A kind of high-performance modified emulsified asphalt and its preparation method

An emulsified asphalt, high-performance technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of insufficient high-temperature performance and low-temperature performance of modified emulsified asphalt, achieve high mechanical strength and anti-stripping performance, promote improvement, Good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

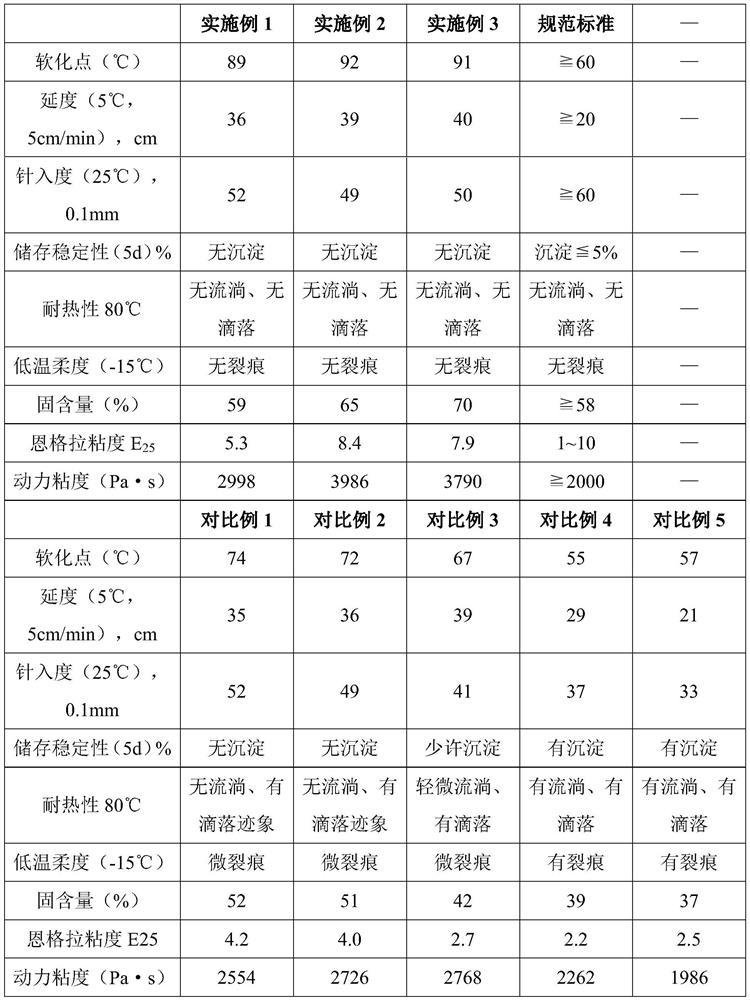

Examples

Embodiment 1

[0036] This example provides a high-performance modified emulsified asphalt, which is made of the following raw materials: 58 parts of base asphalt, 1.4 parts of modifier, 0.7 parts of adhesion promoting resin LTH, 0.2 parts of auxiliary agent, coupling 0.1 part of emulsifier, 0.2 to 2.5 parts of compound emulsifier, 0.6 part of stabilizer, 0.1 part of thickener, and acid liquid as the balance, and the sum of parts by weight of raw materials is 100 parts.

[0037] in:

[0038] The modifier, in parts by weight, is made of the following raw materials: 12 parts of isocyanate, 57 parts of n-butyl borate, 6 parts of polyvinyl acetal, and 25 parts of barium sulfide.

[0039] The auxiliary agent is made of the following raw materials in parts by weight: 60 parts of black stone mud and 40 parts of sepiolite powder.

[0040] Composite emulsifier, in parts by weight, is made of the following raw materials: cetyltrimethylammonium bromide is 45 parts, cetyl polyethylene glycol is 25 part...

Embodiment 2

[0057] This example provides a high-performance modified emulsified asphalt, which is made of the following raw materials: 60 parts of base asphalt, 2.0 parts of modifier, 0.9 parts of adhesion promoting resin LTH, 0.2 parts of auxiliary agent, coupling The compound emulsifier is 0.1 part, the compound emulsifier is 2.2 parts, the stabilizer is 1.0 part, the thickener is 0.2 part, the balance is an acid solution, and the weight parts of raw materials are 100 parts.

[0058] Wherein: modifying agent is identical with embodiment 1. Auxiliary agent is identical with embodiment 1. Composite emulsifier is identical with embodiment 1. Acid solution is identical with embodiment 1. The base asphalt is the same as in Example 1. Coupling agent is identical with embodiment 1. Stabilizer is identical with embodiment 1.

[0059] The preparation method of the high-performance modified emulsified asphalt of this example is basically the same as that of Example 1.

Embodiment 3

[0061] This example provides a high-performance modified emulsified asphalt, which is made of the following raw materials: 62 parts of base asphalt, 2.0 parts of modifier, 0.5 part of adhesion promoting resin LTH, 0.2 part of auxiliary agent, coupling The compound emulsifier is 0.1 part, the compound emulsifier is 2.0 parts, the stabilizer is 1.4 parts, the thickener is 0.2 part, and the balance is acid liquid, and the weight parts of raw materials are 100 parts.

[0062] Wherein: modifying agent is identical with embodiment 1. Auxiliary agent is identical with embodiment 1. Composite emulsifier is identical with embodiment 1. Acid solution is identical with embodiment 1. The base asphalt is the same as in Example 1. Coupling agent is identical with embodiment 1. Stabilizer is identical with embodiment 1.

[0063] The preparation method of the high-performance modified emulsified asphalt of this example is basically the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com