Bimetallic composite oxide catalyst and preparation and application methods thereof

A technology of composite oxides and catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor stability, high yield and selectivity of MPC In order to achieve the effects of good stability, low cost and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

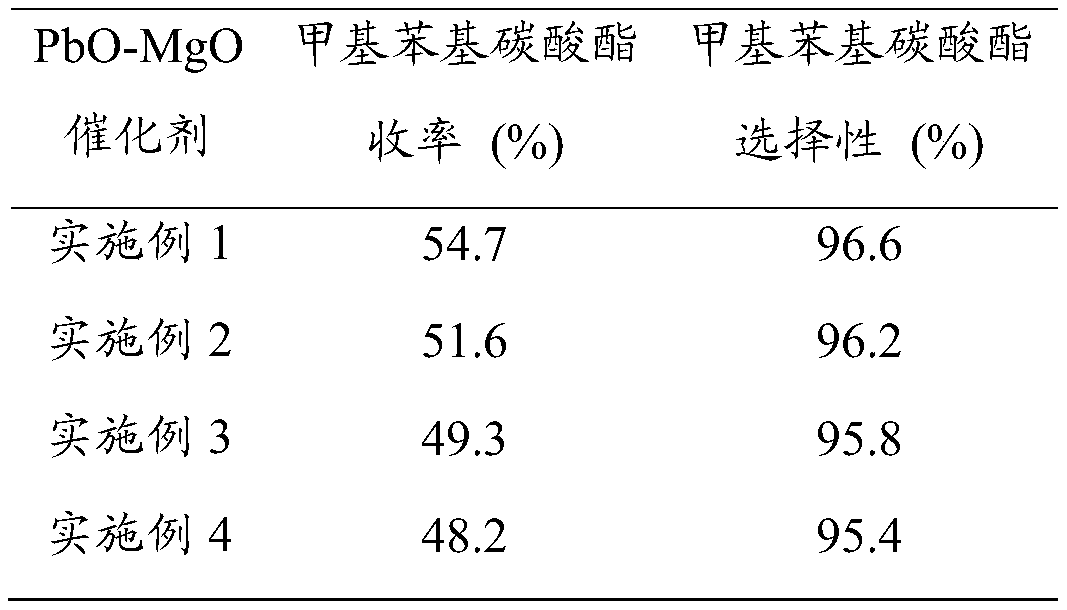

Embodiment 1

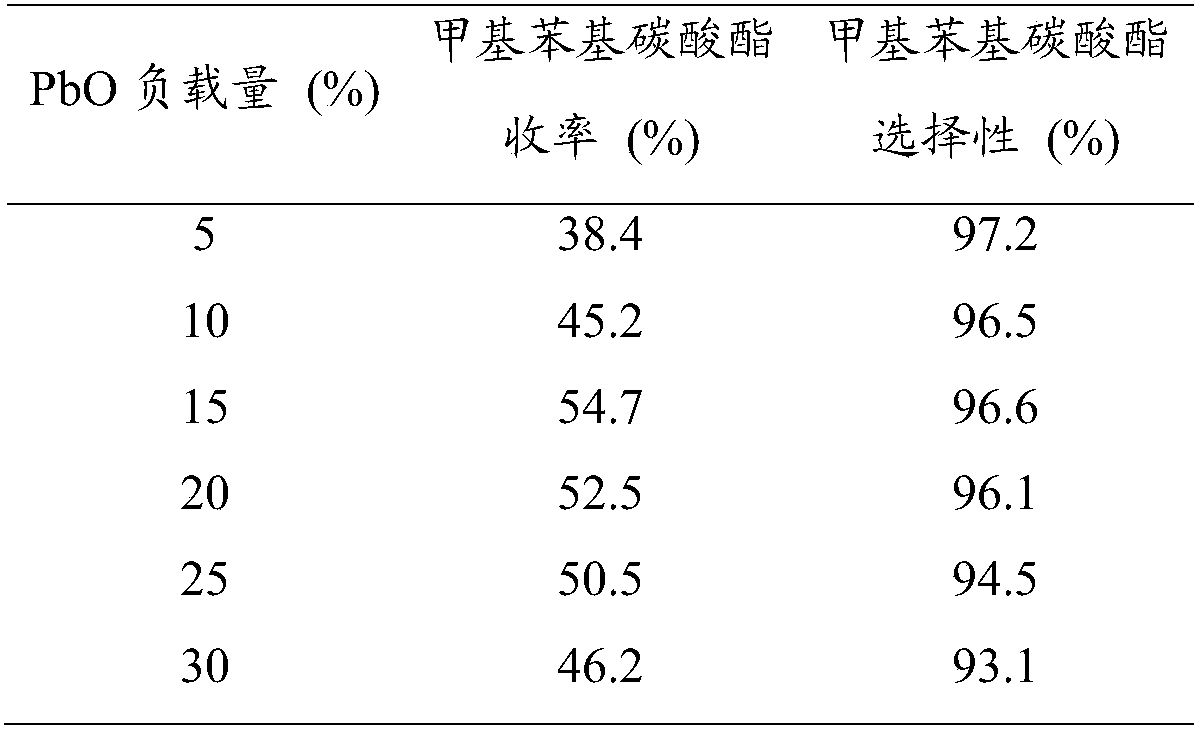

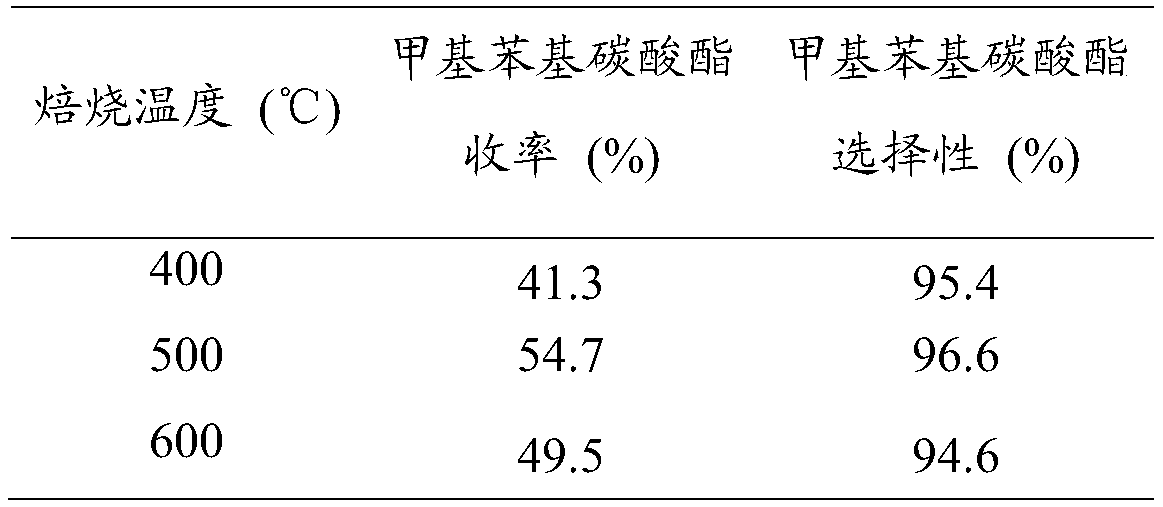

[0022] Add 18.4g of magnesium nitrate, 1.3g of lead nitrate and 24.0g of CTAB into 80mL of deionized water, heat to 80°C to dissolve the solid completely; under stirring, slowly add ammonium hydroxide dropwise until the pH of the solution reaches 10.0, and the prepared The white suspension was aged at 50°C for 4h, transferred to a polytetrafluoroethylene hydrothermal kettle, hydrothermally crystallized at 120°C for 24h, filtered, washed, dried at 110°C for 24h, and then calcined at 500°C for 5h to obtain PbO-MgO catalyst with 15% PbO loading.

Embodiment 2

[0024] The preparation steps of the PbO-MgO catalyst are the same as those in Example 1, except that magnesium chloride is used as the magnesium source to prepare a PbO-MgO catalyst with a PbO loading of 15%.

Embodiment 3

[0026] The preparation steps of the PbO-MgO catalyst are the same as in Example 1, but lead acetate is used as the lead source to prepare a PbO-MgO catalyst with a PbO loading of 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com