboronic acid 3.08%, initiator azobisisobutyronitrile 0.26%, dissolved In the mixed porogen solution of 9.00% dimethyl sulfoxide and 81.98% chloroform as the porogen; ultrasonic (power 150W) was used to dissolve for 30 minutes to dissolve and clarify it, and then nitrogen gas was introduced to remove the porogen in the pre-polymerization solution. Oxygen, then inject the pre-polymerization liquid into the clean capillary, seal the two ends wi...

Embodiment 2

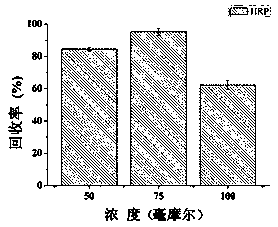

[0035]In solid-phase extraction, the adsorption of the target compound must go through four steps: activation, sample loading, rinsing, and elution, and the elution link is very important. The purpose of elution is to wash off the specifically adsorbed target molecules, and then evaluate the adsorption recovery effect according to the eluted amount of the target molecules. In order to clarify the impact of the concentration of the boron affinity monolithic column eluent on octavinyl-POSS and ethylene glycol dimethacrylate co-crosslinking on the recovery rate of horseradish peroxidase solid-phase microextraction, the present invention has different Concentration of the eluate was screened. The specific operation steps are as follows:

[0036] a. Preparation of monolithic column: Synthesize a boron-affinity monolithic column co-crosslinked with octavinyl-POSS and ethylene glycol dimethacrylate by the same method as above (Example 1).

[0037] b. Elution process: use 100 mL met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com