Salinity detection device for cooking and manufacturing method of salinity detection device

A detection device and technology of saltiness, applied in the direction of manufacturing tools, glass manufacturing equipment, applications, etc., can solve the problems of no real control or at least clarity, no cooking saltiness detection device, and hidden dangers of hygiene, so as to achieve easy detection and Maintain and enhance the consumer experience, with good targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

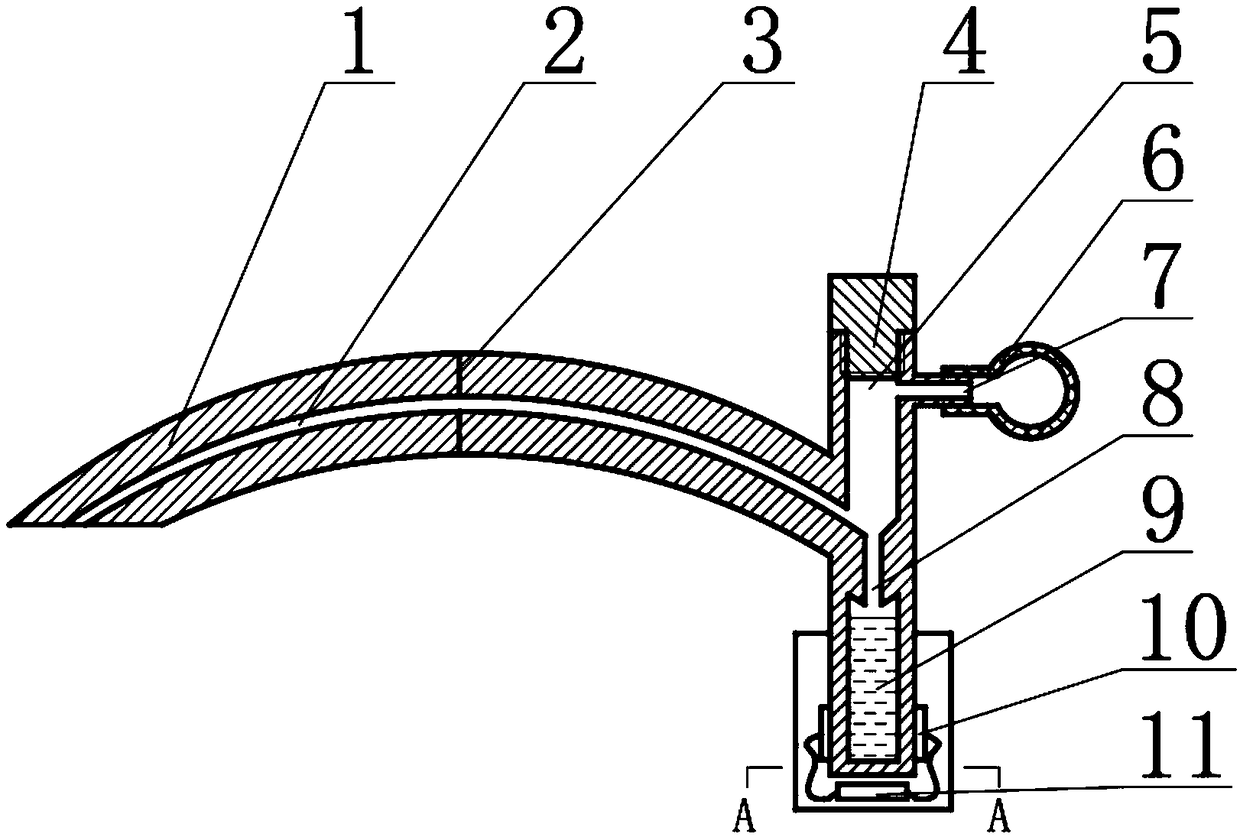

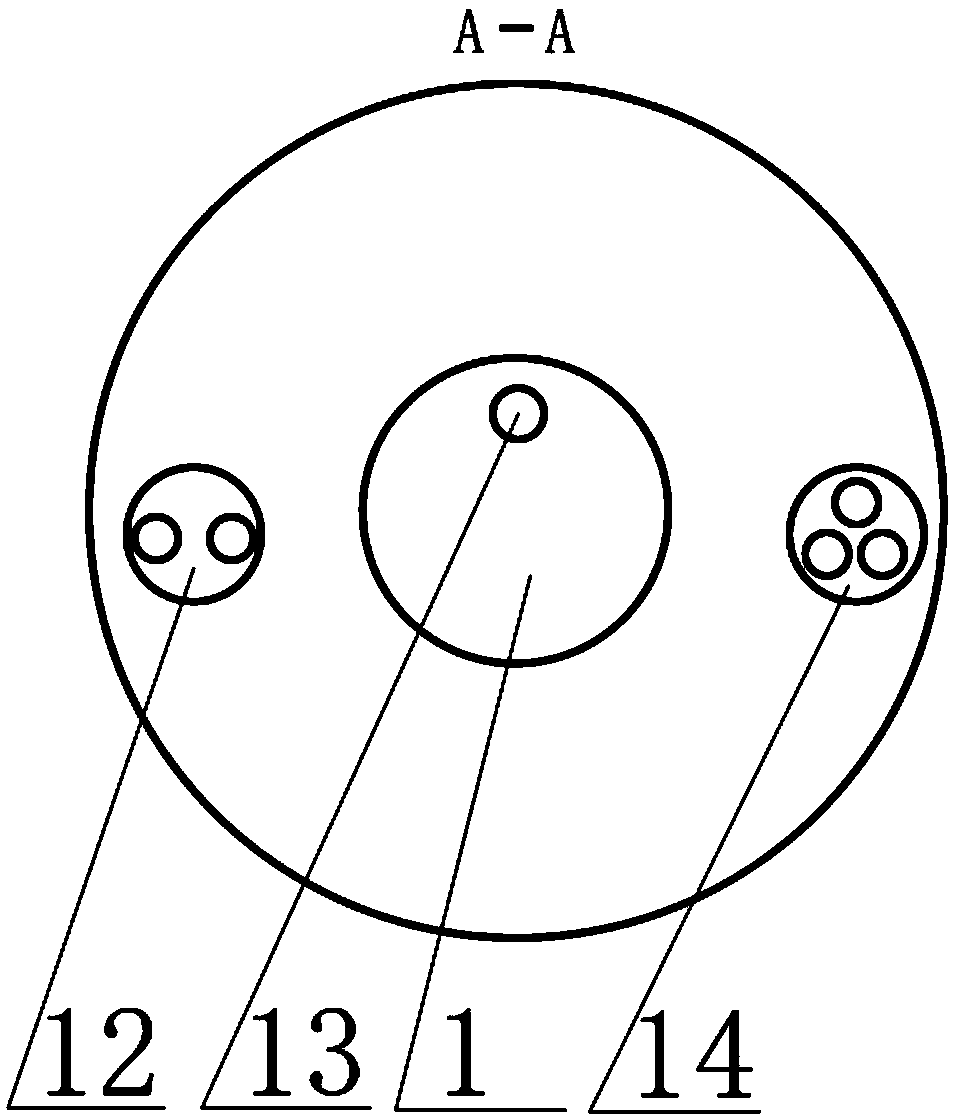

[0028] A detection device for cooking saltiness, the detection device includes an arch bridge-shaped siphon 2 with a radius of 0.1mm on the left, a liquid replenishment port 5 on the top, an air delivery hole 7 connected to the air bag 6 on the right, and a bottom Set with built-in 1ml (1cm 3 ) a glassware body 1 of a functional liquid container 9 containing an aqueous solution of 2% silver nitrate and 1% litmus by mass fraction, a sealing screw plug 4 matching the liquid replenishment port 5, and a correspondingly close functional liquid container matching the functional liquid container 9 9 The refraction detection device 10 in the bottom 1 / 3 area and the control detection center 11 matched with the refraction detection device 10; the arch bridge-shaped siphon 2 is provided with a standard scale 3 31.8mm away from the entrance of the arch-bridge siphon 2 (corresponding to a single suction volume of 1mm 3 ); the top of the functional liquid container 9 is provided with a one-...

