an air separation device

An air separation and equipment technology, applied in specific gas purification/separation, oxygen preparation, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of low oxygen concentration, small oxygen enrichment, and difficulty in oxygen , to achieve the effect of improving separation effect, simple equipment and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

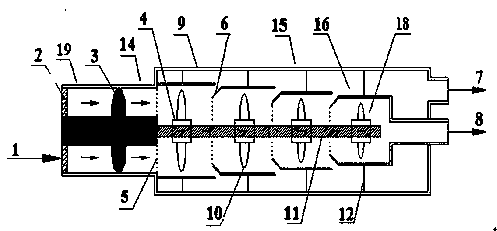

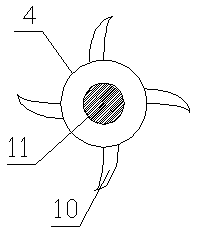

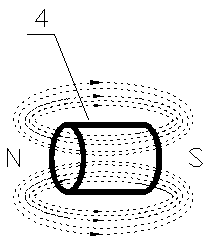

[0038] use figure 1 Oxygen separator and air filter 2 are made of stainless steel wire mesh with a pore diameter of 5mm. The blower 3 adopts an axial flow fan. The inlet pressure of the blower 3 is -0.1kPa, and the outlet pressure of the blower 3 is 13kPa. The length of 4 is 6 times of fixed shaft 11 radiuses. The impeller 10 has 4 blades, the corona assembly 5 is provided with 12 corona rods 17, the distance between the end of the corona rod 17 close to the fixed shaft 11 and the outer surface of the fixed shaft 11 is 30m, the length of the ionization separation cylinder 16 is 4 times the length of 4, the radius of the ionization separation cylinder 16 is 30mm shorter than the blade radius, after the air is filtered by the filter 2, it is pressurized by the blower 3 to 13kPa, and enters the ionization-magnetic field oxygen enrichment section, and the ionization-magnetic field oxygen enrichment section is set to 4 level, the oxygen concentration of the enriched oxygen flow is...

Embodiment 2

[0040] use Figure 5 Oxygen separator and air filter 2 are made of stainless steel wire mesh with a pore diameter of 4mm, the blower 3 is an axial flow fan, the inlet pressure of the blower 3 is -0.1kPa, the outlet pressure of the blower 3 is 11kPa, the magnetic assembly The length of 4 is 6 times of fixed shaft 11 radiuses. The impeller 10 has 4 blades, the corona assembly 5 is provided with 12 corona rods 17, the distance between the end of the corona rod 17 close to the fixed shaft 11 and the outer surface of the fixed shaft 11 is 30m, the length of the ionization separation cylinder 16 is 4 times of the length, the radius of the ionization separation cylinder 16 is 35mm shorter than the blade radius. The magnetic field transformation assembly 13 adopts a magnetic shield, and the length of the magnetic field transformation assembly 13 is 1 / 2 of the length of the oxygen-enriched assembly 18; the center distance between the magnetic field transformation assembly 13 and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com