Sample processing cabinet for detecting zearalenone in corn and processing method

A technology of erythralenone and sample processing, which is applied in the preparation of test samples, grain processing, sampling, etc., can solve the problems of high detection cost, high detection frequency, inaccurate detection results, etc., and achieve accurate detection results, The effect of reducing the detection frequency and improving the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

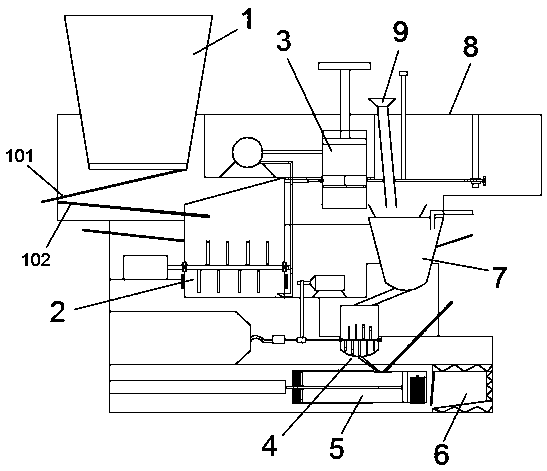

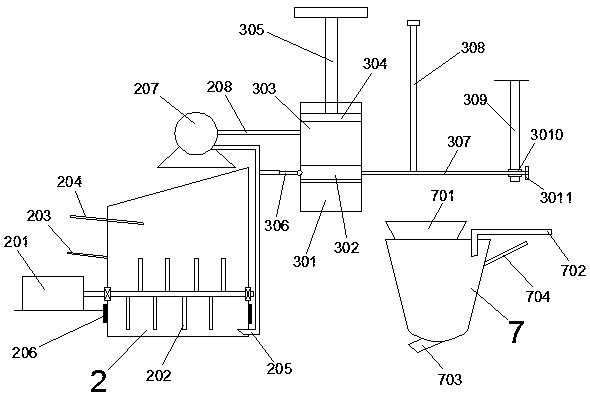

[0048] Such as Figure 1-6 As shown, a sample processing cabinet for detection of erythralenone in corn includes a cabinet body 8 with a plurality of partition spaces inside, and the side of the cabinet body 8 has a cabinet door that is opened to show the internal partition space; The partition space of 8 is respectively provided with a corn pulverizer 1 for rough grinding and crushing of corn feed samples and a wet mill pulverizer 7 for secondary fine grinding of pulverized corn samples, and the wet pulverized mixture of wet pulverizer 7 is rinsed , drying after filtering, that is to say, the processing of the sample is completed, and a stirring culture tank 2 and a filter press 3 are respectively arranged in the partition space in the cabinet body 8, wherein, an inclined sloping tank 2 and a pressure filter 3 are arranged below the discharge port of the corn grinder 1. The screen 101, the lowest point of the screen 101 extends out of the cabinet 8, so that the corn particles...

Embodiment 2

[0053] The main structure of this embodiment is the same as that of Embodiment 1, the difference is that this embodiment is a further improvement to the wet mill 7 and the filter 5, and the wet mill 7 is respectively provided with a filter for adding The carbon disulfide connection pipe 702 of carbon disulfide and the methanol connection pipe 704 adding methanol, the pulverized mixture enters the filter 5 through the material discharge port 703 at the bottom of the wet mill pulverizer 7 to filter;

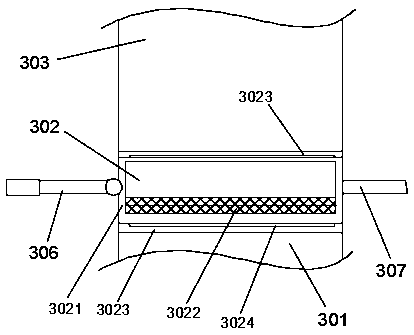

[0054] The filter 5 includes an outer sleeve 504 with one end open and an inner sleeve 501 that is closed at both ends and is slidably connected with the outer sleeve 504. A return spring 503 is arranged at the bottom of the outer sleeve 504, and the return spring 503 is connected to the inner sleeve 501. One end in the outer sleeve 504 is connected. When the return spring 503 is in a free state, the inner sleeve 501 is provided with a bar-shaped groove 506 on the side wall outside ...

Embodiment 3

[0056] The main structure of this embodiment is the same as that of Embodiment 2, the difference is that this embodiment is a further improvement on the structure of the dryer 6 that cooperates with the filter 5, and the inner sleeve 501 is provided with a drying The dryer 6, the dryer 6 includes a closed cavity, the inner wall of the cavity is provided with an electric heating wire II603, the cavity has an opening facing the inner sleeve 501, and the opening is provided with a strip that blocks the opening Cloth curtain 601, when the hydraulic cylinder 502 pushes the piston 507 to the end of the inner sleeve 501, it continues to elongate, thereby driving the inner sleeve 501 to move forward, and when the piston rod of the hydraulic cylinder 502 stretches out to the limit position, The filter frame 508 on the inner sleeve 501 is heated in the cavity of the dryer 6 . After the heating is completed, the hydraulic cylinder 502 drives the piston rod to retract, and the inner sleev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com