Novel high-speed eddy slurrying system and use method thereof

A vortex, high-speed technology, applied in the field of new high-speed eddy current pulping system, can solve the problems of insufficient cleaning inside the pulping machine, inconvenient filling of pulping machine materials, shortening the service life of the pulping machine, etc., and achieve reasonable equipment layout design , Save material loss and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

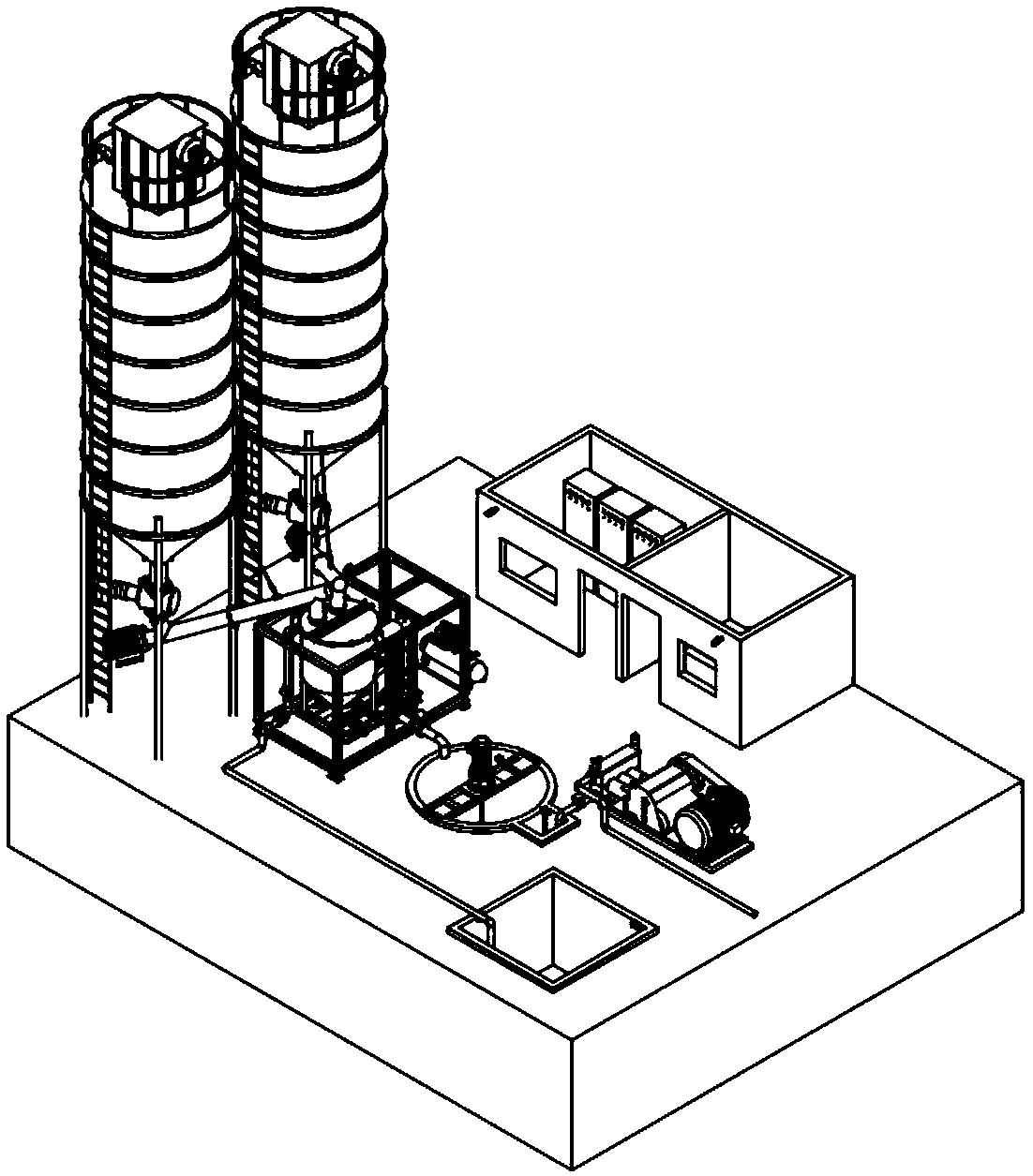

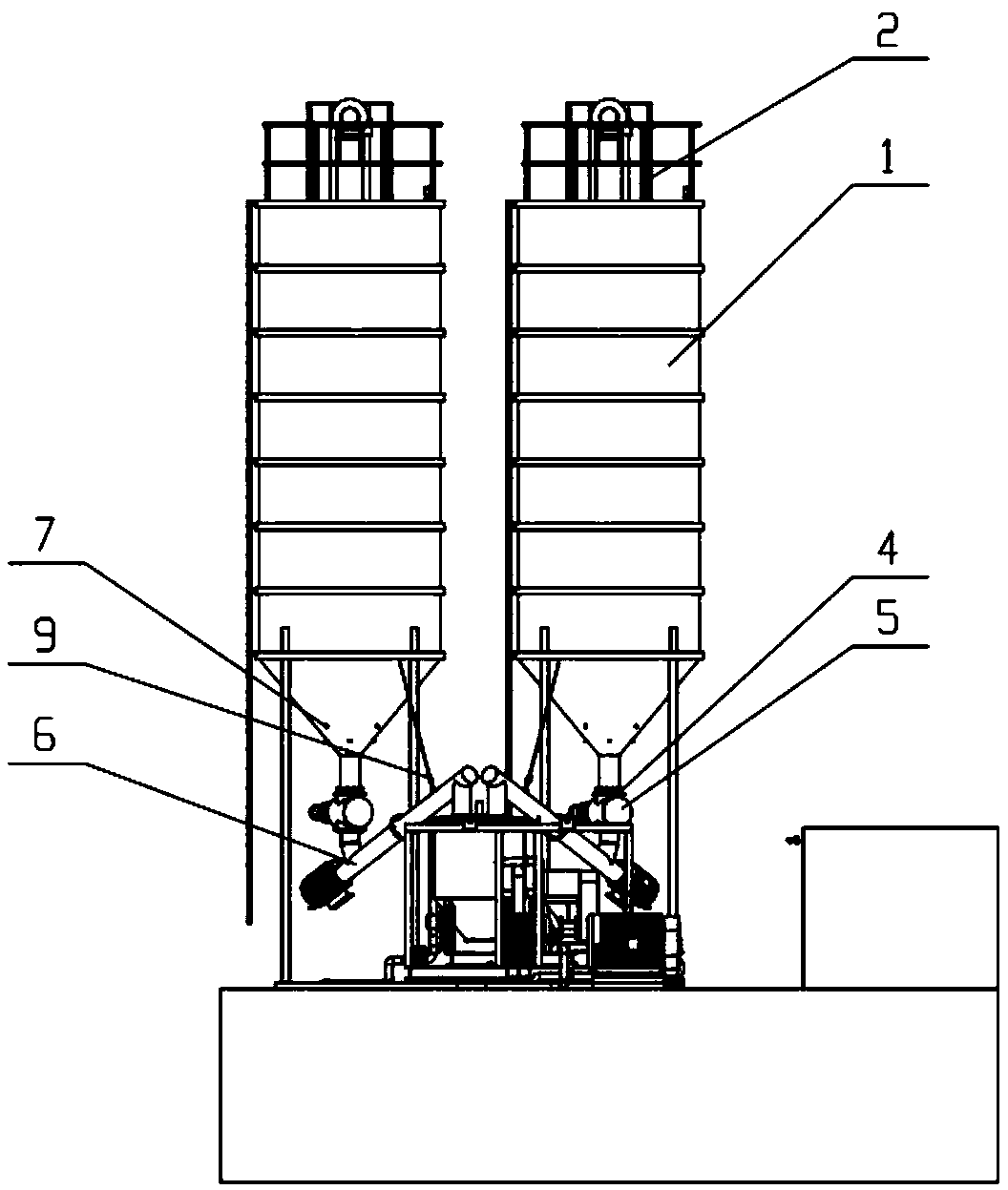

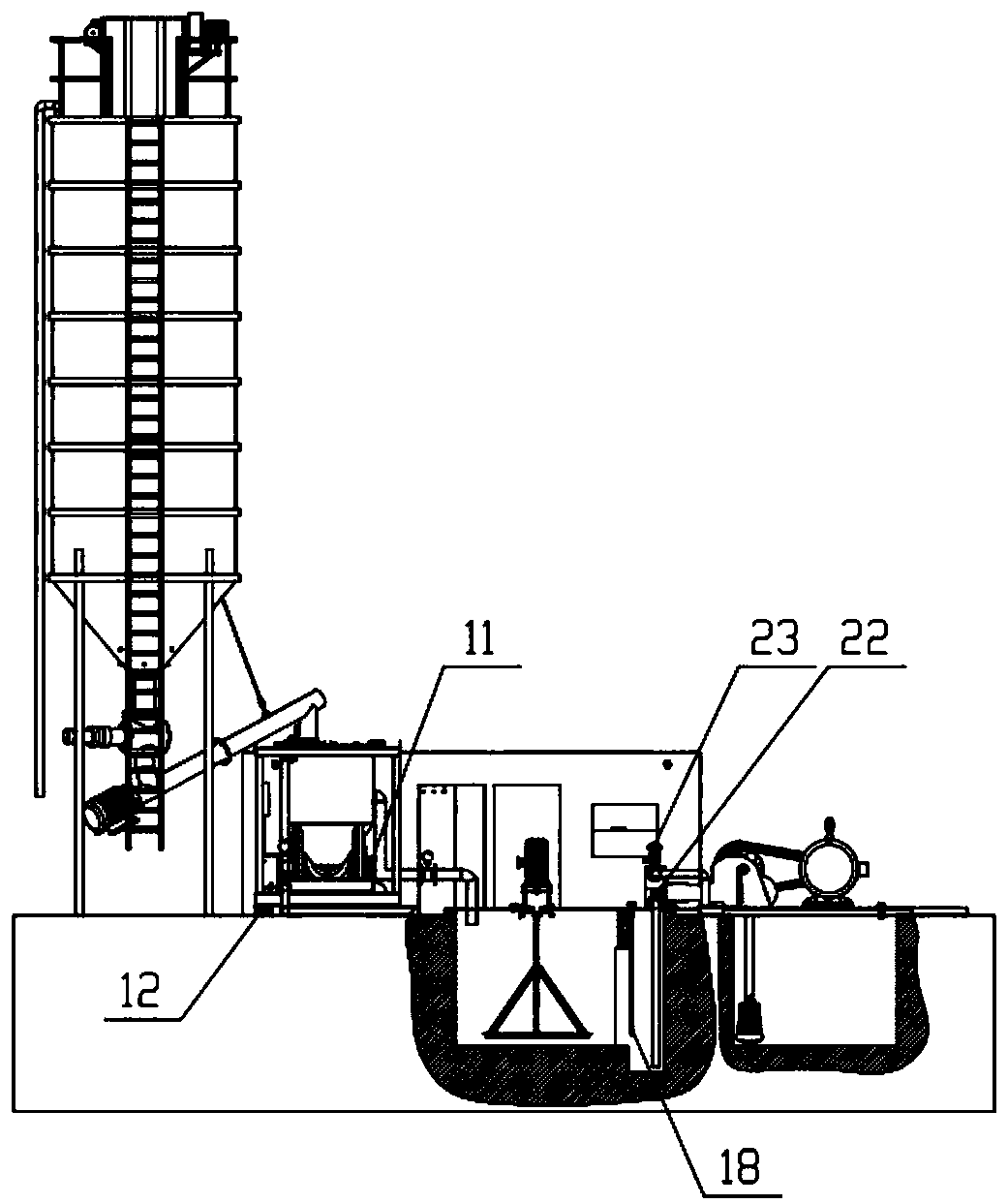

Embodiment 1

[0037] A new type of high-speed eddy current pulping system is provided, including pulping equipment, grouting equipment, a slurry storage tank 13 and a water supply tank, the pulping equipment includes a storage bin 1 and a high-speed vortex pulping machine 8, and the