Method for processing surface textures of titanium cup

A technology of surface texture and treatment method, applied in the field of titanium cups, can solve the problems of insufficient surface hardness of titanium cups, single appearance, poor mechanical properties, etc., to achieve the effect of improving space utilization, avoiding mutual interference, and improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for treating the surface texture of a titanium cup, comprising the following steps:

[0051] (a) Take a stretched titanium cup, and degrease, clean, dry and polish the surface of the titanium cup 1;

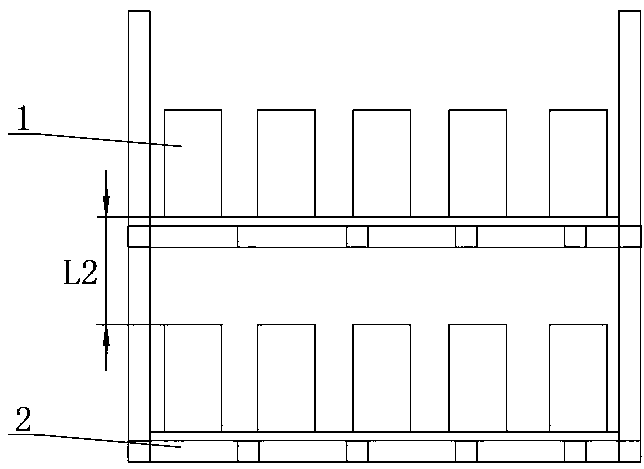

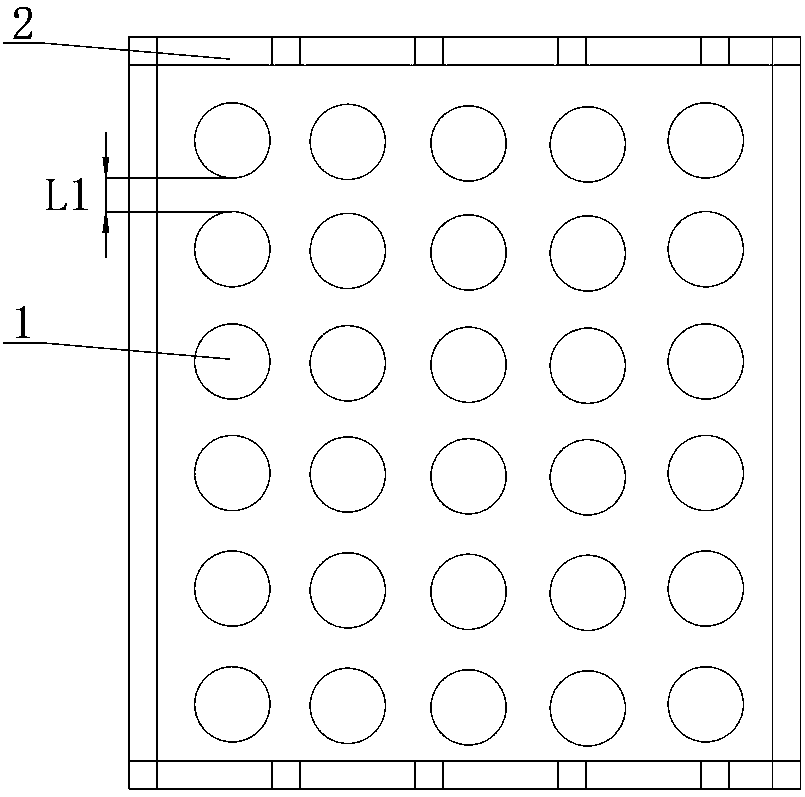

[0052] (b) Repeat the step (a) to process each titanium cup 1, put the treated titanium cup 1 into the support 2 and keep it stable, the support 2 is provided with a silicon carbide plate, and the titanium cup 1 is placed on the silicon carbide plate, and then put the bracket 2 into a vacuum furnace;

[0053] (c) Vacuumize the vacuum furnace by using the vacuum device A until the vacuum degree of the vacuum furnace is less than 0.1Pa, and then heat the vacuum furnace while keeping the vacuum degree less than 0.1Pa. Control the heating rate so that the vacuum furnace is heated to 200°C within 15 minutes and kept for 30 minutes;

