Flue gas treatment system of boiler

A technology for processing system and boiler flue gas, which is applied in the direction of gas treatment, combustion product treatment, climate sustainability, etc., can solve the problems of huge equipment, limited waste heat recovery effect, equipment corrosion, etc., to reduce the moisture absorption load, Good economic benefits and the effect of increasing the return water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

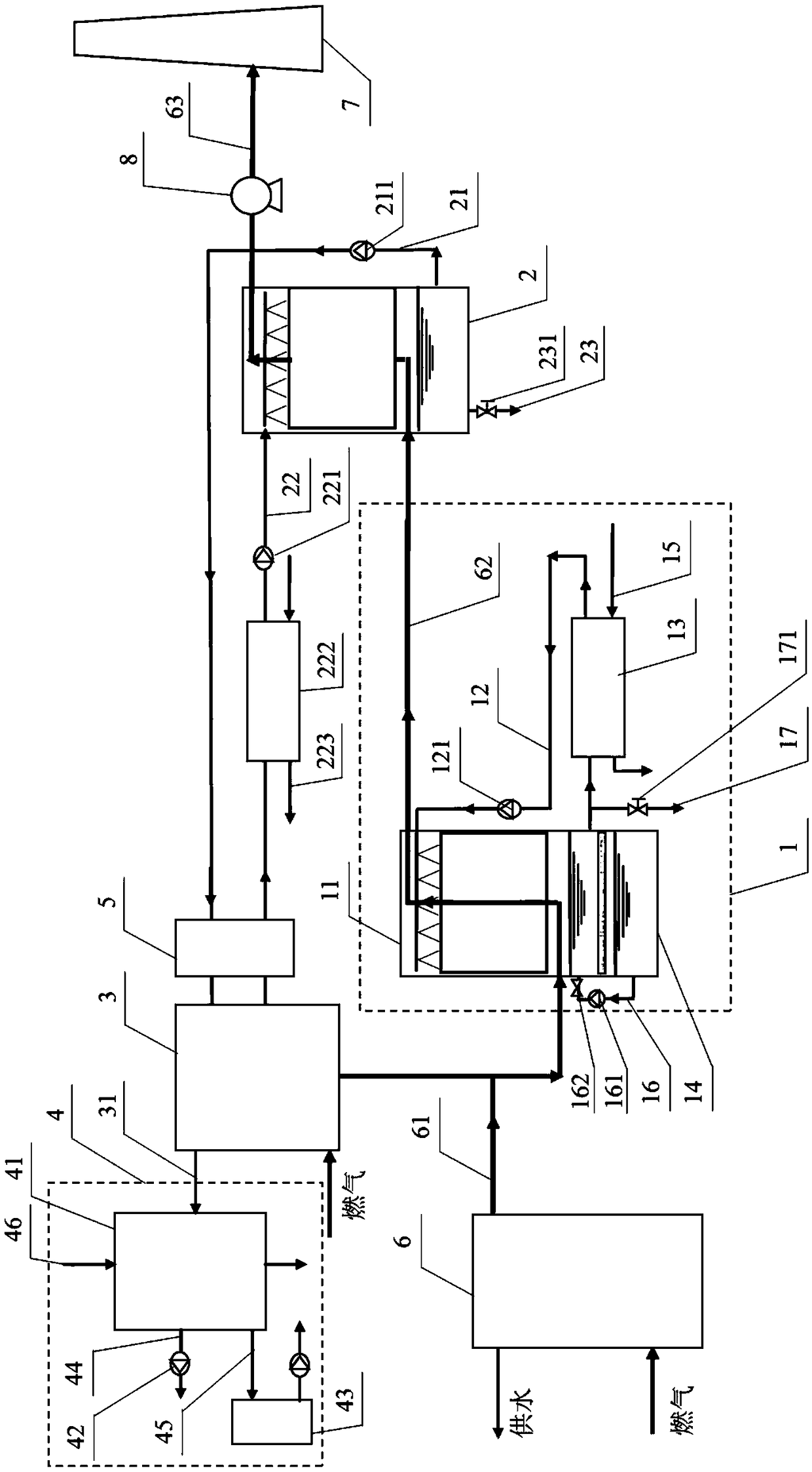

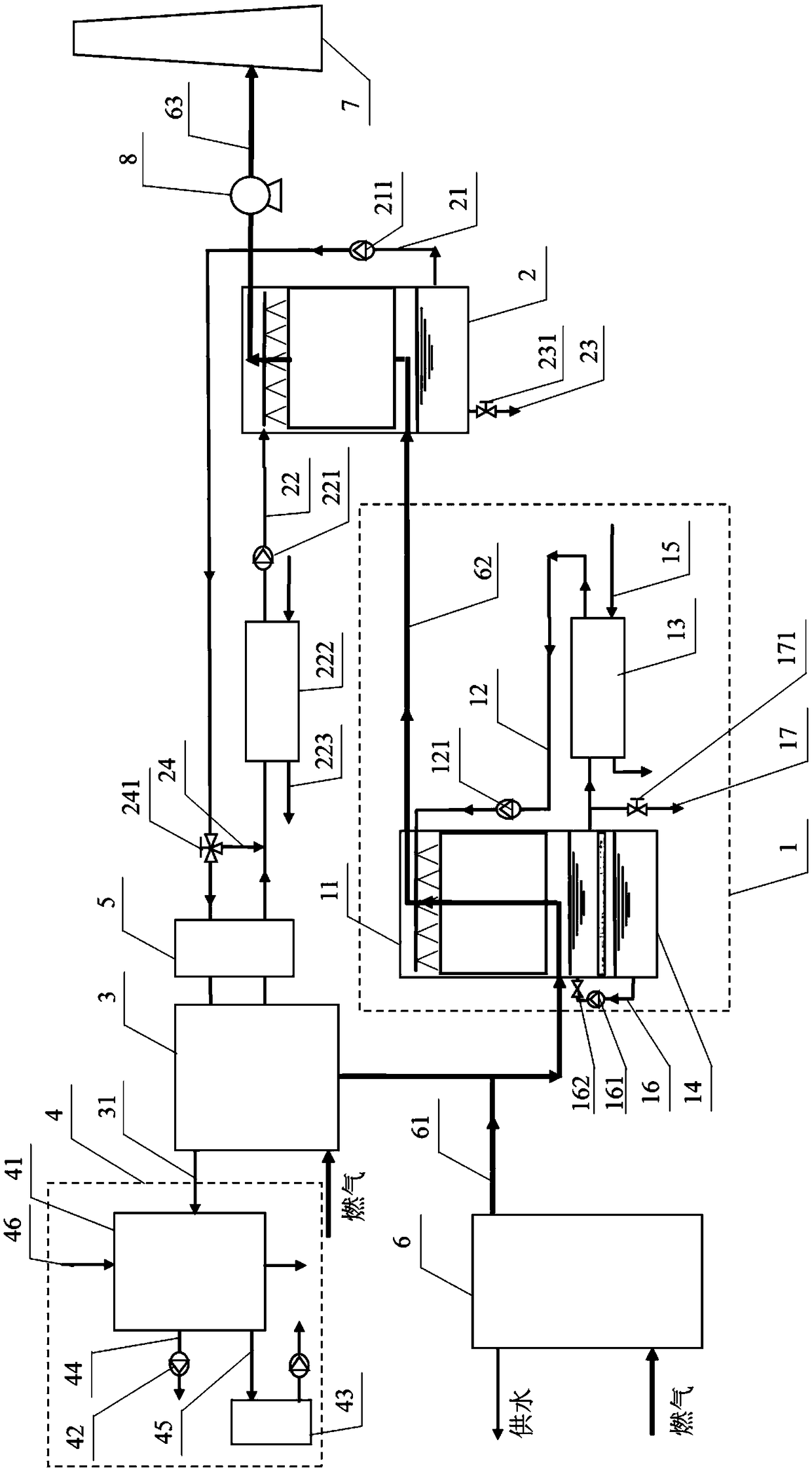

[0062] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0063] likefigure 1 and figure 2 As shown, the present invention provides a boiler flue gas treatment system, wherein the boiler flue gas treatment system includes a flue gas condensing unit 1, an absorber 2, a regenerator 3, a steam condensing unit 4 and a plurality of return water branch pipes, the flue gas The condensing unit 1 communicates with the boiler 6 through the first exhaust pipe 61, the absorber 2 communicates with the flue gas condensation unit 1 through the second exhaust pipe 62, and the absorber 2 communicates with the chimney 7 through the third exhaust pipe 63, and the boiler The flue gas in 6 enters the flue gas condensing unit 1 from the boiler 6 through the first exhaust pipe 61, and in the flue gas cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com