A post-production processing method and system for a hollow fiber membrane

A fiber membrane and hollow technology, which is applied in the field of post-treatment methods and systems for the preparation of hollow fiber membranes, can solve the problems of difficult waste liquid treatment, difficult control of VOC emissions, and large amount of extraction agent, and achieve high equipment sealing and safety. Good application prospects and the effect of reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

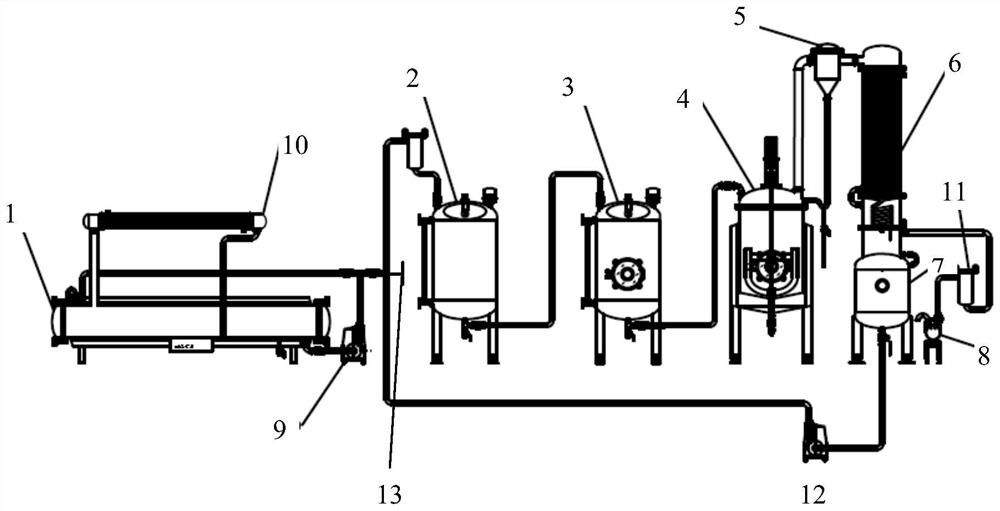

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] The hollow fiber membrane production post-treatment system according to the present invention comprises the following devices:

[0033] The extraction device comprises an extraction tank, the extraction tank is provided with a heating component, and the extraction tank is provided with a porous silk storage tank for placing membrane filaments; the membrane filaments placed in the silk storage tank are mixed with the extraction agent in the extraction tank contacting, the extractant extracts the membrane filaments to obtain the extracted membrane filaments and an extract containing a diluent and an extractant;

[0034] The buffer device includes a settling tank, the extract is precipitated in the settling tank, part of the diluent is precipitated in the form of solid, and the solid-liquid is separated to obtain a solid-phase diluent and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com