Preparation method of intelligent waterproof coating with self-healing function

A waterproof coating and self-healing technology, which is applied in coatings and other directions, can solve the problems of polymer cement-based waterproof coatings being not wear-resistant, shortening the service life of concrete materials, cracking and destroying concrete materials, etc., achieving strong UV resistance and reducing The cost of use, the effect of not easy to wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

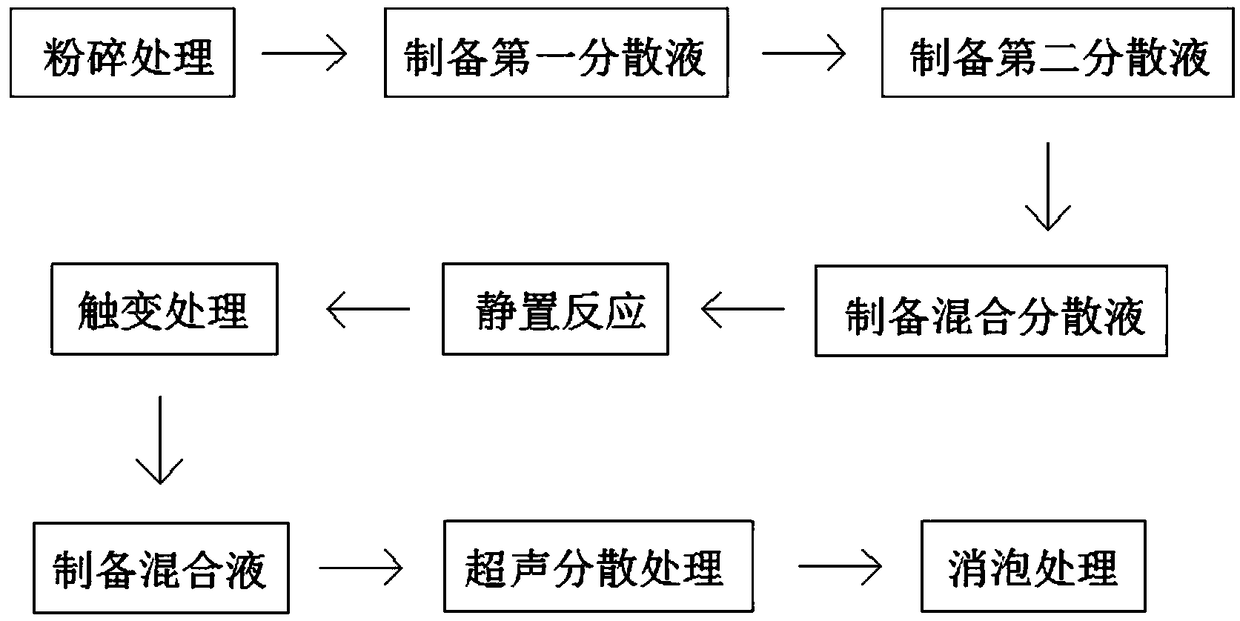

[0037] Preparation method of a self-healing intelligent waterproof coating

[0038] Step 1: Crushing

[0039] 10 parts by mass of titanium dioxide are subjected to micron-scale pulverization and nano-scale pulverization to make 7 parts by mass of titanium dioxide micron powder and 3 parts by mass of titanium dioxide nanopowder, the particle size of the titanium dioxide micron powder is 6 microns, and the titanium dioxide nanopowder The particle size is 52 nanometers;

[0040] Step 2: Prepare the first dispersion

[0041] Add titanium dioxide micron powder and 21 parts by mass of ethanol into the stirring tank and stir for 12 minutes, then ultrasonically disperse the mixture of titanium dioxide micron powder and ethanol to make the first dispersion liquid and take it out for use. The ultrasonic dispersion treatment time is 25 minutes. The stirring speed in the stirred tank is 280 rpm;

[0042] Step 3: Prepare the Second Dispersion

[0043] Titanium dioxide nano-powder and 1...

Embodiment 2

[0057] Preparation method of a self-healing intelligent waterproof coating

[0058] Step 1: Crushing

[0059] 12 parts by mass of titanium dioxide are subjected to micron-scale pulverization and nano-scale pulverization to make 9 parts by mass of titanium dioxide micron powder and 4 mass parts of titanium dioxide nanopowder, the particle size of the titanium dioxide micron powder is 6 microns, and the titanium dioxide nanopowder The particle size is 52 nanometers;

[0060] Step 2: Prepare the first dispersion

[0061] Add titanium dioxide micron powder and 25 parts by mass of ethanol into the stirring tank and stir for 12 minutes, then ultrasonically disperse the mixture of titanium dioxide micron powder and ethanol to make the first dispersion liquid, take it out for use, and ultrasonically disperse for 25 minutes. The stirring speed in the stirred tank is 280 rpm;

[0062] Step 3: Prepare the Second Dispersion

[0063] Titanium dioxide nano-powder and 12 parts by mass of...

Embodiment 3

[0077] Preparation method of a self-healing intelligent waterproof coating

[0078] Step 1: Crushing

[0079] 15 parts by mass of titanium dioxide are subjected to micron-scale pulverization and nano-scale pulverization to make 10 parts by mass of titanium dioxide micron powder and 5 parts by mass of titanium dioxide nanopowder. The particle size is 52 nanometers;

[0080] Step 2: Prepare the first dispersion

[0081] Add titanium dioxide micron powder and 27 parts by mass of ethanol into the stirring tank and stir for 12 minutes, then ultrasonically disperse the mixture of titanium dioxide micron powder and ethanol to make the first dispersion liquid and take it out for use. The ultrasonic dispersion treatment time is 25 minutes. The stirring speed in the stirred tank is 280 rpm;

[0082] Step 3: Prepare the Second Dispersion

[0083] Titanium dioxide nano-powder and 15 parts by mass of ethanol were added into the stirring tank and stirred for 22 minutes, and then the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com