Preparation method for catalyst for removing NOx

A catalyst and carrier technology, applied in the field of catalyst preparation, can solve the problems of long time, waste of water resources, environmental protection pressure, complicated procedures, etc., and achieve the effects of saving resources, easier control of active component content, and easy operation of the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

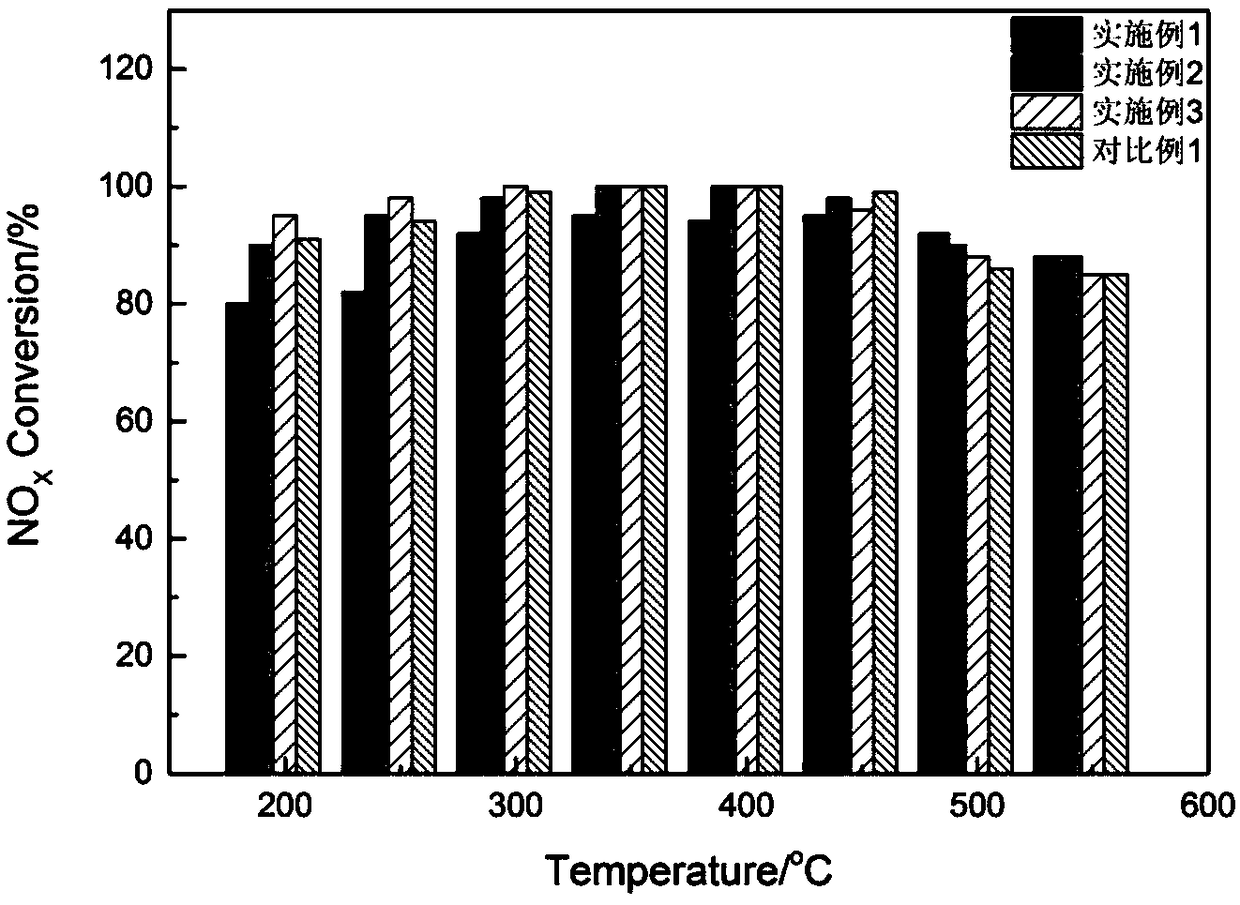

Embodiment 1

[0027] The cordierite carrier was placed in a 0.01 mol / L copper nitrate solution to stand still, and the amount of metal impregnated by the carrier was 1.5% of the dry weight of the subsequently coated molecular sieve. Then take it out and dry it at a drying temperature of 50°C for 2 hours. Then, the CHA molecular sieve slurry with adjusted configuration is coated on the dried carrier, and the coated carrier is kept at a drying rate of 0% for aging for 1 hour, and finally the drying and roasting temperature is 450 ° C. Time is 3h to get sample 1.

Embodiment 2

[0029] The aluminum titanate carrier was placed in a 0.5 mol / L copper acetate solution and allowed to stand still, and the amount of metal impregnated into the carrier was 2% of the dry weight of the subsequently coated molecular sieve. Then take it out and bake it at a drying temperature of 65°C for 1 hour. Then apply the adjusted CHA molecular sieve slurry on the dried carrier, keep the coated carrier at a drying rate of 25%, and age it for 4 hours, and finally dry and roast it at 500°C. Time is 2h to get sample 2.

Embodiment 3

[0031] The silicon carbide carrier was placed in a 1mol / L copper sulfate solution and allowed to stand, and the amount of metal impregnated by the carrier was 4% of the dry weight of the subsequently coated molecular sieve. Then take it out and dry it at a drying temperature of 80°C for 0.5h. Then apply the adjusted CHA molecular sieve slurry on the dried carrier, keep the coated carrier at a drying rate of 50%, and age it for 8 hours, and finally dry and roast it at 600°C. Sample 3 was obtained for 1 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com