Graphene concrete and preparation method thereof

A graphene and concrete technology, applied in the field of concrete, can solve the problems of complicated preparation process, insufficient mechanical properties, difficult large-scale preparation, etc., and achieve good stability, improve physical properties, and improve time-dependent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

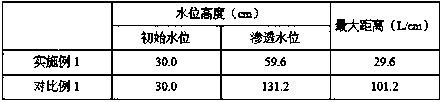

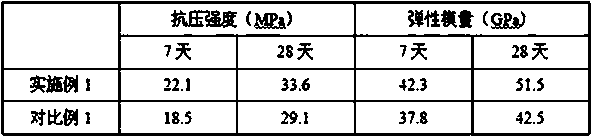

Embodiment 1

[0038] A kind of graphene concrete, its preparation process is as follows:

[0039] S1. prepare the graphene aqueous dispersion liquid that concentration is 0.6g / L.

[0040] After mixing 2.6028 kg of graphite flakes and 0.5206 kg of surfactant sodium cholate with 208 kg of water, they were exfoliated using a high-shear mixer at 5000 rpm for 2 hours. After the stripping was completed, the obtained suspension was decanted to obtain a graphene dispersion with a concentration of 0.6 g / L.

[0041] S2. Add 365 kg of cement, 730 kg of silica sand, 1095 kg of gravel, and 208 kg of graphene aqueous dispersion in the forced mixer, and stir for 10 minutes to obtain graphene concrete slurry. The cement is 42.5R ordinary Portland cement. Silica sand is made by mixing quartz sand in three particle size ranges of (800~400) μm, (400~200) μm and (200~100) μm at a mass ratio of 1:0.286:0.114. Crushed stones include two kinds of crushed stone particles of 5-10 mm and 10-16 mm; the mass fracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com