Microbial preparation method of suberogorgin

A microbial and corallic acid technology, applied in the field of microorganisms, can solve the problems of asymmetric synthesis, no report on the preparation of gorgonian acid by microorganisms, and cumbersome steps of gorgonian acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] An embodiment of the microbial preparation method of gorgonian acid of the present invention.

[0043] (1) Strain activation: use an inoculation loop to take an appropriate amount of seeds from the EGF15-0-3 strain storage tube, inoculate into a 100mL triangular conical flask containing 50mL PDA liquid medium, and shake at a constant temperature of 25-28°C. Cultivate in the bed at a speed of 150-170 rpm for 2-3 days to obtain a seed culture solution of EGF15-0-3;

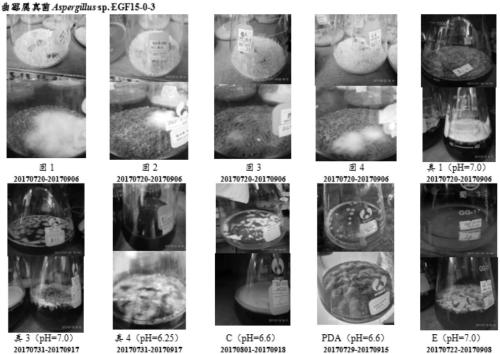

[0044] (2) Strain fermentation: the above-mentioned activated seed culture solution was transferred to different fermentation media in an amount of 1.5%; the fermentation media were 8 kinds of liquid culture media, 4 kinds of solid media and 11 kinds of biotransformation culture 2L for each culture medium, and 2L for each blank culture medium; various cultures are based on static culture at 25-28°C for 48-60 days, observe and record the growth status of the strains during the culture period, liquid and The g...

Embodiment 2

[0063] An embodiment of post-treatment of metabolites in the microbial preparation method of gorgonian acid in the present invention.

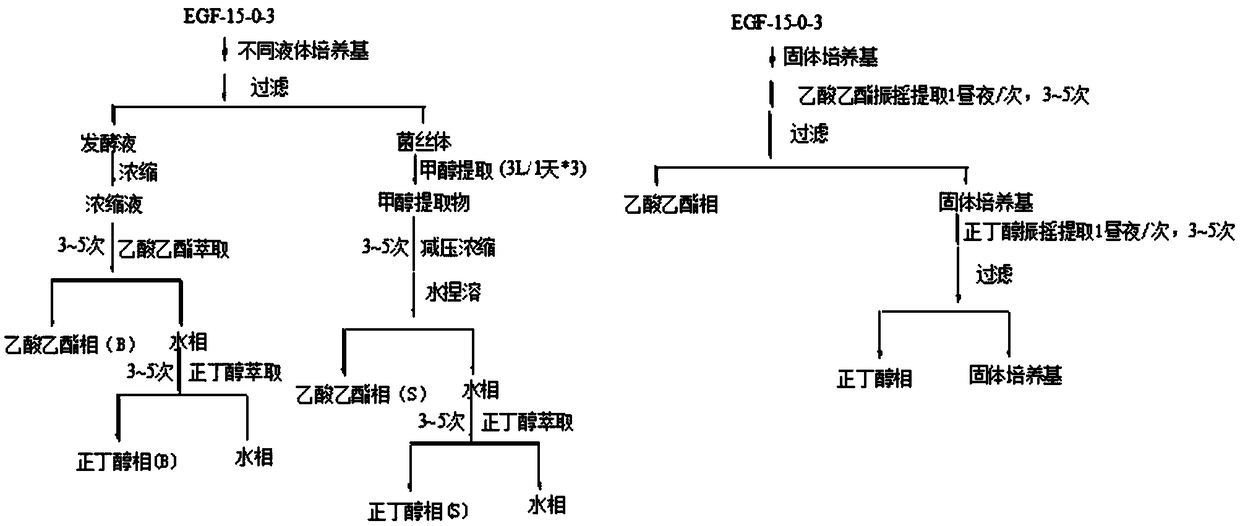

[0064] The flow chart of post-treatment of secondary metabolites in different media is as follows: image 3 shown. After the bacterial strains of each fermentation medium in Example 1 are inactivated, the liquid medium culture solution is filtered with gauze, and the fermentation solution and mycelia are separated; , n-BuOH (n-butanol) extraction three times, the extract obtained is concentrated, and finally the fermented liquid EtOAc, n-BuOH phase extract is obtained; the mycelium is extracted 3 times with methanol (1 time / day), and the methanol is combined The extract was concentrated under reduced pressure to obtain methanol extract, which was dissolved in water and then extracted three times with equal volumes of EtOAc and n-BuOH in the same way to obtain mycelium EtOAc and n-BuOH phase extract. An equal volume of EtOAc was added to the ...

Embodiment 3

[0065] Example 3 Separation and structure identification of gorgonian acid

[0066] 1. Isolation of Gorniconic Acid

[0067] Use an inoculation loop to take an appropriate amount of seed solution from the EGF15-0-3 strain preservation tube, and inoculate it into 50mL PDA medium (potatoes 200g / L, glucose 2.0%, potato juice prepared with old seawater as a solvent, natural pH) In a 100mL Erlenmeyer flask, cultured in a shaker at 28°C at 165r / min for 2 days to obtain a seed culture solution of EGF15-0-3. Draw 1.5mL of the seed solution and add it to a 1000mL Erlenmeyer flask filled with 500mL D medium (potatoes 200g / L, glucose 2.0%, potato juice prepared with aged sea water, natural pH), and culture at 28°C for 60 days , compared with the blank medium to observe whether there is obvious strain growth, stop the fermentation after the growth is completed, and separate and co-ferment 220L of bacterial liquid.

[0068]The fermentation broth is filtered with gauze to obtain two parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com