Method for extracting high-purity scandium oxide from titanium dioxide waste acid and Bayer-process red mud by virtue of high-temperature acid leaching

A technology of titanium dioxide waste acid and scandium oxide, which is applied in the direction of improving process efficiency, can solve problems such as inability to perform long-term operation, and achieve the effect of reducing the cost of scandium extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

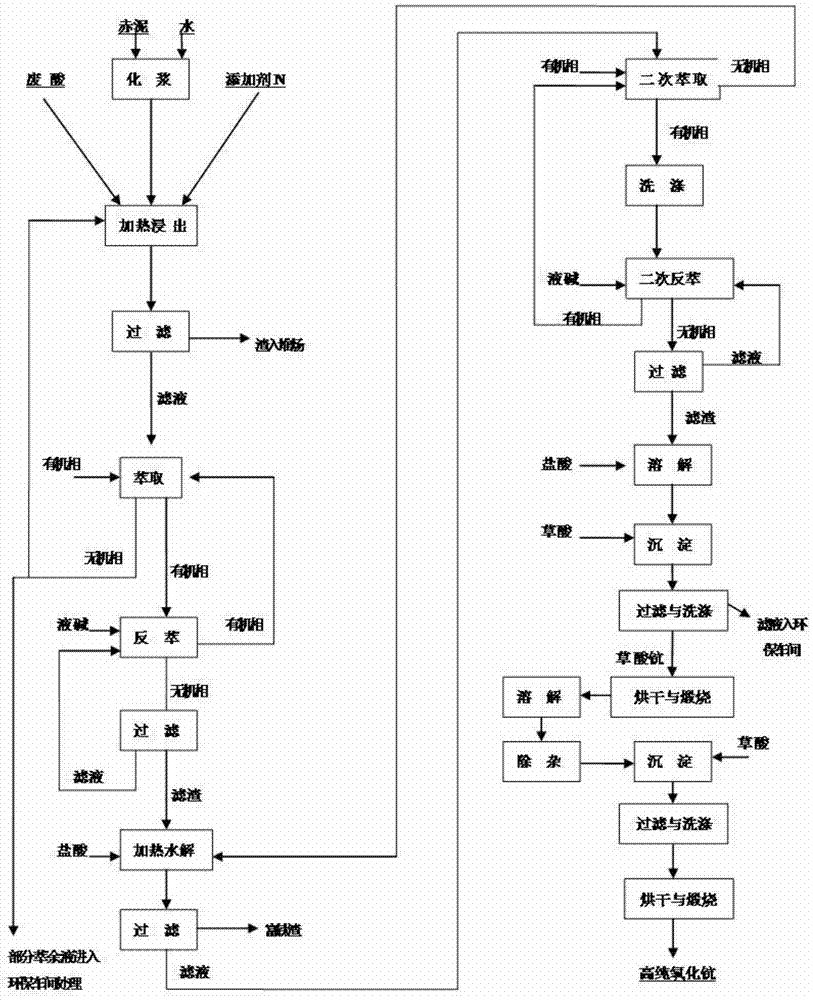

Method used

Image

Examples

Embodiment 1

[0032] at 1m 3 Add 200L mixing water into the reaction tank, start mechanical stirring and gradually add 100kg of powdery Bayer process red mud, continue stirring for 1 hour after adding, then heat up, add acetic acid steam when the material liquid reaches 85°C, and stir for a period of time Finally, add 300 liters of titanium white waste acid at a rate of 5 liters per minute, continue to stir and react for 50 minutes, then cool, and filter when the temperature of the feed liquid is lower than 80°C. After the filter residue is fully washed, it is sent to the residue yard for stacking, and the filtrate is sent to the scandium extraction process. The filtrate containing scandium is extracted and back-extracted. After the stripped residue is dissolved, it is hydrolyzed to remove titanium at 100°C for 2 hours. ℃, adding oxalic acid for precipitation, adding water to the precipitate and then calcining at 850 ℃ to obtain scandium trioxide with a purity of 93.6%. Dissolve scandium ...

Embodiment 2

[0034] at 1m 3 Add 250L mixing water into the reaction tank, start mechanical stirring and gradually add 100kg of powdery Bayer process red mud, continue stirring for 1 hour after adding, then heat up, add additive N when the feed liquid reaches 90°C, and stir for a period of time Finally, add 300 liters of titanium white waste acid at a rate of 6 liters per minute, continue to stir and react for 50 minutes, then cool, and filter when the temperature of the feed liquid is lower than 80°C. After the filter residue is fully washed, it is sent to the residue yard for stacking, and the filtrate is sent to the scandium extraction process. The filtrate containing scandium is extracted and back-extracted. After the stripped residue is dissolved, it is hydrolyzed to remove titanium at 102°C for 2 hours. ℃, add oxalic acid for precipitation, add water to the precipitate and then calcinate at 850 ℃ to obtain scandium trioxide with a purity of 94.3%. Dissolve scandium trioxide with a p...

Embodiment 3

[0036] at 1m 3Add 250L of sizing water into the reaction tank, start the mechanical stirring and gradually add 100kg of powdery Bayer process red mud, continue to stir for 1 hour after adding, then heat up, add additive N when the feed liquid reaches 90 ° C, and stir for a period of time After that, 320 liters of titanium dioxide waste acid was added at a rate of 5.5 liters / minute, and the reaction was continued for 55 minutes with stirring, and then cooled. When the temperature of the feed liquid was lower than 80°C, filtration was performed. The filter residue is fully washed and then sent to the slag yard for stacking, and the filtrate is sent to the scandium extraction process. The scandium-containing filtrate was extracted and back-extracted. After the back-extraction residue was dissolved, the titanium was removed by water at 102 °C for 2 hours. After filtration, the filtrate was subjected to secondary extraction, washed to remove impurities, and then back-extracted. ℃ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com