Coating composition, preparation method of coating composition, coating part, preparation method of coating part, and household appliance

A composition and coating technology, applied in the coating and other directions, can solve the problems of poor temperature resistance, poor adhesion, and difficult to clean, and achieve the effects of good temperature resistance, good adhesion, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

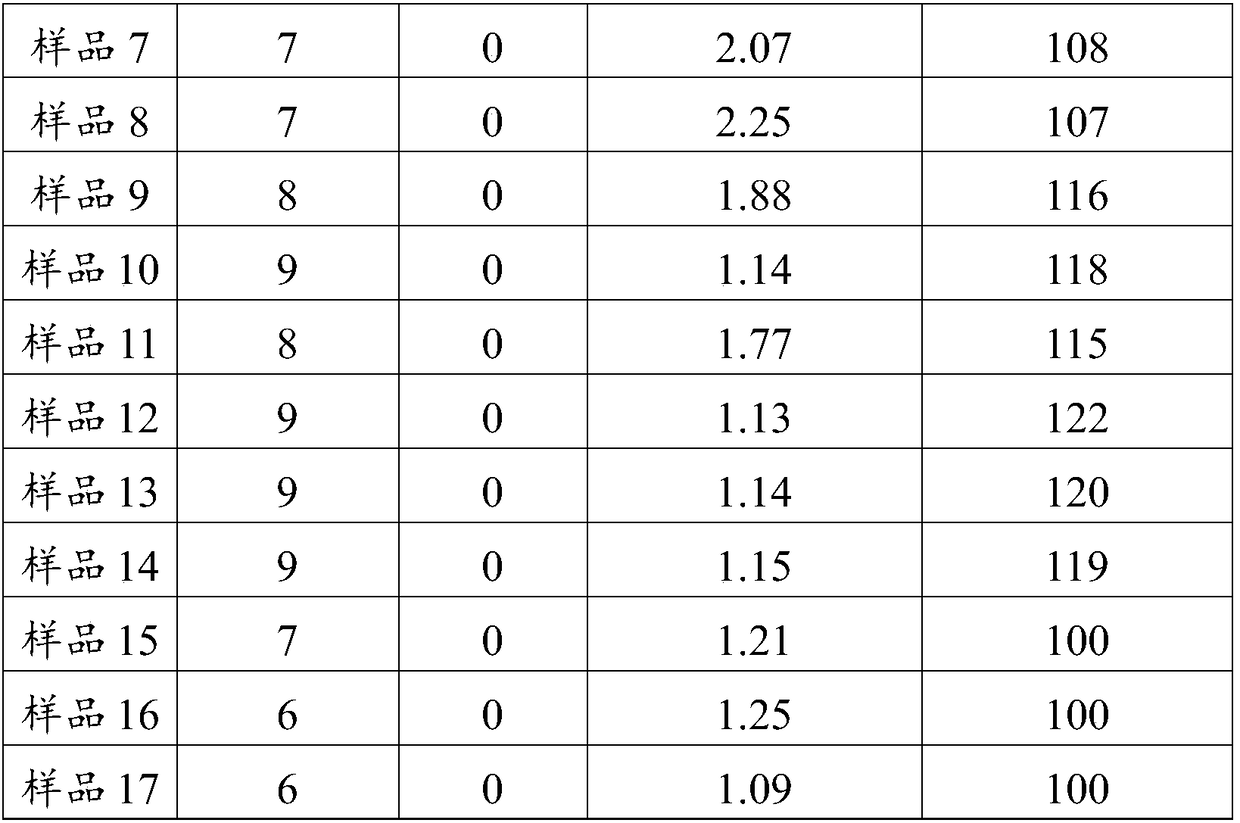

Examples

preparation example Construction

[0037] The raw materials for the preparation of the coating composition include polysilazane, polysiloxane and siloxane containing low surface energy side chains, and the polysilazane and polysiloxane undergo a copolymerization reaction to form polysilazane- A polysiloxane copolymer, the siloxane containing low surface energy side chains is mixed with the polysilazane-polysiloxane copolymer.

[0038] The raw materials for the preparation of the coating composition of the technical solution of the present invention include polysilazane, polysiloxane and siloxane containing low surface energy side chains, and the polysilazane and polysiloxane will undergo a copolymerization reaction to form polysiloxane. Silazane-polysiloxane copolymer. The polysilazane-polysiloxane copolymer has the advantages of high hardness, good adhesion and good temperature resistance, so that the coating formed by the coating composition has the advantages of high hardness, good adhesion and good temperat...

Embodiment 1

[0175] The preparation method of described coating composition comprises the following steps:

[0176] Preparation raw materials are provided, and the preparation raw materials include:

[0177] Polysilazane, the R of the polysilazane 1 is a hydrogen group, R 2 is a hydrogen group, R 3 is a hydrogen group, and the polysilazane accounts for 40% of the mass percentage of the preparation raw materials,

[0178] polysiloxane, the R of the polysiloxane 4 is a hydrogen group, R 5 It is an olefin, and the polysiloxane accounts for 40% of the mass percentage of the preparation raw material;

[0179] Triethoxy[4-(trifluoromethyl)phenyl]silane, which accounts for 20% of the mass percentage of the raw materials for the preparation.

[0180] Polysilazane and polysiloxane are placed in the reactor, and polysilazane and polysiloxane are mixed at a speed of 350 rpm, and the copolymerization reaction between polysiloxane and polysiloxane generates polysilazane. Siloxane-polysilazane co...

Embodiment 2

[0183] The preparation method of described coating composition comprises the following steps:

[0184] Preparation raw materials are provided, and the preparation raw materials include:

[0185] Polysilazane, the R of the polysilazane 1 is aryl, R 2 is a hydrogen group, R 3 is an alkylamino group, and the polysilazane accounts for 35% of the mass percent of the preparation raw materials,

[0186] polysiloxane, the R of the polysiloxane 4 is cycloalkane, R 5 is an alkylsiloxy group, and the polysiloxane accounts for 20% of the mass percentage of the preparation raw material;

[0187] 1,3-bis(3,3,3-trifluoropropyl)-1,1,3,3-tetramethyldisiloxane, which accounts for 12% of the mass percentage of the preparation raw materials;

[0188] Dibutyl ether, which accounts for 20% of the mass percentage of the preparation raw materials;

[0189] Cyclohexanone, which accounts for 10% of the mass percent of the preparation raw materials;

[0190] Dibutyltin dilaurate, which accounts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com