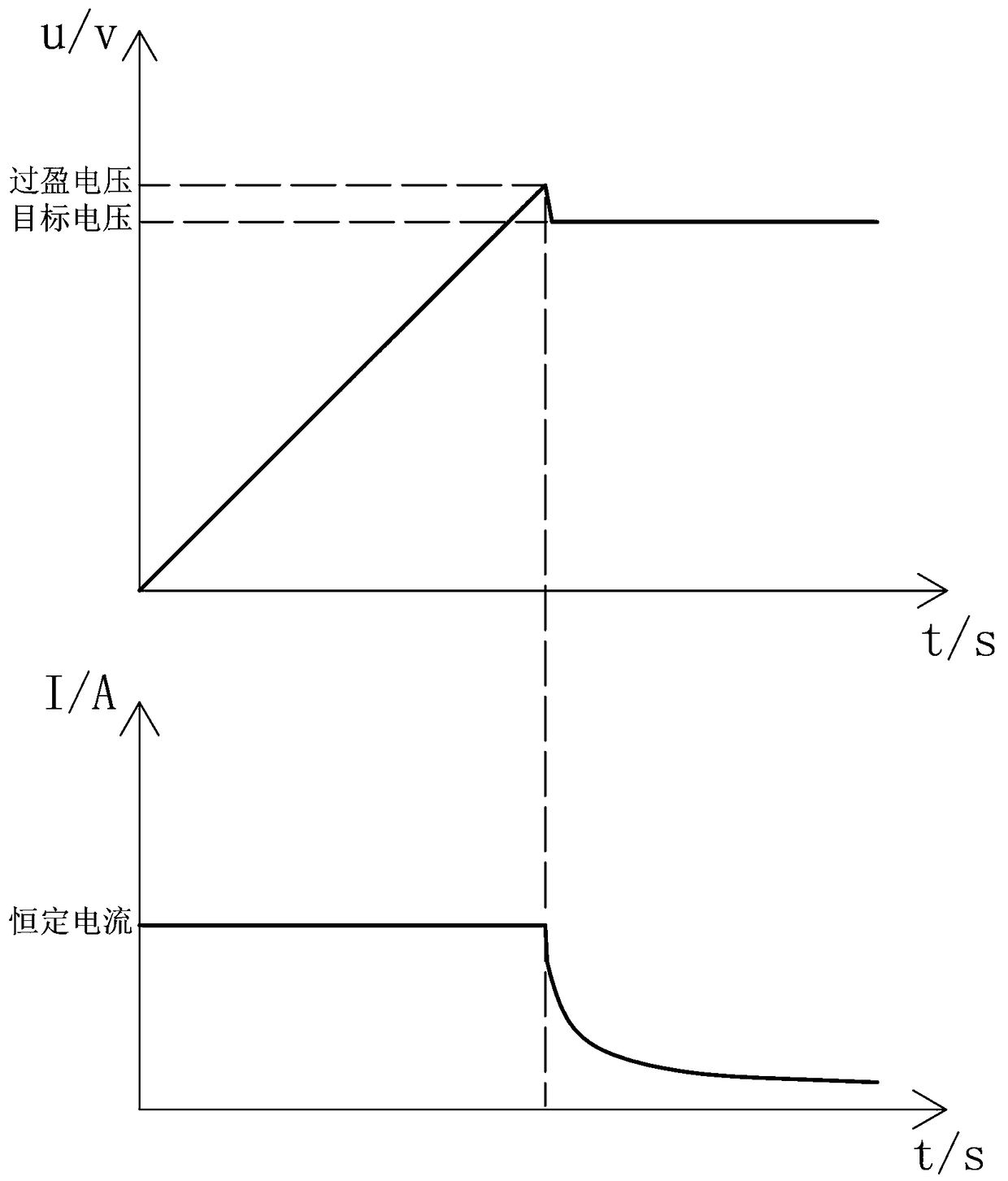

[0054] (d) Vacuumize the vacuum furnace by using vacuum device B, so that the vacuum degree in the vacuum furnace reaches 0.01Pa, and r...

Embodiment 2

[0080] A method for treating the surface texture of a titanium cup, comprising the following steps:

[0081] (a) Take a stretched titanium cup, and degrease, clean, dry and polish the surface of the titanium cup 1;

[0082] (b) Repeat the step (a) to process each titanium cup 1, put the treated titanium cup 1 into the support 2 and keep it stable, the support 2 is provided with a silicon carbide plate, and the titanium cup 1 is placed on the silicon carbide plate, and then put the bracket 2 into a vacuum furnace;

[0083] (c) Vacuumize the vacuum furnace by using the vacuum device A until the vacuum degree of the vacuum furnace is less than 0.1Pa, and then heat the vacuum furnace while keeping the vacuum degree less than 0.1Pa. Control the heating rate so that the vacuum furnace is heated to 210°C within 17.5 minutes and kept for 25 minutes;

[0084] (d) Vacuumize the vacuum furnace by using vacuum device B, so that the vacuum degree in the vacuum furnace reaches 0.01Pa, and r...

Embodiment 3

[0110] A method for treating the surface texture of a titanium cup, comprising the following steps:

[0111] (a) Take a stretched titanium cup, and degrease, clean, dry and polish the surface of the titanium cup 1;

[0112] (b) Repeat the step (a) to process each titanium cup 1, put the treated titanium cup 1 into the support 2 and keep it stable, the support 2 is provided with a silicon carbide plate, and the titanium cup 1 is placed on the silicon carbide plate, and then put the bracket 2 into a vacuum furnace;

[0113] (c) Vacuumize the vacuum furnace by using the vacuum device A until the vacuum degree of the vacuum furnace is less than 0.1Pa, and then heat the vacuum furnace while keeping the vacuum degree less than 0.1Pa. Control the heating rate so that the vacuum furnace is heated to 220°C within 20 minutes and maintained for 20 minutes;

[0114] (d) Vacuumize the vacuum furnace by using vacuum device B, so that the vacuum degree in the vacuum furnace reaches 0.01Pa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com