Drop hammer type low-speed impact testbed

A low-velocity impact and test bench technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as poor applicability, insufficient data, and inability to change the temperature environment, so as to improve flexibility and universality, improve Effects on Reliability and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

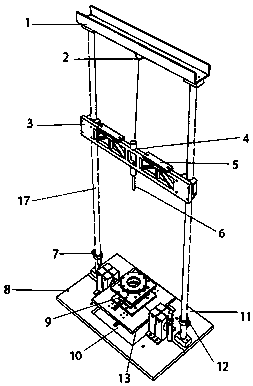

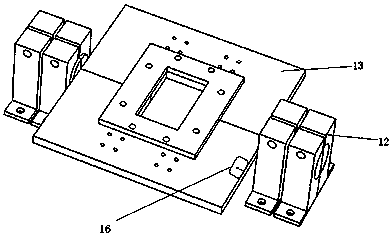

[0034] refer to Figure 1~4 , In an embodiment of the present invention, a drop-weight low-speed impact test bench, 1. Including the main body of the test bench for fixing the specimen, the drop weight assembly, the angle adjustment mechanism and the temperature adjustment mechanism:

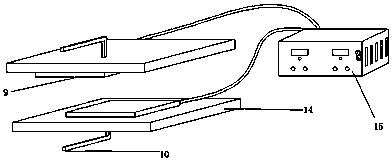

[0035] The test bench body includes a hammer lifting beam 1, a limiter 7, an impact bottom plate 8, a hydraulic oil buffer pressure adjustable cylinder shock absorber 11, multiple detachable splints 13 for various impact hole test pieces, and a vertical rod 17. The test piece splint 13 is clamped on the test bench body, and the test piece splint 13 is hinged on the vertical rod 17 and can rotate with the test bench body; the test piece splint 13 is provided with impact notches of two shapes , which are rectangular holes and circular holes respectively, and the upper and lower impact notches have the same size, which can be applied to various specifications of specimens for impact experiments, b...

Embodiment 2

[0041] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that an accelerometer and a sensor are also provided on the pendant 6, and the accelerometer is installed at the end of the pendant 6, which can The acceleration of the hanging hammer 6 is constantly monitored, and the real-time speed of the hanging hammer is obtained by integrating the time t, and the contact load of the material plate is obtained by using the formula F=ma.

[0042] The working principle of the present invention is: the first step, at the beginning of the test, according to the specifications of the test piece, select the test piece splint 13 that adopts the corresponding impact hole, place the test piece in the center of the bottom splint, and fix the test piece splint with bolts 13 of the upper plate, so that the test piece cannot be displaced, and gently push the test piece by hand to check whether it is clamped;

[0043] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com