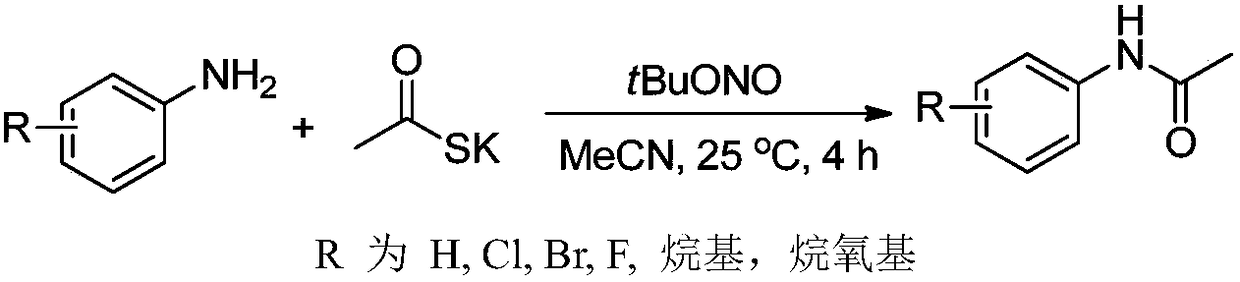

Method for synthesizing acetanilide derivatives

A technology of aniline derivatives and synthesis methods, applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as no literature reports, and achieve easy operation, cheap and easy to obtain raw materials, stable and stable. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

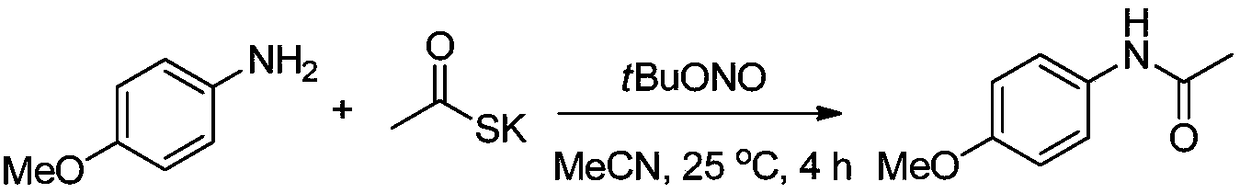

[0014] Embodiment 1: the synthesis of 4-methoxyacetanilide

[0015]

[0016] Add 2mL of acetonitrile, 36.9mg of p-methoxyaniline, 68.4mg of potassium thioacetate, and 6.2mg of tert-butyl nitrite into a 25mL reaction tube, and react with magnetic stirring at 25°C for 4 hours. After the reaction is finished, extract with ethyl acetate, combine the organic phases, evaporate most of the solvents under reduced pressure, use petroleum ether and ethyl acetate as eluent with a composition of 5:1, and conduct column chromatography to separate the remaining mixed solution. After purification, the desired product was obtained as a light yellow solid, 44.6 mg, with a yield of 90%.

[0017] Its NMR data are as follows:

[0018] 1 H NMR (300MHz, CDCl 3 ) δ = 8.24 (s, 1H), 7.39 (d, J = 8.9Hz, 2H), 6.81 (d, J = 8.9Hz, 2H), 3.76 (s, 3H), 2.10 (s, 3H).

Embodiment 2

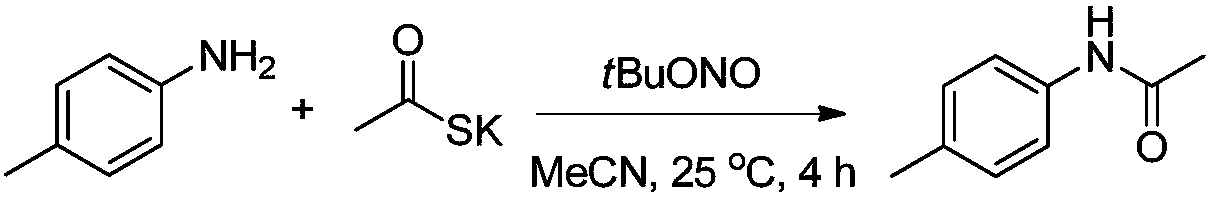

[0019] Embodiment 2: the synthesis of 4-methylacetanilide

[0020]

[0021] Add 2 mL of acetonitrile, 32.1 mg of p-methylaniline, 68.4 mg of potassium thioacetate, and 6.2 mg of tert-butyl nitrite into a 25 mL reaction tube, and react with magnetic stirring at 25° C. for 4 hours. After the reaction is completed, extract with ethyl acetate, combine the organic phases, evaporate most of the solvents under reduced pressure, use petroleum ether and ethyl acetate as eluent with a composition combination of 10:1, and perform column chromatography on the remaining mixed solution After separation and purification, the desired product was obtained as a light yellow solid, 35.8 mg, with a yield of 80%.

[0022] Its NMR data are as follows:

[0023] 1 H NMR (300MHz, CDCl 3 ) δ = 8.10 (s, 1H), 7.39 (d, J = 7.8Hz, 2H), 7.10 (d, J = 7.5Hz, 2H), 2.31 (s, 3H), 2.13 (s, 3H).

Embodiment 3

[0024] Example 3: Synthesis of 4-fluoroacetanilide

[0025]

[0026] Add 2 mL of acetonitrile, 33.3 mg of p-fluoroaniline, 68.4 mg of potassium thioacetate, and 6.2 mg of tert-butyl nitrite into a 25 mL reaction tube, and react with magnetic stirring at 25° C. for 4 hours. After the reaction is completed, extract with ethyl acetate, combine the organic phases, evaporate most of the solvents under reduced pressure, use petroleum ether and ethyl acetate as eluent with a composition combination of 10:1, and perform column chromatography on the remaining mixed solution After separation and purification, the desired product was obtained as a light yellow solid, 30.3 mg, with a yield of 66%.

[0027] Its NMR data are as follows:

[0028] 1 H NMR (300MHz, CDCl 3 ) δ = 7.90 (s, 1H), 7.48-7.43 (m, 2H), 7.02-6.96 (m, 2H), 2.15 (s, 3H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com