Nanofiber airgel with photothermal conversion, sound insulation and heat insulation and good mechanical recovery and preparation method thereof

A nanofiber, photothermal conversion technology, applied in the direction of cellulose/protein conjugated rayon, melt spinning, conjugated synthetic polymer rayon, etc., can solve the complex, high cost and yield of aerogel process. Small and other problems, to achieve the effect of good heat insulation, good mechanical properties, and expand the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

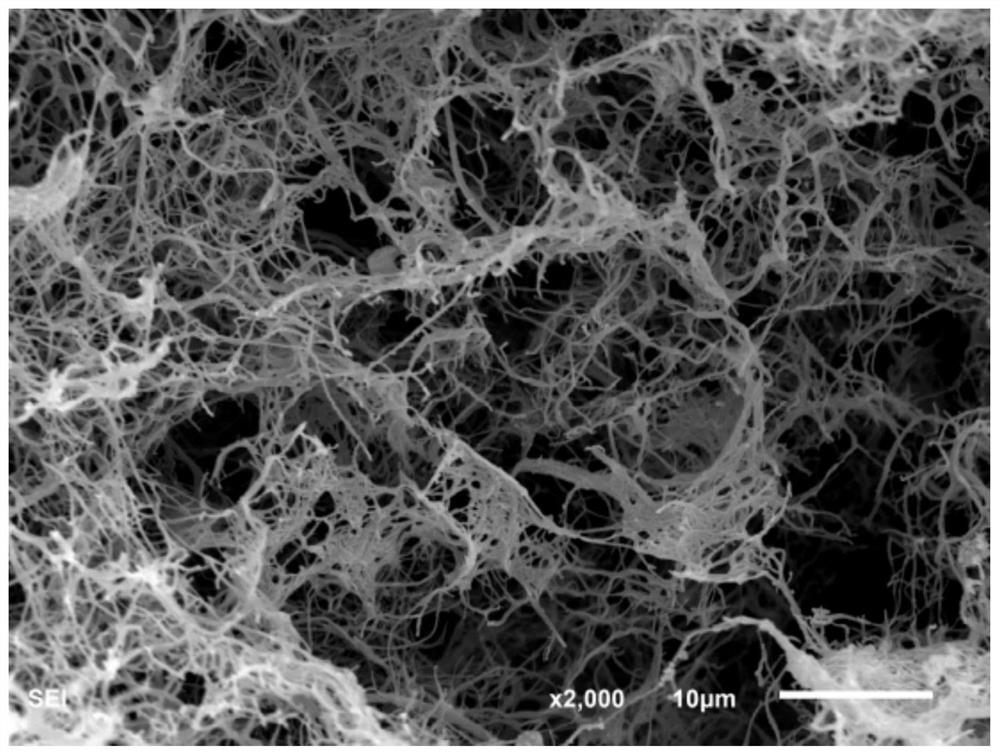

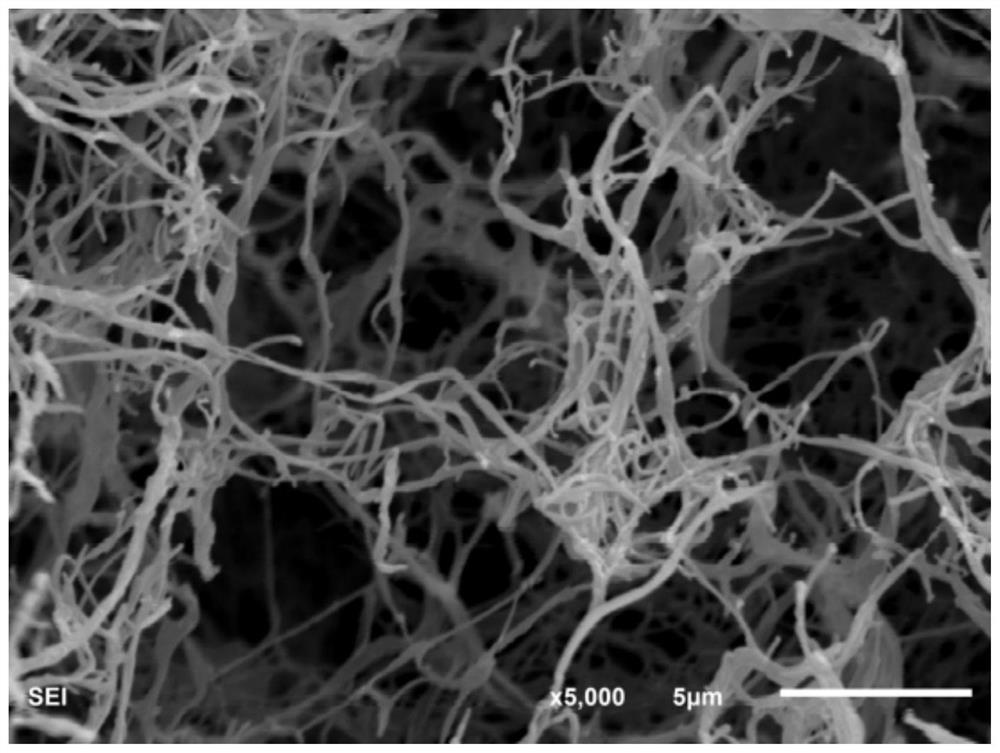

[0043] This embodiment discloses a preparation method of nanofiber airgel with functions of light-to-heat conversion, sound insulation and noise reduction, and heat insulation. The specific process is as follows:

[0044] Weigh 142.56kg of isopropanol and 96.04kg of deionized water, mix them uniformly and heat to 80°C; weigh 99kg of EVOH masterbatch with a vinyl content of 44% and 1kg of nano-ZrC powder; weigh the EVOH masterbatch Dissolve the particles in the heated mixture of isopropanol and water and stir to completely dissolve the EVOH; add nano-ZrC powder to the dissolved EVOH solution and emulsify with an emulsifier, so that the nano-ZrC powder is evenly dispersed in the EVOH solution; The prepared mixed solution is slowly poured into ice water and stirred, so that the EVOH mixed with nano-ZrC powder is precipitated; the separated functional EVOH is dried and pulverized with a pulverizer, and the pulverized EVOH is mixed with 400kg of Cellulose acetate butyrate (CAB) is ...

Embodiment 2

