A kind of high-explosive thermal aluminum-containing explosive and its preparation method

An explosive and high-explosive technology, which is applied in the field of high-explosive heat aluminum-containing explosive and its preparation field, can solve problems such as poor preparation technology of aluminum-containing explosive, and achieve the effect of improving the explosive heat and good preparation technology of the explosive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

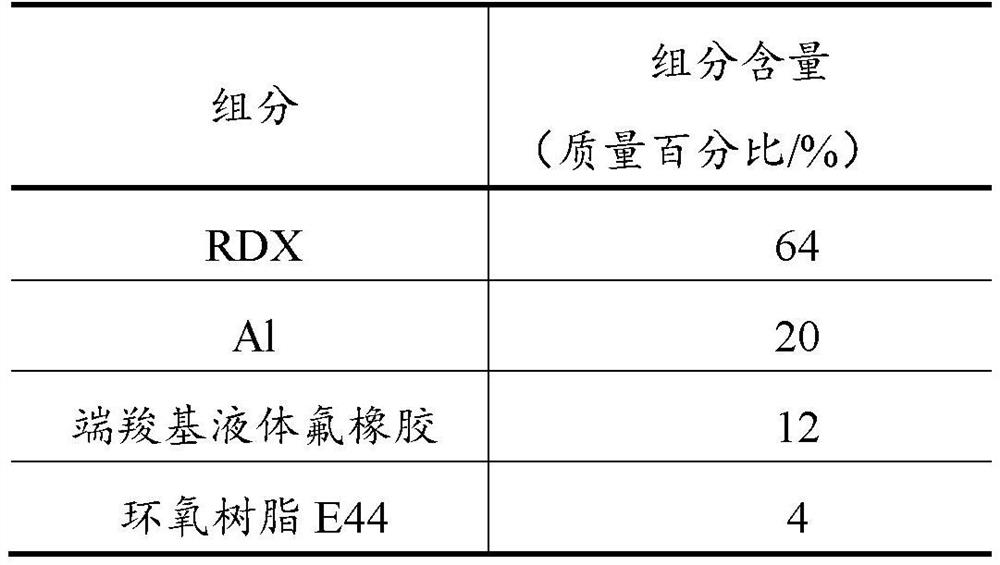

[0023] A high-explosive thermal aluminum-containing explosive, the formula is shown in Table 1.

[0024] The high-explosive thermal aluminium-containing explosive formula of table 1 embodiment 1

[0025]

[0026] The preparation method of above-mentioned high-explosive thermal aluminum-containing explosive comprises the following steps:

[0027] Step (1): take raw materials according to the formula in Table 1;

[0028] Step (2): stirring and dissolving the carboxyl-terminated liquid fluororubber with acetone solvent, the mass ratio of the two is 1:1;

[0029] Step (3): Add Al and RDX respectively into the liquid fluororubber, stir and mix evenly.

[0030] Step (4): Add the curing agent epoxy resin E44 into the mixture and stir evenly.

[0031] Step (5): Put the prepared material into the mold by vacuum casting, remove the acetone solvent and a small amount of air entrained in the slurry, and then put it into a high-temperature oven at 65°C for heating and curing.

[003...

Embodiment 2

[0035] A high-explosive thermal aluminum-containing explosive, the formula is shown in Table 2.

[0036] The high-explosive heat aluminum-containing explosive formula of table 2 embodiment 2

[0037]

[0038] The preparation method of above-mentioned high-explosive thermal aluminum-containing explosive comprises the following steps:

[0039] Step (1): take raw materials according to the formula in Table 2;

[0040] Step (2): stirring and dissolving the hydroxyl-terminated liquid fluororubber with acetone solvent, the mass ratio of the two is 1:1;

[0041] Step (3): Add Al and HMX respectively into the liquid fluororubber, stir and mix evenly.

[0042] Step (4): Add the curing agent HDI trimer into the mixture, stir and mix evenly.

[0043] Step (5): Put the prepared material into the mold by vacuum casting, remove the acetone solvent and a small amount of air entrained in the slurry, and then put it into a high-temperature oven at 65°C for heating and curing.

[0044] T...

Embodiment 3

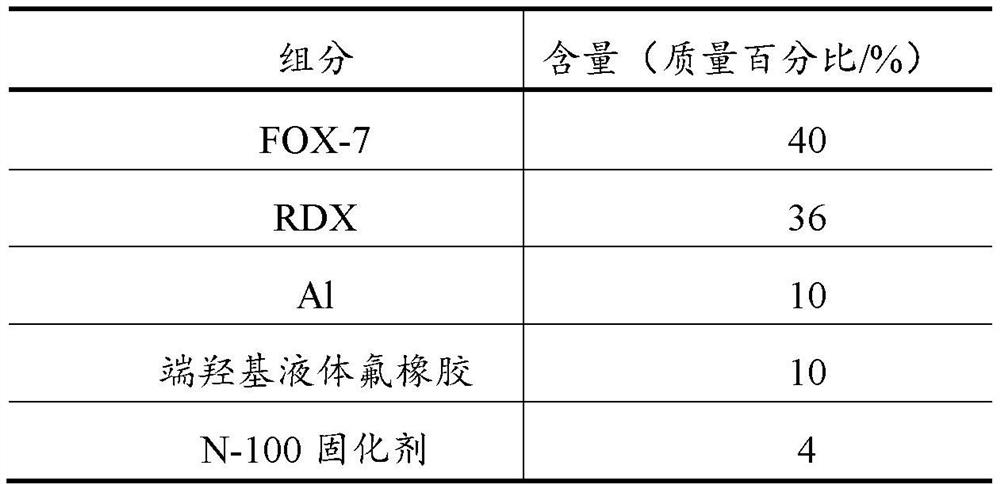

[0047] A high-explosive thermal aluminum-containing explosive, the formula is shown in Table 3.

[0048] The high-explosive heat aluminum-containing explosive formula of table 3 embodiment 3

[0049]

[0050] The preparation method of above-mentioned high-explosive thermal aluminum-containing explosive comprises the following steps:

[0051] Step (1): take raw materials according to the formula in Table 3;

[0052] Step (2): stirring and dissolving the hydroxyl-terminated liquid fluororubber with acetone solvent, the mass ratio of the two is 1:1;

[0053] Step (3): Add Al, FOX-7, and RDX respectively into the liquid fluororubber, stir and mix evenly.

[0054] Step (4): Add curing agent N-100 into the mixture and stir evenly.

[0055] Step (5): Put the prepared material into the mold by vacuum casting, remove the acetone solvent and a small amount of air entrained in the slurry, and then put it into a high-temperature oven at 65°C for heating and curing.

[0056] The pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com