Odor absorption waterproof material and preparation method thereof

A waterproof material and absorbing technology, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of failure to meet the use requirements, easy to be affected by the weather, poor fire and flame retardancy, etc., and achieve good water resistance And viscosity, improve waterproof performance, improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

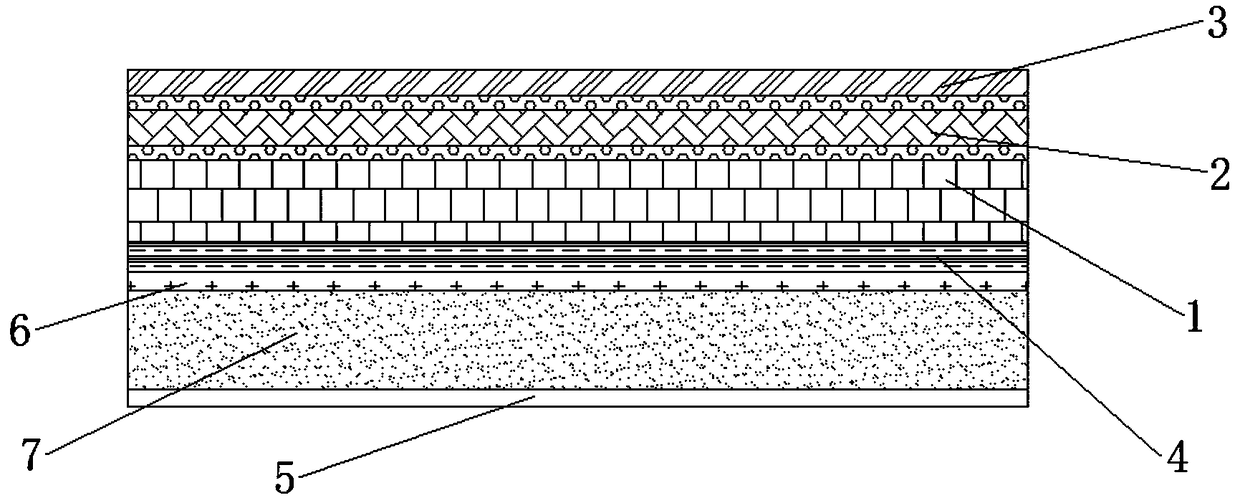

[0037] see figure 1, an odor-absorbing waterproof material, comprising a TPO material waterproof layer, the lower end of the TPO material waterproof layer is sequentially bonded with a reinforcing layer, an anti-corrosion layer, a modified asphalt layer, and a sticking paper, and the upper end of the TPO material waterproof layer is sequentially bonded with Deodorant layer and wear-resistant layer. The deodorant layer is made of two layers of linear low-density polyethylene microporous film and activated carbon non-woven layer. The activated carbon non-woven layer is located between the two layers of linear low-density polyethylene microporous film. Between, the thickness of linear low density polyethylene microporous membrane is 20um, and there are evenly distributed micropores on the microporous membrane, the diameter of the micropores is 1um, and the active carbon content of the activated carbon non-woven layer is 60%, so that the material can absorb The odor gas in the sur...

Embodiment 2

[0045] An odor-absorbing waterproof material, comprising a TPO material waterproof layer, the lower end of the TPO material waterproof layer is sequentially bonded with a reinforcing layer, an anti-corrosion layer, a modified asphalt layer and anti-sticking paper, and the upper end of the TPO material waterproof layer is sequentially bonded with a Odor layer and wear-resistant layer, the deodorization layer is made of two layers of linear low-density polyethylene microporous membrane and activated carbon non-woven fabric layer, and the activated carbon non-woven fabric layer is located between the two layers of linear low-density polyethylene microporous membrane , the thickness of the linear low density polyethylene microporous membrane is 20um, and there are evenly distributed micropores on the microporous membrane. The odor gas in the environment can clean the surrounding air environment and improve the surrounding air quality. The reinforcement layer is composed of epoxy re...

Embodiment 3

[0053] An odor-absorbing waterproof material, comprising a TPO material waterproof layer, the lower end of the TPO material waterproof layer is sequentially bonded with a reinforcing layer, an anti-corrosion layer, a modified asphalt layer and anti-sticking paper, and the upper end of the TPO material waterproof layer is sequentially bonded with a Odor layer and wear-resistant layer, the deodorization layer is made of two layers of linear low-density polyethylene microporous membrane and activated carbon non-woven fabric layer, and the activated carbon non-woven fabric layer is located between the two layers of linear low-density polyethylene microporous membrane , the thickness of the linear low density polyethylene microporous membrane is 20um, and there are evenly distributed micropores on the microporous membrane. The odor gas in the environment can clean the surrounding air environment and improve the surrounding air quality. The reinforcement layer is composed of epoxy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com