Method for preparing Fe3O4 powder with controllable form by using local magnetic field change

A form and powder technology, applied in the field of nano-powder preparation and application, can solve the problems of high cost, poor environmental friendliness, complex process, etc., and achieve the effects of using less raw materials, good environmental friendliness, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

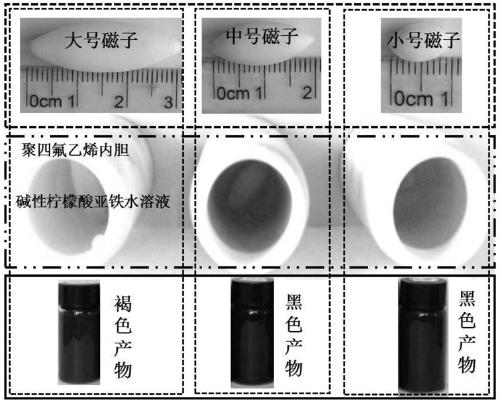

[0019] Example 1: Magnon size versus Fe 3 o 4 The effect of particle assembly

[0020] Preparation of Fe with Controllable Morphology by Using Local Magnetic Field 3 o 4 The steps of powder are as follows:

[0021] 1), divide into three groups of experiments altogether, each group takes by weighing 0.27g ferrous sulfate (FeSO 4 ·7H 2 O) and 1.5g of sodium citrate (Na 3 Cit) is put into the deionized water of 60mL, stirring and dissolving is mixed with ferrous citrate aqueous solution;

[0022] 2), drop an appropriate amount of ammonia water in the prepared ferrous citrate aqueous solution to adjust its pH value to 10;

[0023] 3), transfer each group of prepared alkaline ferrous citrate aqueous solution into a polytetrafluoroethylene reaction kettle, add 1cm small magnets, 2cm medium magnets and 3cm large magnets respectively, and seal;

[0024] 4) Put the reaction kettle into an oven at 180°C for 24 hours, take out the precipitate and wash and dry it to obtain differe...

Embodiment 2

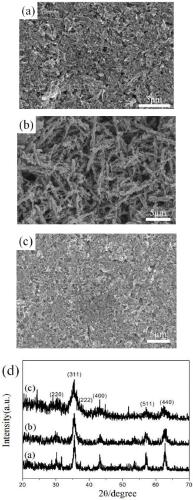

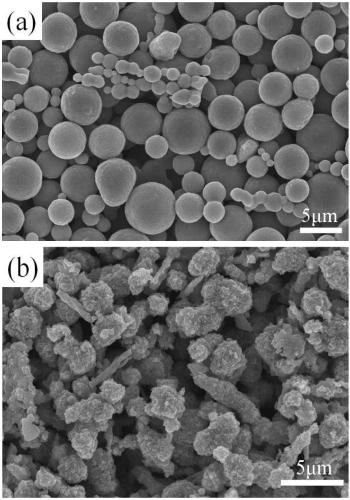

[0030] Example 2: Reaction time to Fe 3 o 4 The effect of particle assembly

[0031] It was found that the reaction time has a great influence on the final Fe 3 o 4 The morphology of the powder also has a great influence. When other reaction conditions remain unchanged, Fe can be effectively regulated by changing the reaction time. 3 o 4Powder form. The alkaline ferrous citrate aqueous solution that is prepared with embodiment 1 is equally divided into two parts, carries out hydrothermal reaction after all adding medium model magneton, and setting reaction time is respectively 12h and 48h, and the form of the product that obtains is as follows image 3 shown. Depend on image 3 a It can be seen that when the reaction is 12h, the product is spherical Fe 3 o 4 Mainly, a small number of small-sized particles aggregated into straight particle chains. image 3 b is the Fe obtained from the reaction for 48h 3 o 4 From the SEM image of the product, it can be seen that th...

Embodiment 3

[0032] Embodiment 3: Different forms of Fe 3 o 4 Study on Magnetic Properties of Powder

[0033] Utilize two kinds of forms Fe prepared in embodiment 2 3 o 4 The product was tested for its magnetic properties at room temperature, and the results were as follows Figure 4 As shown, as the reaction time is different, the obtained Fe 3 o 4 The hysteresis loops of the powder all present S-type. When the external field is scanned from -15000Oe to 15000Oe, the Fe prepared after 12h 3 o 4 Nanoparticles ( Figure 4 The hysteresis curve of a) does not see obvious hysteresis, indicating that the obtained Fe 3 o 4 Smaller particles exhibit superparamagnetic phenomena. And the Fe obtained after 48h 3 o 4 particle chain ( Figure 4 b) The saturation magnetization (M s ) is significantly higher than Fe 3 o 4 nanoparticles. Experiments have shown that different forms of Fe 3 o 4 The magnetic properties of powders at room temperature are very different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com