Embodiment 2

[0042] The whole is consistent with Example 1, the difference is:

[0043] The radius of the arch bridge shape siphon 2 is 0.2mm; the bottom of the functional liquid container 9 is provided with a built-in 5ml (5cm 3 ) an aqueous solution containing 2% silver nitrate and 1% litmus by mass fraction;

[0044] Wherein the manufacturing process of said glassware body 1 comprises the following steps:

[0045] 1) Raw material preparation

[0046] ① Raw material preparation: Prepare 80g of silicon dioxide and 20g of sodium oxide in parts by weight;

[0047] ② Preparation of tooling mold materials: prepare enough paraffin, enough clay, enough quartz powder, enough ammonium chloride, enough water glass with a modulus of 2.8, enough hydrochloric acid, arch bridge-shaped siphon 2 and one-way through hole 8 Compatible ceramic filament cores, molds compatible with the shape and size of the glassware body 1;

[0048] 2) Formwork core manufacturing

[0049] ②Mix the water glass, quartz ...

Embodiment 3

[0053] The whole is consistent with Example 1, the difference is:

[0054] Raw material preparation: Prepare 90g of silicon dioxide and 10g of sodium oxide

[0055] The radius of the arch bridge-like siphon 2 is 0.5mm; the bottom of the functional liquid container 9 is provided with a built-in 1ml (1cm 3 ) an aqueous solution containing 2% silver nitrate and 1% litmus by mass fraction;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com