Pole piece slurry, electrode plate and pole piece slurry manufacturing method

A production method and electrode sheet technology, which can be applied to battery electrodes, circuits, electrical components, etc., and can solve problems such as battery stability and safety impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] According to the preparation method provided by the present invention, step 1: after the conductive agent and the electrode active material are premixed, the polymer modifier is added to the premixed conductive agent and electrode active material for surface modification, Finally the binder and the solvent are added. The polymer modifier is attached to the surface of the conductive agent as the surface protection layer of the conductive agent, which reduces the gas production in the high temperature environment of the lithium-ion battery, increases the stability of the battery cell, and improves the surface properties of the conductive agent and the relationship between the conductive agent and the solvent. compatibility between them.

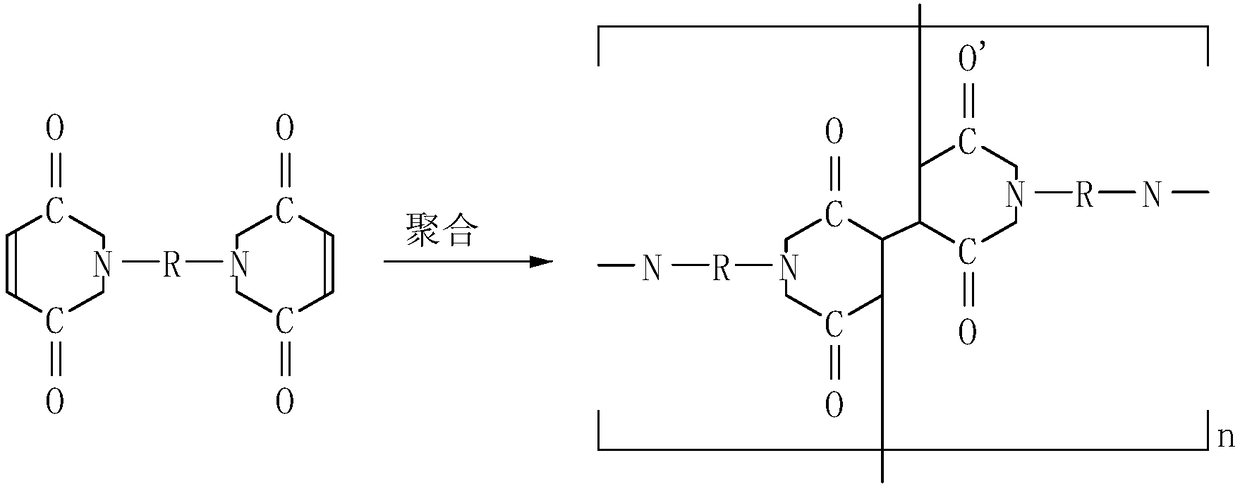

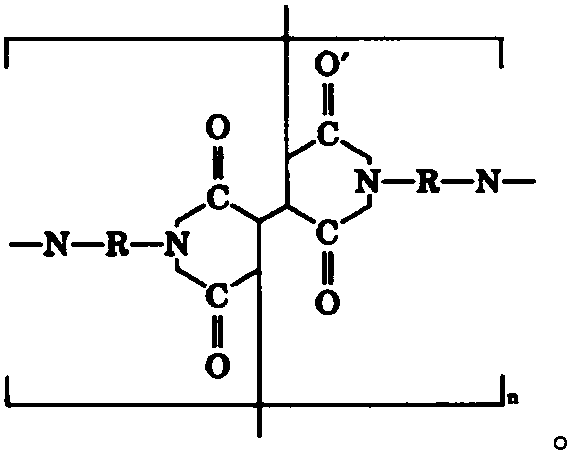

[0029] figure 1 It is a schematic diagram of the molecular structure generation of the polymer modifier provided by the present invention. The polymer modifier is Depend on (Bismaleimide (Bismaleides)) polymerized. where R can be ...

Embodiment

[0035] The cathode material is LiCoO 2 Structure, according to mass percentage, 96% of positive electrode material, 2% of conductive carbon black, 0.5% of polymer modifier, and 1.5% of PVDF are added into N-methylpyrrolidone (NMP) solvent to form the positive electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com