Method for high-temperature continuous acylation in sucralose production

A sucralose, medium and high temperature technology, applied in the chemical industry, can solve the problems of energy consumption, low reaction yield, low reaction temperature, etc., and achieve the effects of improving operating temperature, product purity, and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

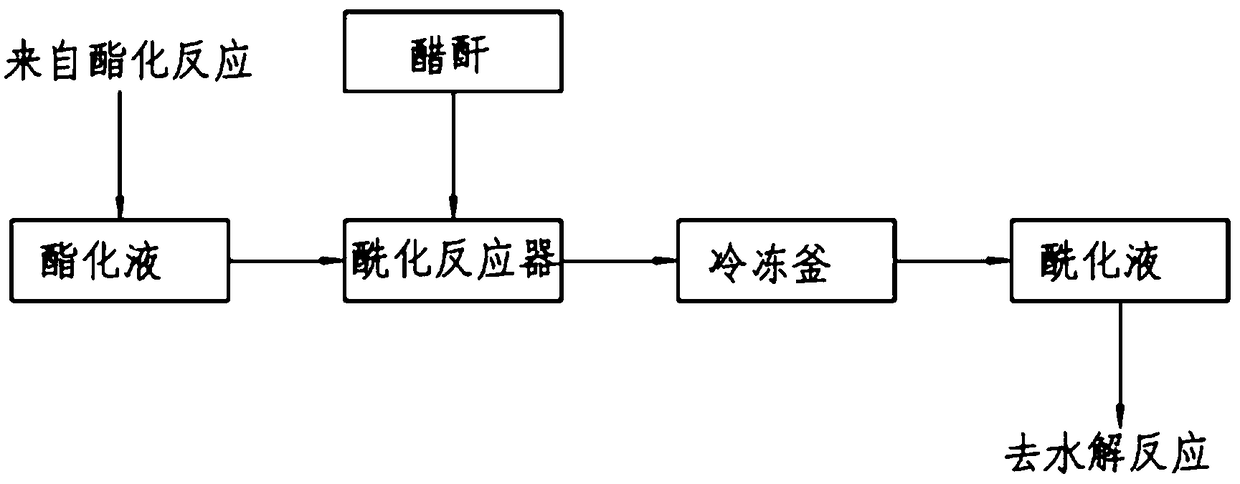

Image

Examples

Embodiment 1

[0014] Pump the esterification solution containing sucrose organotin intermediate (including intermediate: 65wt%, DMF: 35wt%) and acetic anhydride into the acylation reactor at the same time. The temperature of the reactor is about 30°C. The esterification solution and acetic anhydride The mass ratio of the mixture is 10:1, and the acetic anhydride flow rate is adjusted to make the pH value of the reaction mixture reach 4.5, and the acylation reaction can be completed in 0.2s. The material at the outlet of the acylation reactor enters the acylation freezer to cool down at 10-15° C., and is kept warm with chilled water, and the retention time of the heat preservation is 1 hour.

[0015] The acylation reaction liquid is then subjected to hydrolysis reaction, and then cyclohexane is added for extraction and extraction to recover the organic tin acetate produced after the reaction, and the content of sucrose-6-ethyl ester in the acylation reaction liquid is detected, and the reacti...

Embodiment 2

[0018] The esterification solution containing sucrose organotin intermediate: intermediate: 65wt%, DMF: 35wt% esterification solution is pumped into the acylation reactor, pumped into acetic anhydride to adjust the flow rate to make the pH of the reaction mixture to 5, esterification Liquid and acetic anhydride are pumped into the acylation reactor at the same time, the mass ratio of esterification liquid to acetic anhydride is 13:1, the temperature of the reactor is controlled at 10-15°C, and the reaction time is controlled at 0.2s. The material at the outlet of the reactor enters the acylation In the freezer, keep warm with circulating water.

[0019] The acylation reaction liquid is then subjected to hydrolysis reaction, and then cyclohexane is added for extraction and extraction to recover the organic tin acetate produced after the reaction, and the content of sucrose-6-ethyl ester in the acylation reaction liquid is detected, and the reaction yield is ≥98%.

[0020] Cyclo...

Embodiment 3

[0022] The esterification solution containing sucrose organotin intermediate: intermediate: 65wt%, DMF: 35wt% esterification solution is pumped into the acylation reactor, pumped into acetic anhydride to adjust the flow rate to make the pH of the reaction mixture to 5, esterification Liquid and acetic anhydride are pumped into the acylation reactor at the same time, the mass ratio of esterification liquid to acetic anhydride is 15:1, the temperature of the reactor is controlled at 10-15°C, and the reaction time is controlled at 0.2s. The material at the outlet of the reactor enters the acylation In the freezer, keep warm with circulating water.

[0023] The acylation reaction solution is then subjected to hydrolysis reaction, and then cyclohexane is added for extraction and extraction to recover the organic tin acetate produced after the reaction, and the content of sucrose-6-ethyl ester in the acylation reaction solution is detected, and the reaction yield is ≥98%.

[0024] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com