A carbon film spray tin printed circuit board preparation process

A technology of printed circuit board and preparation process, which is applied in the direction of printed circuit manufacturing, printed circuit, and secondary treatment of printed circuit, etc. It can solve the problem of no copper surface roughness, unfavorable carbon film board curing effect, unfavorable carbon film and copper surface Bonding etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

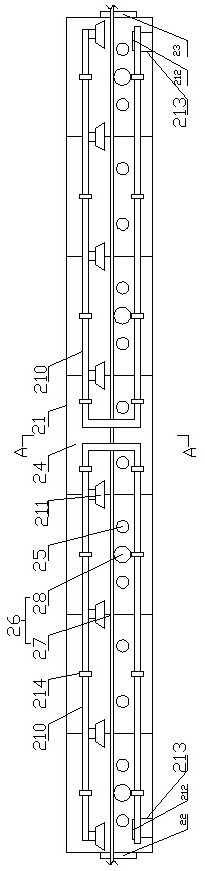

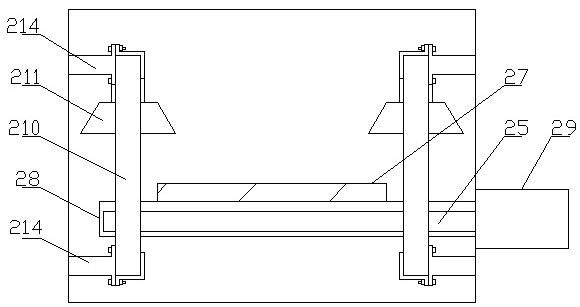

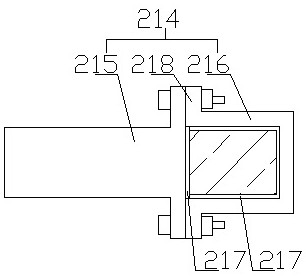

[0050] In order to make the technical solution of the present invention more clearly, the present invention will be further described below with reference to the drawings, and the techniques of the technical features of the present invention are equivalent replacement and conventional reasoning results in the scope of the invention.

[0051] A carbon film spray printing circuit board preparation process, the steps are as follows:

[0052] (1) Preprocessing: The copper plate matrix is used for mechanical grinding and cleaning the copper plate base before printing and carbon film is printed;

[0053] (2) Preparation Printing Net Edition: 220 ocolina net plate, coated 30UM thickness sealing gel;

[0054] (3) Printing and soldering: printing ink in the printing net; printed on the printing net plate with printing ink is printed on the copper matrix; the copper plate is printed, the solder welding character;

[0055] (4) Curing bake: Add the copper plate base to the seven-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com