Method for predicting residual life of in-service denitration catalyst based on actual operating conditions

A denitrification catalyst and actual operation technology, applied in the direction of chemical property prediction, chemical instruments and methods, separation methods, etc., can solve the problems of untimely judgment of catalyst failure point and inability to predict the remaining life of denitrification catalyst in service, so as to reduce environmental risks and equipment risks, reducing the generation of solid hazardous waste, and avoiding waste

Active Publication Date: 2019-03-01

ZHENGZHOU NORMAL UNIV

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to solve the problems of the existing traditional methods, such as untimely judgment of catalyst failure point and inability to predict the remaining life of denitrification catalysts in service, the present invention proposes a method for predicting the remaining life of denitrification catalysts in service based on actual operating conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0023] A method for predicting the remaining life of an in-service denitration catalyst based on actual operating conditions, the method steps are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

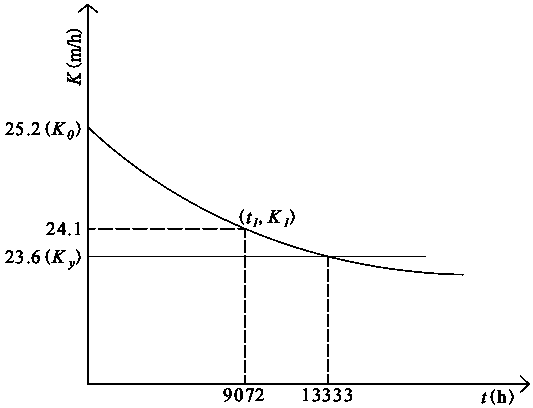

The invention provides a method for predicting the residual life of an in-service denitration catalyst based on actual operating conditions. The method includes sampling and detecting the in-service denitration catalyst to measure the current activity K1 of the in-service denitration catalyst; collecting data such as average flue gas flow rate V, average coal consumption mass M, initial activity K0 of the denitration catalyst, the current in-service time T1 of the denitration catalyst and the like of the unit in a coal-fired power plant, substituting the collected and detected data into a formula to calculate a correction coefficient lambda to obtain an in-service denitration catalyst deactivation graph; and predicting the residual life ts of the in-service denitration catalyst according to the catalyst activity threshold Ky provided by a manufacturer when the denitration catalyst is initially mounted, and calculating the residual life ts of the in-service catalyst. The method realizesthe prediction of the residual life of the in-service denitration catalyst, provides a guarantee for the power plant to replace the deactivated catalyst in time at a catalyst failure point, so that the waste of catalyst potential is avoided, and the generation of solid hazardous waste is reduced.

Description

technical field [0001] The invention belongs to the technical field of life management of denitrification catalysts, and in particular relates to a method for predicting the remaining life of denitrification catalysts in service based on actual operating conditions. Background technique [0002] SCR flue gas denitrification technology is the most widely used and mature flue gas denitrification technology in coal-fired power plants at home and abroad. In the actual production process of the power plant, with the increase of time, the harsh operating environment will gradually cause the abrasion of the SCR denitrification catalyst, microscopic pore blockage, arsenic poisoning, alkali metal poisoning, etc., so that the active sites on the surface of the catalyst will continue to decrease. The life cannot be used up to standard. [0003] At present, whether the denitrification catalyst has reached its service life and whether the power plant needs to replace the catalyst layer ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G16C20/30B01D53/86B01D53/90

CPCB01D53/8628B01D53/90B01D2251/2062B01D2258/0283

Inventor 李会吉孙海杰陈凌霞邵冰琪刘娜

Owner ZHENGZHOU NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com