Method for blocking water through artificial bend at river canal estuary sewage treatment facility grit basin

A sewage treatment and river estuary technology, which is applied in water conservancy projects, water conservancy engineering equipment, dams, etc., can solve the problems of difficulty in building grit chambers, great influence, and poor sewage treatment effect, and achieve good treatment effect and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

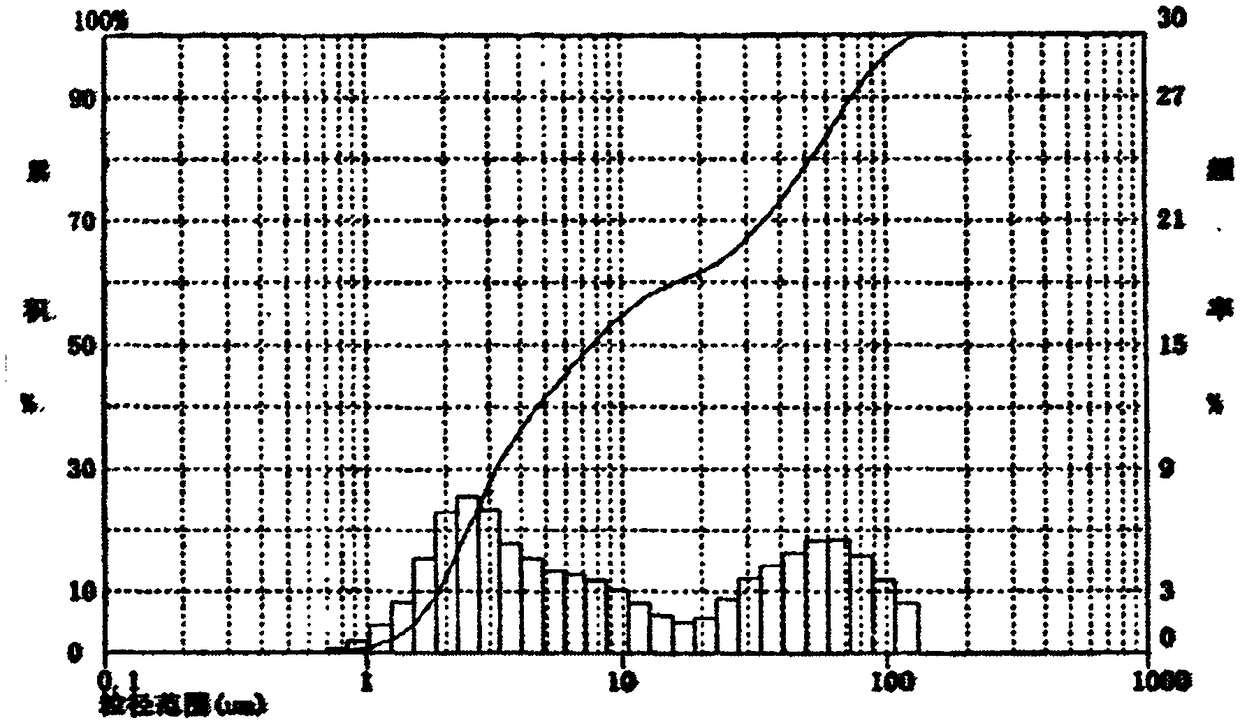

[0026] The daily average sediment content of the river estuary sewage at the urban-rural junction is about 43 mg / L, and the particle size distribution is shown in the figure. Due to the influence of flow rate and aeration in the sewage treatment system, 17.67% of the mud and sand in the sewage did not settle in the sedimentation tank and the biochemical reaction tank. This part of the small particle size mud and sand will not affect the river to block the biochemical reaction pipeline and aeration tank , but go with the water flow, so the lost mud and sand can be ignored. 82.33% of the mud and sand (with a particle size of 5μm-100μm) in the second drain sewage treatment system were deposited in the reactor. In addition if figure 1 As shown, 30% of the mud and sand particle size is less than or equal to 5 μm, so the mud sand with a particle size of less than or equal to 5 μm is not considered.

