Grinding wheel dressing device and method for electrical discharge grinding

A technology for grinding processing and dressing devices, which is applied to the parts of grinding machine tools, abrasive surface adjustment devices, metal processing equipment, etc. It can solve the problems of frequent disassembly and replacement of grinding wheels, shorten the waiting time for downtime, facilitate cleaning, and reduce labor costs. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

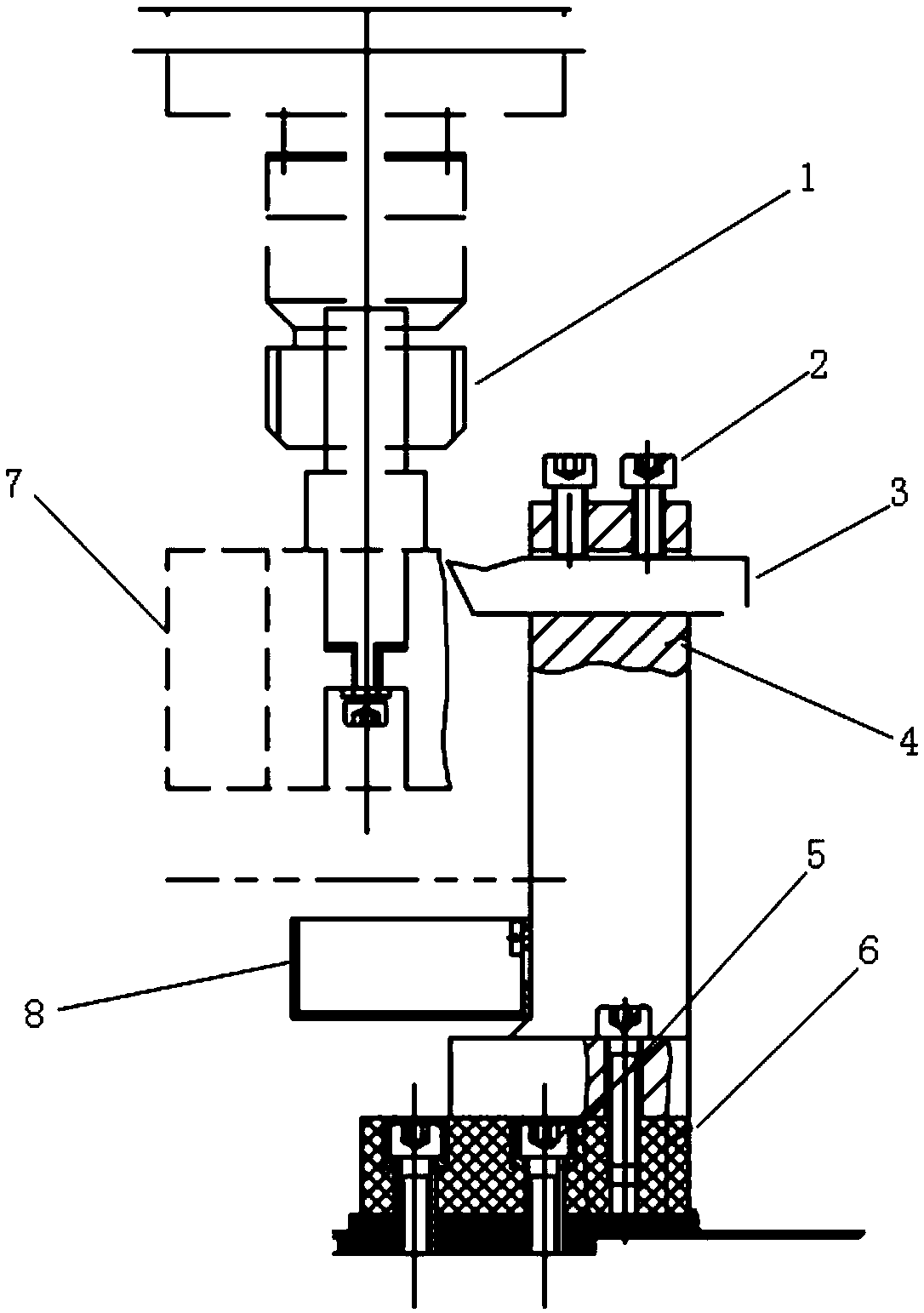

[0048] Such as Figure 5 As shown, the X-axis moving part 11 , the Y-axis moving part 12 and the Z-axis moving part 10 are driven by a screw to finally realize the movement of the main shaft 1 in the three-coordinate system.

[0049] The programmable controller PLC is connected with the servo motor, X-axis motor, Y-axis motor and Z-axis motor; the servo motor is used to control the rotation of the main shaft 1, the X-axis motor is used to control the X-direction displacement of the main shaft 1, and the Y-axis motor is used for Control the Y-direction displacement of the spindle 1, and the Z-axis motor is used to control the Z-direction displacement of the spindle 1;

[0050] The X-axis moving part 11 includes an X-axis moving platform, and the X-axis moving platform is provided with an X-axis guide rail 111, an X-axis screw 112 and an X-axis slider 113, and the X-axis screw 112 is installed above the X-axis guide rail 111, and the X-axis The slider 113 is installed on the X-...

Embodiment 2

[0055] The transmission between the X-axis moving part 11 , the Y-axis moving part 12 and the Z-axis moving part 10 is realized through a guide rail pulley mechanism, and finally the movement of the main shaft 1 in the three-coordinate system is realized. Can refer to Figure 5 ,Will Figure 5 Sliders in are replaced with pulleys.

[0056] The programmable controller PLC is connected with the servo motor, Y-axis motor, Z-axis motor and stepping motor; the servo motor is used to control the rotation of the main shaft 1, the Y-axis motor is used to control the X-direction displacement of the main shaft 1, and the Z-axis motor is used for Control the Y-direction displacement of spindle 1, and the stepper motor is used to control the Z-direction displacement of spindle 1;

[0057] The X-axis moving part 11 includes an X-axis moving platform, and an X-axis guide rail 111 is arranged on the X-axis moving platform;

[0058] The Y-axis moving part 12 includes a Y-axis moving platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com