Medical deflectable grinding head

A grinding head and outer tube technology, applied in the field of medical deflectable grinding head, can solve problems such as unreliable stability, hidden safety hazards, and affecting surgical safety, and achieve the effect of improving surgical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

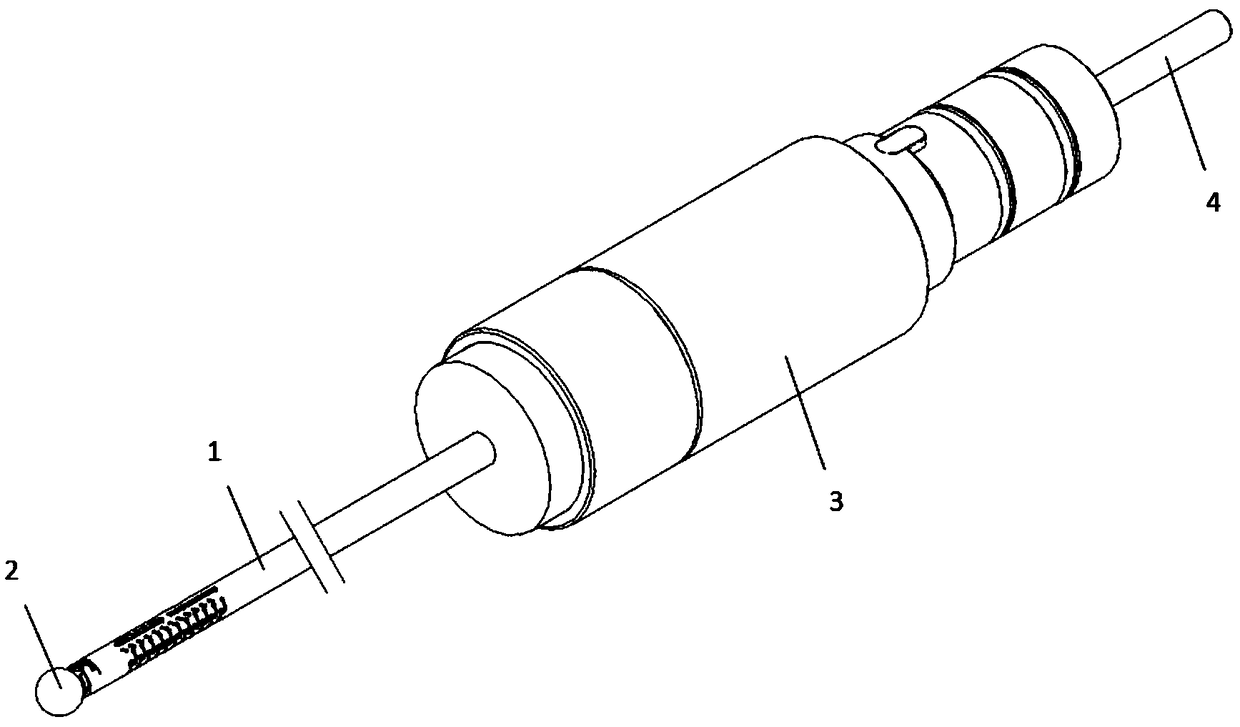

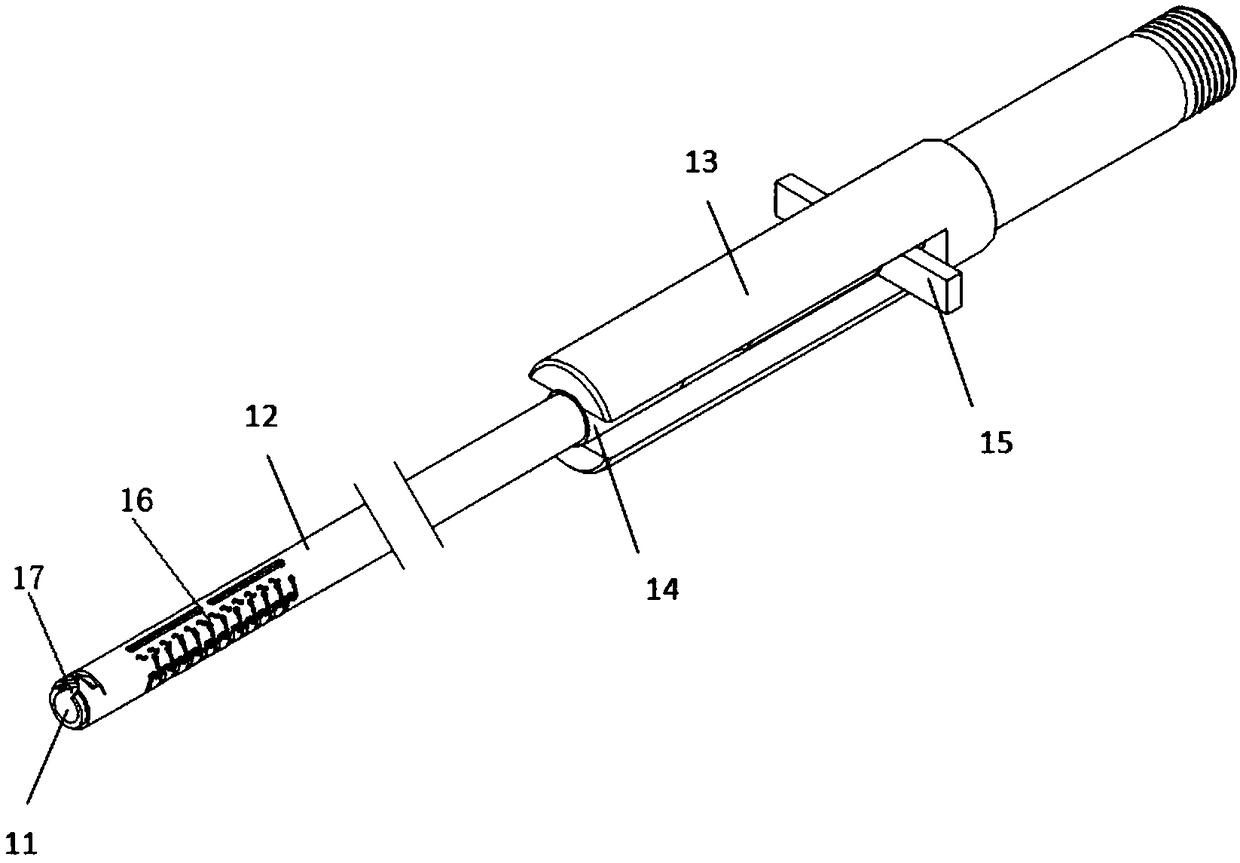

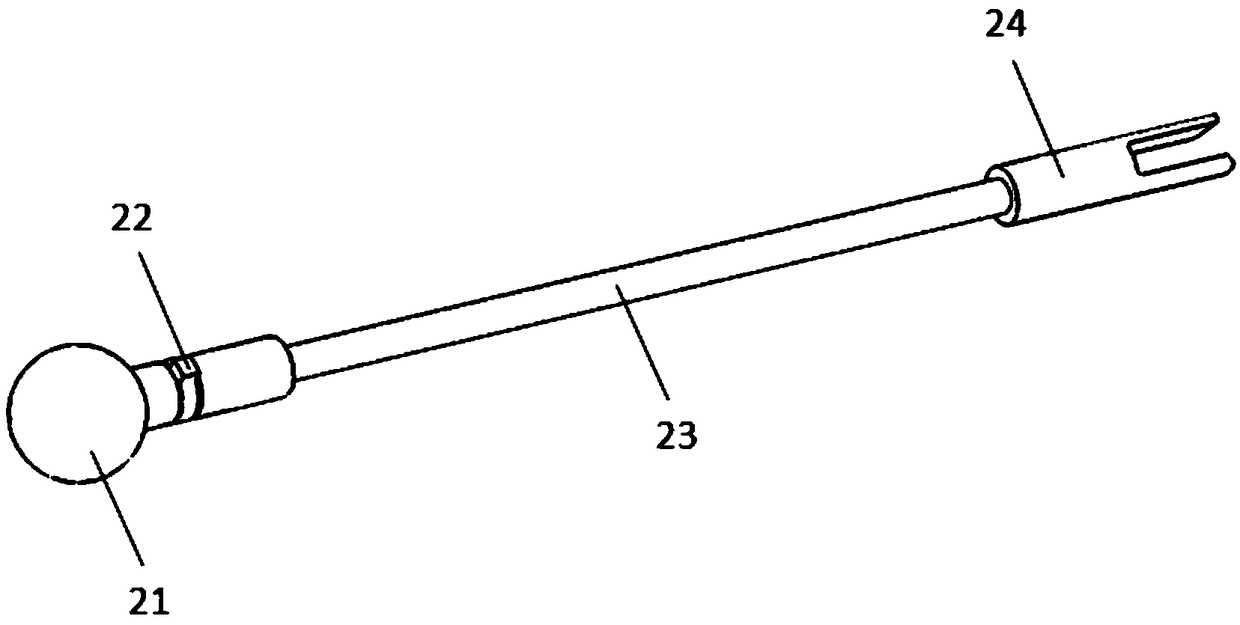

[0051] This embodiment is a preferred medical deflectable grinding head.

[0052] like Figure 1 to Figure 8 As shown, the medical two-way deflectable grinding tool of this embodiment includes a deflectable tube assembly 1, a grinding head assembly 2 installed at the far end of the deflectable tube assembly 1, a proximal handle 3 and a deflectable tube assembly. 1 internal transmission assembly 4. The deflectable tube assembly 1 can be driven by the handle 3 to deflect in two directions, thereby driving the front end grinding head 21 to deflect. The deflectable tube assembly 1 is composed of inner and outer tubes, and the distal end is fixedly connected (welded). Both the inner tube 11 and the outer