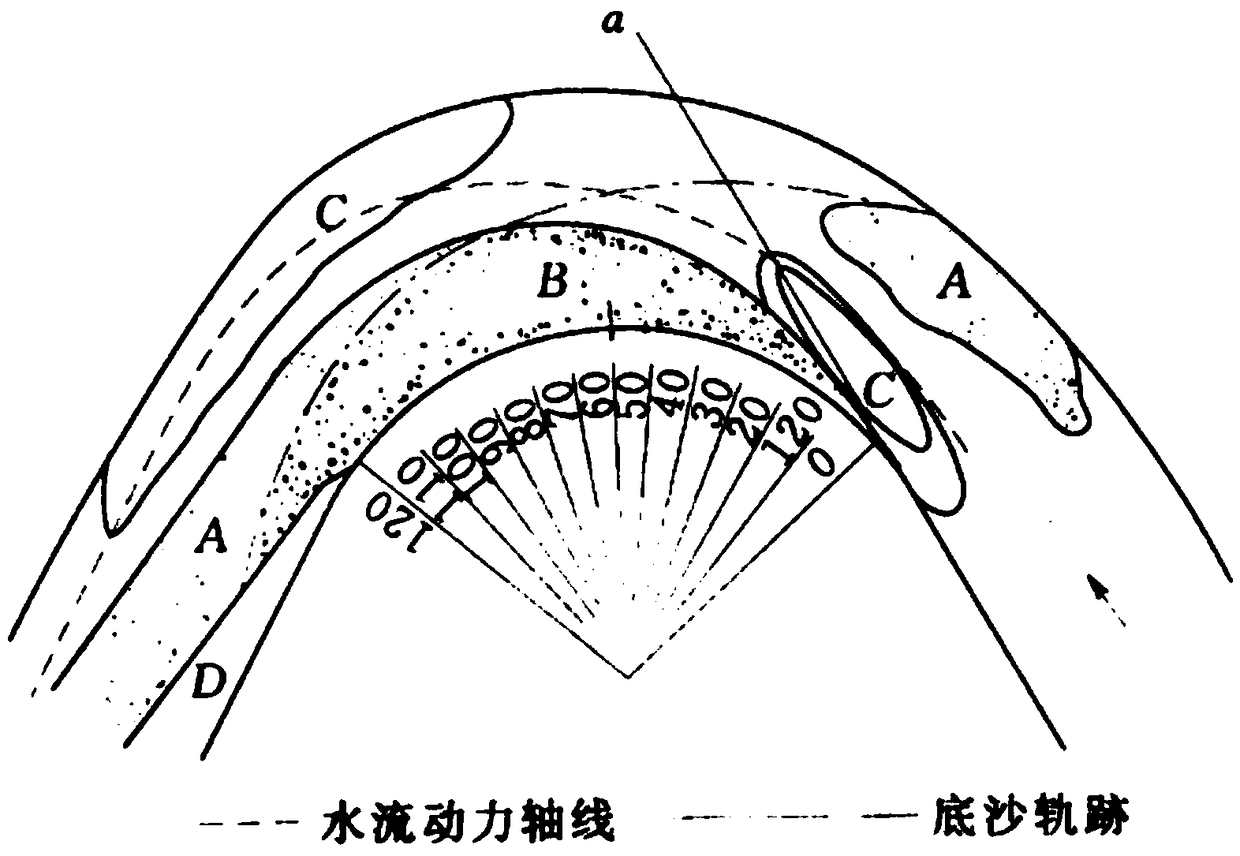

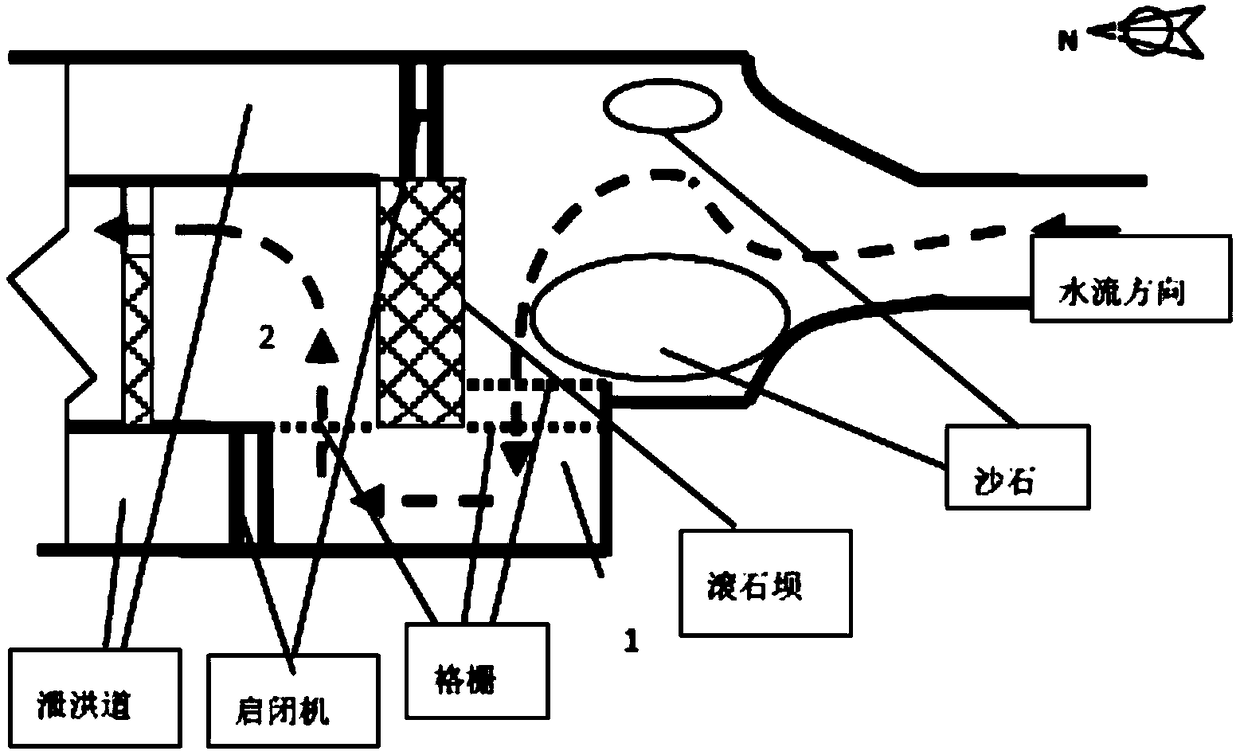

[0027] The sewage treatment grit chamber at the estuary adopts the method of back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com