storage A frequency conversion feeder 5 is fixedly connected to the bottom of the silo 1, and a screw conveyor 6 is fixedly connected to the lower surface of the frequency conversion feeder 5, and the screw conveyor 6 is fixedly connected to the high-speed eddy current pulper 8 A water inlet pipe and an overflow pipe are fixedly connected to the high-speed vortex pulping machine 8, the water inlet pipe is placed in the water supply pool, the water supply pump 19 is fixedly connected to the water inlet pipe, and the overflow pipe is placed in the water supply pool. In the grout storage tank 13 described above, the grouting equipment includes a high-pressure grouting pump 21, and the high-pressure grouting pump 21 ...

Embodiment 2

[0046] Also provided is a method for using a novel high-speed vortex pulping system, the method comprising the following steps:

[0047] a. The material enters the high-speed vortex pulper 8 from the storage bin 1 through the frequency conversion feeder 5 and the screw conveyor 6, and the water in the water supply tank enters the high-speed vortex pulper 8 through the water inlet pipe, and the high-speed vortex pulper The machine 8 fully mixes the material and water into a high-concentration slurry;

[0048] b. The high-concentration slurry enters the slurry storage tank 13 through the overflow pipe, and then flows out through the slurry inlet pipe and the slurry outlet pipe;

[0049] c. Open the pneumatic butterfly valve 11 to let the remaining slurry in the high-speed vortex pulper 8 flow out, close the pneumatic butterfly valve 11, and let the water in the water supply pool enter the high-speed vortex pulper 8 through the water inlet pipe;

[0050] d. Open the pneumatic bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com