tube 21 of the deflectable tube assembly 1 have a proximal notch 16 and a distal notch 17 in the axial direction, and the notches of the inner tube 21 and the outer tube 22 are relatively distributed.

[0053] The deflectable tube assembly 1 comprises an inner tube 11 , an outer...

Embodiment 2

[0059] This embodiment is an alternative embodiment of the first embodiment, which only optimizes the structure of the barb-shaped incision and the straight-shaped incision on the inner tube and the outer tube.

[0060] In this example, if Figure 9-10 As shown, the width of the barb-shaped incision on the inner tube is wide in the middle and narrow at both ends, and two straight bar-shaped incisions are provided; the barb-shaped incision on the outer tube 12 is wide in the middle and narrow at both ends, and two bar-shaped incisions are provided Straight cuts, wherein the straight cuts on the inner tube 11 and the exterior 12 are arranged on opposite sides.

[0061] In this embodiment, the cutting barbs of the inner tube and the outer tube are less cut on both sides, more cut in the middle, more uncut parts on both sides are reserved, and the middle is the maximum bending point of the deflectable tube assembly, so as not to increase bending resistance. Improve the connection...

Embodiment 3

[0063] This embodiment is an alternative embodiment of the first embodiment, which only optimizes the structure of the barb-shaped incision and the straight-shaped incision on the inner tube and the outer tube.

[0064] In this example, if Figure 11-12 As shown, the width of the barb-shaped incision on the inner tube is wide at the far end and narrow at the proximal end, and a straight bar-shaped incision with a larger width (compared with Embodiments 1 and 2) is set; the inverted hook on the outer tube 12 The hook-shaped incision is wide at the far end and narrow at the proximal end, and two straight strip-shaped incisions with larger widths (compared with Embodiments 1 and 2) are provided, wherein the straight strip-shaped incisions on the inner tube 11 and the appearance 12 are set on the same side.

[0065] In this embodiment, the wide straight seam of the inner tube and the outer tube cooperates with the cutting width of the proximal end to gradually decrease, which red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com