One-step hydrothermal method for preparing ultrathin Fe3O4/CNTs (carbon nanotubes) composite wave-absorbing nanomaterial with high absorbability

A nano-absorbing material and wave-absorbing material technology, which is applied in the field of wave-absorbing, can solve the problems of high density, complexity, and easy-to-corrosion preparation, and achieve the effect of simple process, high reflection loss, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

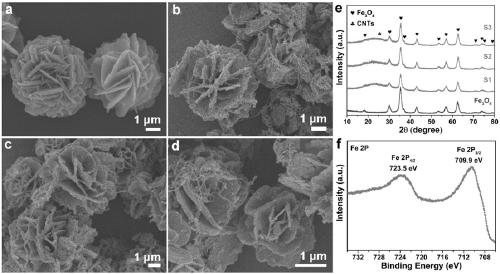

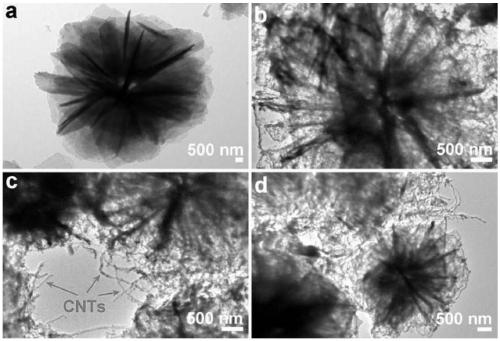

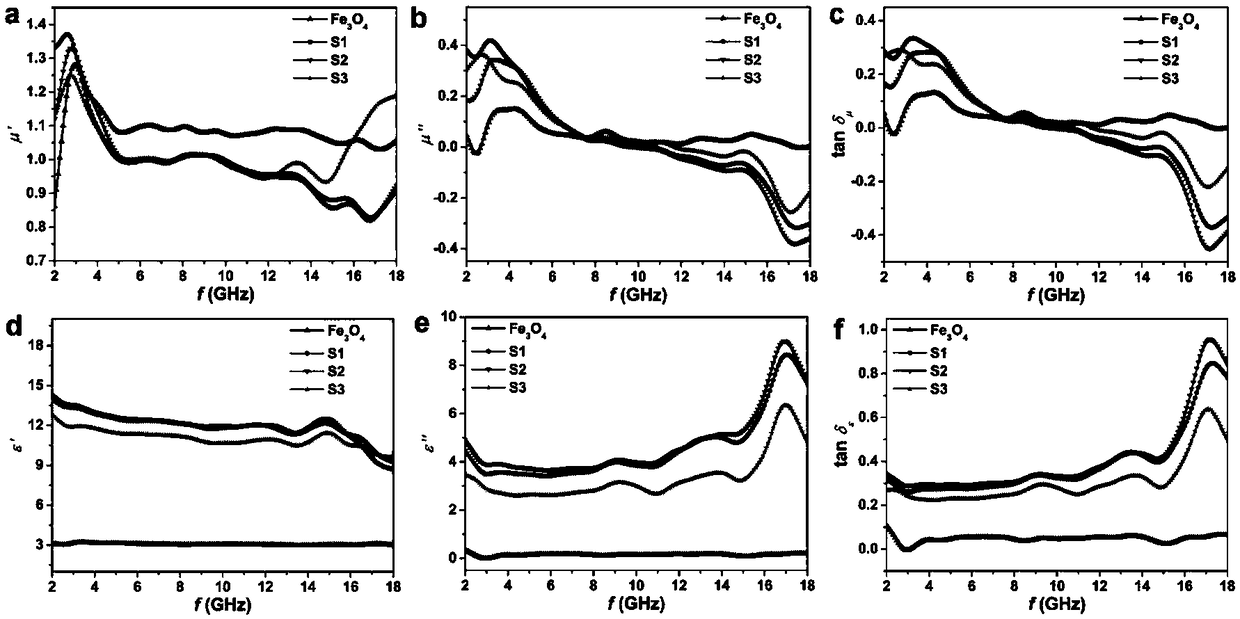

[0019] Ultra-thin and highly absorbent Fe 3 o 4 / CNTs composite nano wave-absorbing material preparation method specific steps are as follows:

[0020] In the first step, 0.4g of ferric chloride hexahydrate was dissolved in 60ml of ethylene glycol, stirred by magnetic force to form a uniform solution, then 0.9g of urea and 2.4g of tetrabutylammonium bromide were added and stirred until dissolved, and then added to the solution 0wt%, 3wt%, 5wt%, and 7wt% of CNTs were added to the mixture, and subjected to magnetic stirring and ultrasonic treatment for 20 min.

[0021] In the second step, the obtained mixed solution was transferred to a 100 ml reaction kettle, and the reaction kettle was placed in a vacuum oven at 180° C. for 1 hour. After the sample was completely cooled to room temperature, the precipitate was collected by centrifuge separation, and washed several times with deionized water and absolute ethanol, and then the obtained product was dried in a vacuum oven.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com