Flame-retardant composition and flame-retardant synthetic-resin composition

A technology for synthesizing resin and composition, applied in the direction of fire retardant coatings, etc., can solve the problems of resin coloring, lower dispersibility, longer processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

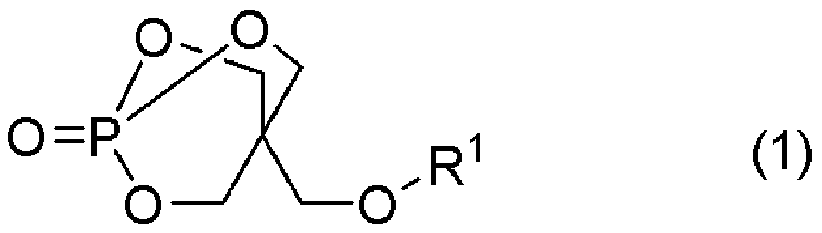

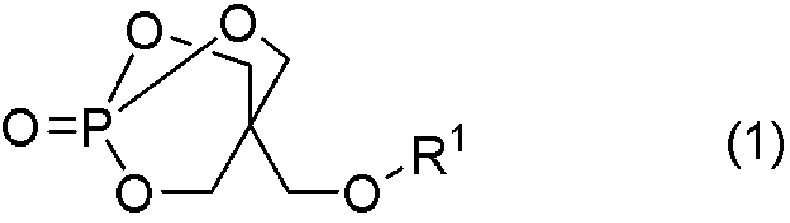

Image

Examples

Embodiment 1~5 and comparative example 1~3

[0099] The flame retardant composition of the present invention and the comparative flame retardant composition were prepared with the formulations described in Table 1.

[0100] Table 1

[0101]

[0102] *1: Melamine pyrophosphate: The ratio of pyrophosphate to melamine is 1:2 by molar ratio

[0103] *2: Piperazine pyrophosphate: The ratio of pyrophosphate to piperazine is 1:1 in molar ratio

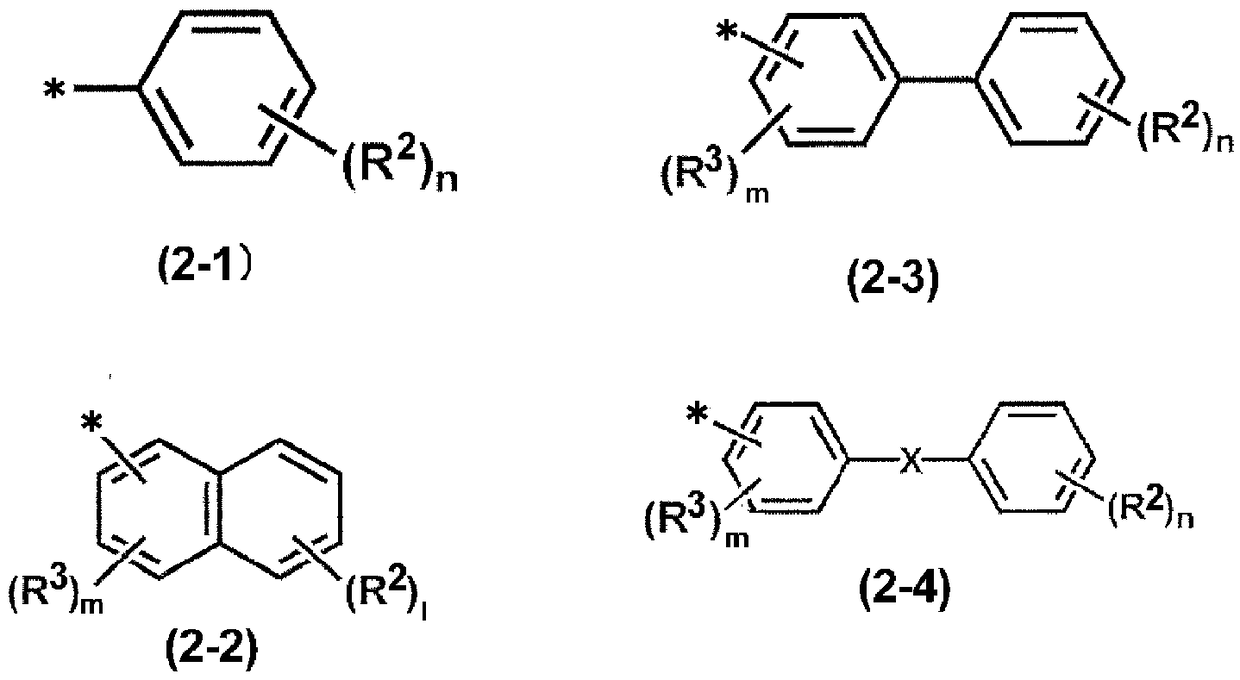

[0104] *3: Among compound No.2-1, the compound where n is 0

[0105] *4: KF-96 (Dimethicone Oil / Shin-Etsu Chemical Co., Ltd.)

[0106] *5: KF-99 (Methyl hydrogen silicone oil / Shin-Etsu Chemical Co., Ltd.)

Embodiment 6~16 and comparative example 4~9

[0108] 0.1 parts by mass of calcium stearate (organic crystal nucleating agent), four [ 0.1 parts by mass of 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid methyl]methane (phenolic antioxidant), tris(2,4-di-tert-butylphenyl)phosphite (Phosphorus-based antioxidant) 0.1 mass parts, glycerol monostearate (lubricant) 0.3 mass parts of the polypropylene resin composition obtained by adding Example 1 in the compounding ratio (mass %) described in Table 2 or 3, respectively -5 and the flame-retardant compositions obtained in Comparative Examples 1-3, the flame-retardant synthetic resin compositions of Examples 6-16 and the flame-retardant synthetic resin compositions of Comparative Examples 4-9 were obtained. Regarding the flame retardant composition, the flame retardant composition obtained in Example 1 is referred to as flame retardant composition-1, and the flame retardant composition obtained in Example 2 is referred to as flame retardant composition-2 , the flame retardant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com