Mask plate, wafer, crystal grains and plasma etching and splitting method

A technology of plasma and mask, which is applied in the field of ion etching fragments, can solve the problems of increasing crystal grains, increasing grinding time, and reducing wafer efficiency, and achieves the effects of reducing force, reducing risk, and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

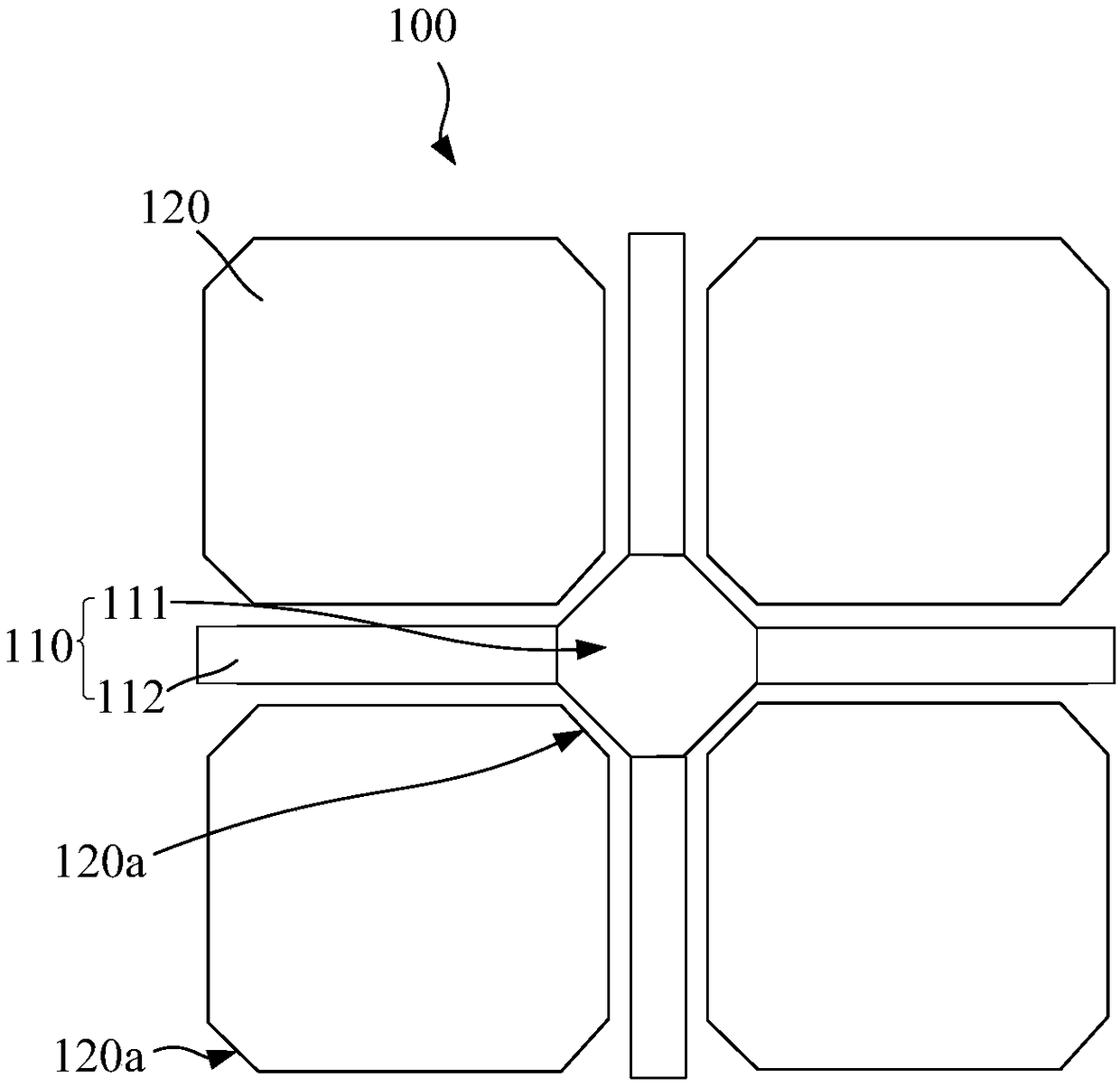

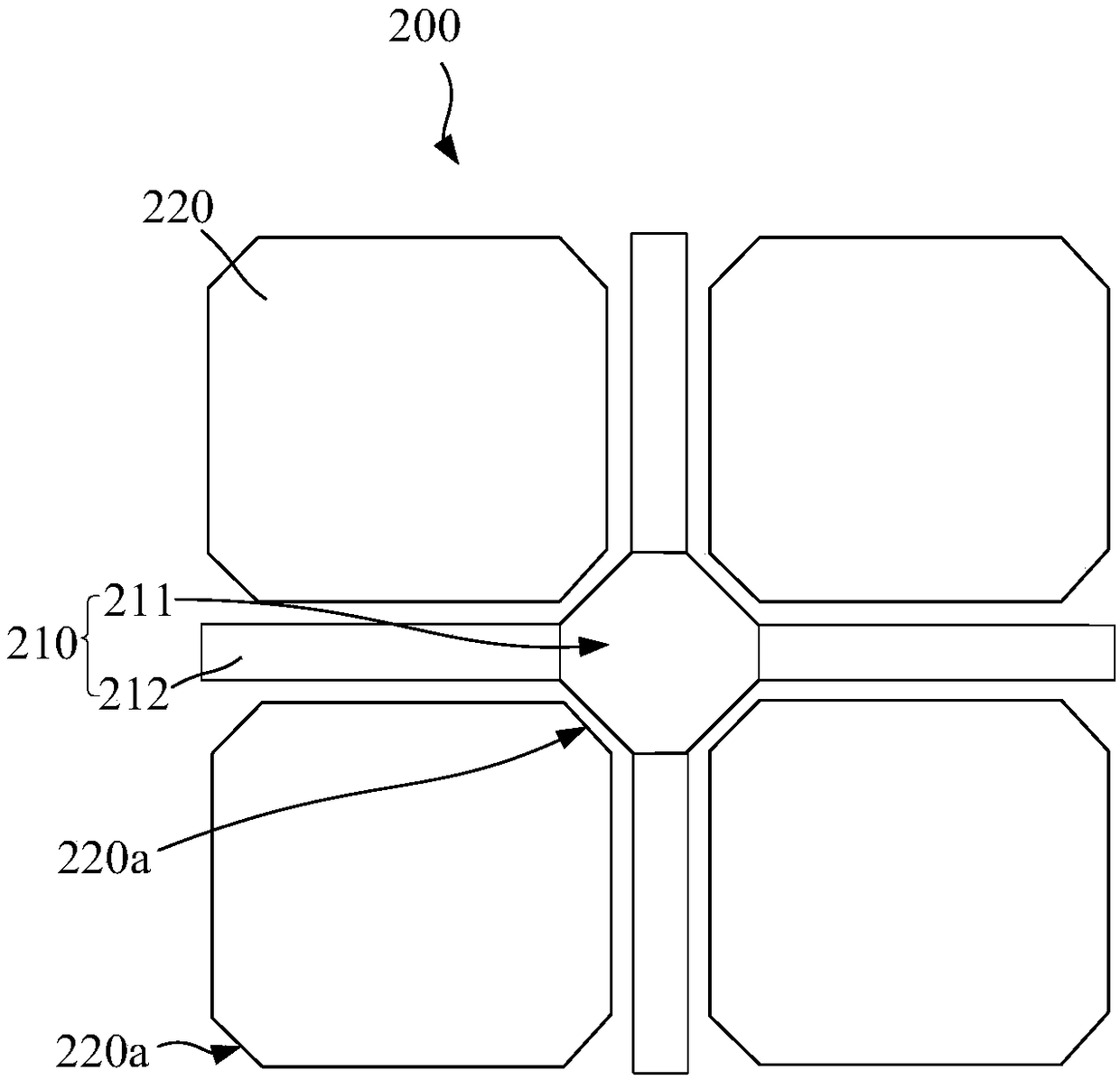

[0042] As described in the background art, in plasma cutting wafers, such as etching before grinding, since the crossing position of the cutting line is the intersection of several cutting lines, the plasma in the non-crossing position converges at the crossing position, As a result, the plasma concentration at the crossing position is much higher than that at the non-crossing position, so that when the substrate is etched, the groove depth at the crossing position is too deep than that at the non-crossing position. During the grinding process, the four corners of most dies on the wafer are the first to wear through. With the continuation of the grinding process, when all the grains are about to be separated, the gap between the grains becomes larger and larger, and there will be mutual extrusion between the grains, so that the grains collide with each other; After the crystal grains are separated, the grains will also collide with each other when taking the chip. The above-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com