Crawler-type multilayer continuous aerobic fermentation tank equipment and technology

An aerobic fermentation, crawler-type technology, applied in organic fertilizer equipment, preparation and application of organic fertilizers, etc., can solve the problems of containing a large number of pathogenic bacteria, large material push resistance, low degree of automation, etc., to maximize environmental benefits and have Conducive to moisture distribution and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

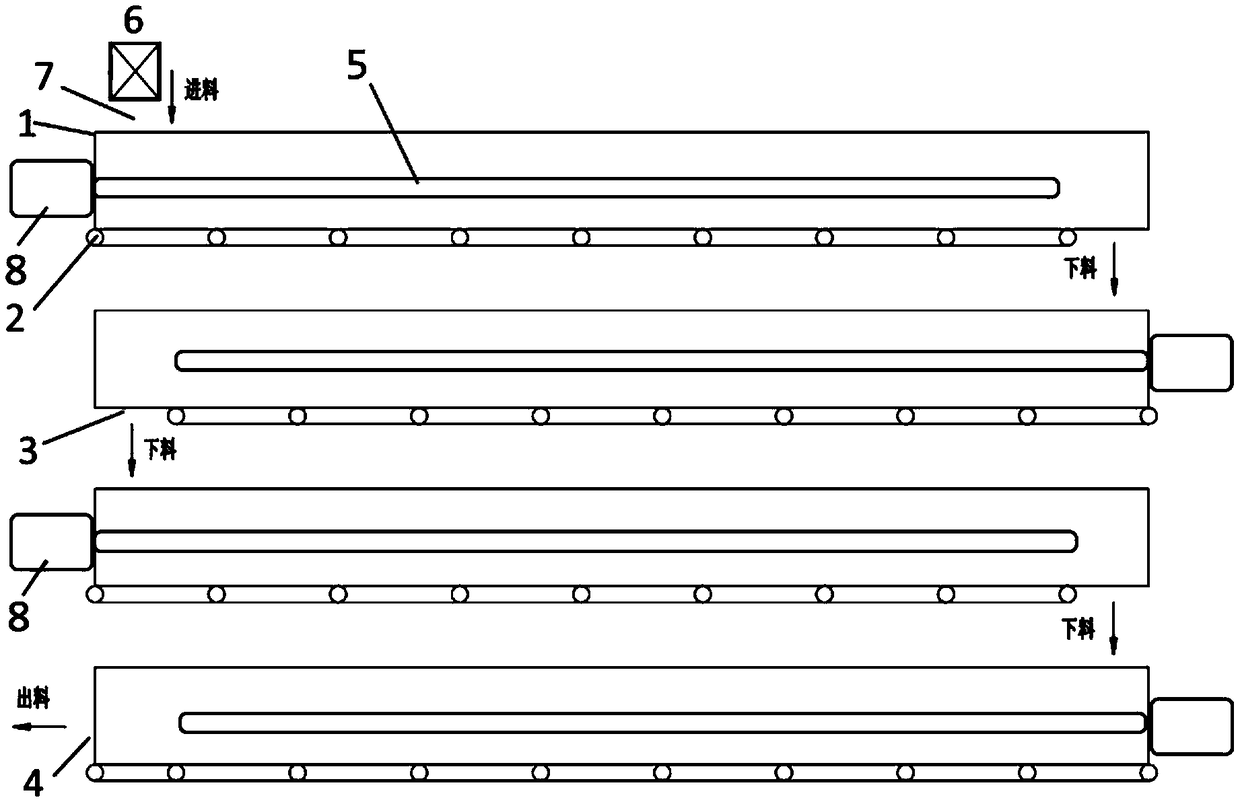

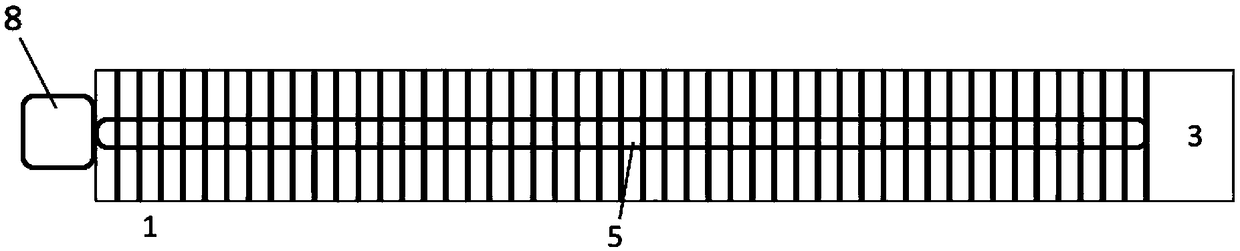

[0016] Such as figure 1 As shown, it is a crawler-type multi-layer continuous aerobic fermentation tank equipment involved in this embodiment, which includes: four crawler-type continuous aerobic fermentation tanks 1 stacked up and down, wherein: the crawler-type continuous aerobic fermentation tanks of adjacent layers The fermenter 1 is arranged in the opposite direction, and the conveying direction is opposite.

[0017] The crawler-type continuous aerobic fermentation tank 1 has a length of 15-25 meters, a width of 1.5 meters and a height of 1.4 meters, and the distance between adjacent layers is 0.8 meters.

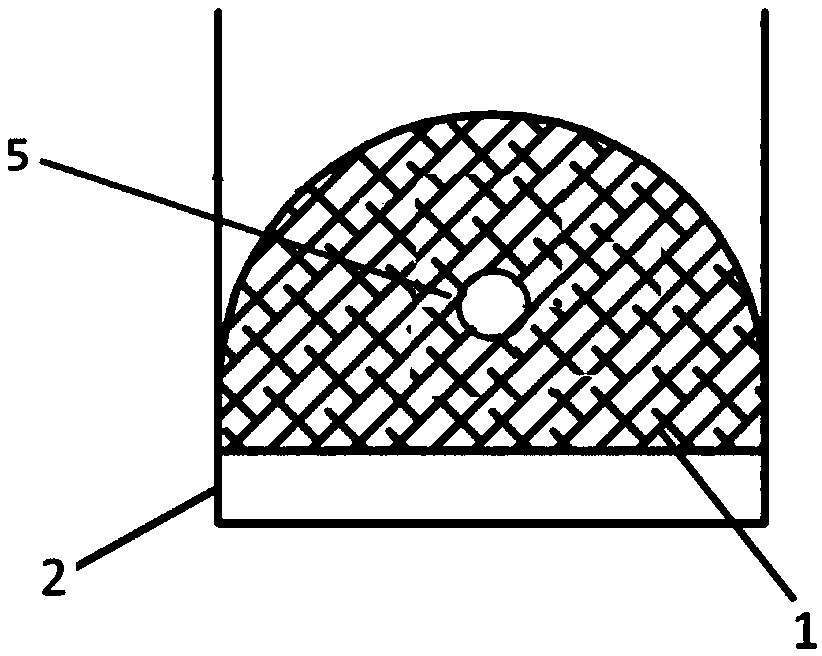

[0018] The bottom of the crawler-type continuous aerobic fermentation tank 1 is provided with a crawler belt conveying mechanism 2 and a feeding port 3, wherein: the crawler belt conveying mechanism 2 is arranged beside the feeding port 3, and the feeding port 3 of the adjacent layer is relatively arranged on the crawler belt Type continuous aerobic fermentation tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com