[0048] Weigh 142.56kg of isopropanol and 96.04kg of deionized water, mix them evenly and heat to 80°C; weigh 98kg of EVOH masterbatch with a vinyl content of 44% and 2kg of nano-ZrC powder; weigh the EVOH masterbatch Dissolve the particles in the heated mixture of isopropanol and water and stir to completely dissolve the EVOH; add nano-ZrC powder to the dissolved EVOH solution and emulsify with an emulsifier, so that the nano-ZrC powder is evenly dispersed in the EVOH solution; The prepared mixed solution is slowly poured into ice water and stirred, so that the EVOH mixed with nano-ZrC powder is precipitated; the separated functional EVOH is dried and pulverized with a pulverizer, and the pulverized EVOH is mixed with 400kg of Cellulose acetate butyrate (CAB) is mixed evenly and added to the hopper of the twin-screw extruder, melted and blended, wound and collected into bundles. Among them, the temperature settings of each heating zone of the screw are: zone 1: 160°C; zone 2: ...

Embodiment 3

[0052] Weigh 142.56kg of isopropanol and 96.04kg of deionized water, mix them uniformly and heat to 80°C; weigh 97kg of EVOH masterbatch with a vinyl content of 44% and 3kg of nano-ZrC powder; weigh the EVOH masterbatch Dissolve the particles in the heated mixture of isopropanol and water and stir to completely dissolve the EVOH; add ZrC powder to the dissolved EVOH solution and emulsify it with an emulsifier, so that the nano-ZrC powder is evenly dispersed in the EVOH solution; The prepared mixed solution is slowly poured into ice water and stirred to precipitate the EVOH mixed with nano-ZrC powder; dry the precipitated functional EVOH and pulverize it with a pulverizer, and mix the pulverized EVOH with 400kg of acetic acid After the cellulose butyrate (CAB) is mixed evenly, it is added into the hopper of the twin-screw extruder, melted and blended, wound and collected into bundles. Among them, the temperature settings of each heating zone of the screw are: zone 1: 160°C; zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com