Glass fiber reinforced PC/ABS alloy with high gloss, permanent antistatic property and high dimensional stability and preparation method thereof

A dimensional stability and antistatic technology, which is applied in the field of glass fiber reinforced PC/ABS alloy and its preparation, can solve the problems that the improvement of dimensional stability is not helpful, the influence of material strength and heat resistance, and the improvement effect are limited, so as to reduce the Mold shrinkage, good stability, and the effect of avoiding warping problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

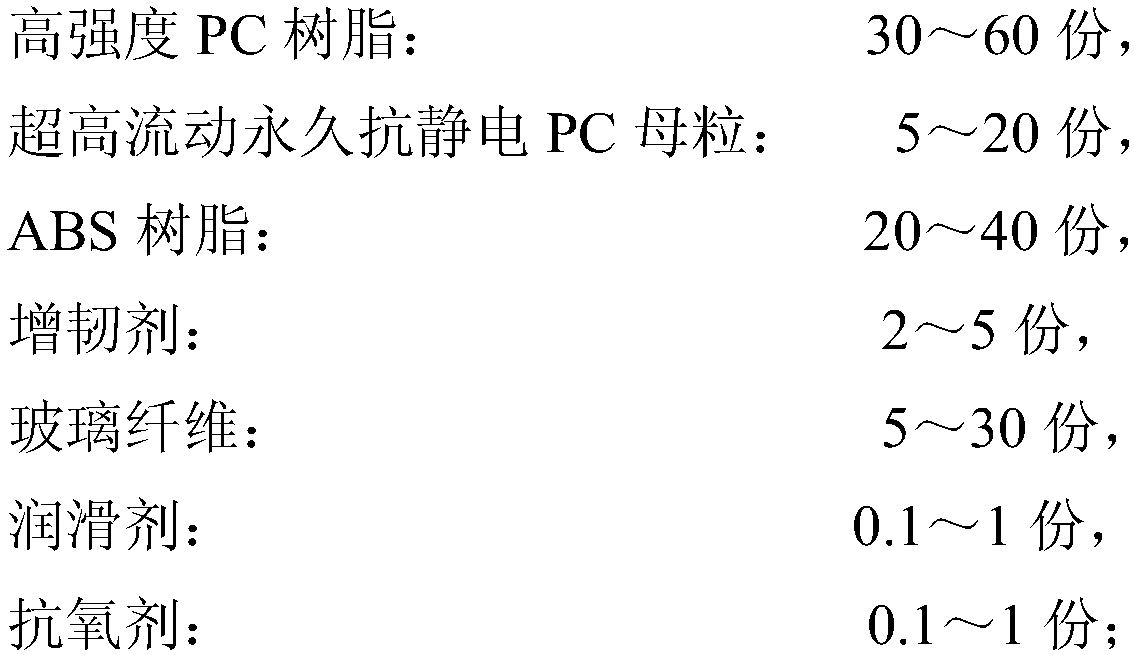

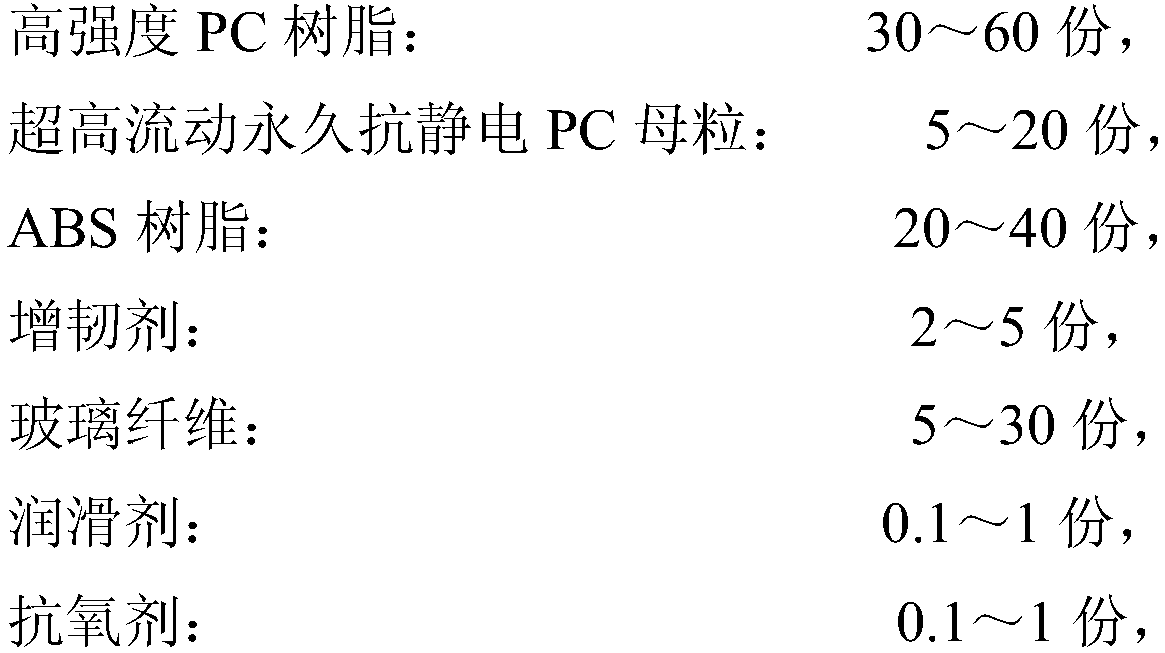

Method used

Image

Examples

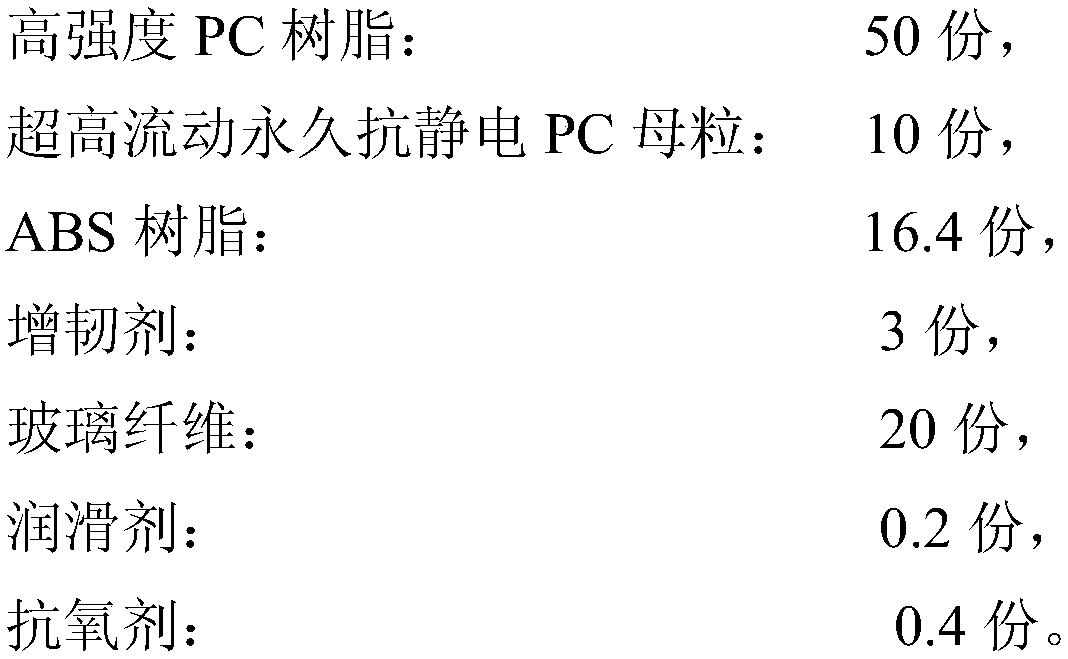

Embodiment 1-5

[0069] Components and proportioning of table 2 embodiment 1-5

[0070]

[0071] Preparation:

[0072] S1. Prepare the raw materials according to the weight ratios in Table 1 and Table 2, put them into the premixer to mix the raw materials evenly, and heat them to 60°C and keep them warm for 15 minutes to obtain the premix;

[0073] S2. Add the premixed material obtained in step S1 into a twin-screw extruder, extrude and pelletize to obtain a PC / ABS composite material, wherein the barrel speed of the twin-screw extruder is 15-35rpm, and the barrel temperature is 220 -270°C;

[0074] S3. The PC / ABS composite material prepared in step S2 is injected into a finished product. The injection molding temperature is 220-270°C, and the mold temperature is 60-100°C.

Embodiment 6

[0075] Embodiment 6: Evaluation of implementation effect

[0076] With the sample that above-mentioned comparative example 1-6 and embodiment 1-5 obtain, product performance test method is as follows:

[0077] Melt index: according to ISO 1133, tested under 5kg load at 260°C;

[0078] Bending strength: According to DIN EN ISO 178, the test speed is 2mm / min;

[0079] Notched impact strength: according to DIN EN ISO 179-1, temperature 23°C;

[0080] Linear expansion coefficient: According to GB / T 1036, the test temperature is -30℃~80℃, and the heating rate is 10℃ / min;

[0081] Mold shrinkage rate: ASTM D955, the size of the test sample is 100*150*3mm, after injection molding, the sample needs to be kept at 23°C and 50% RH for 24 hours, and then the size test is carried out;

[0082] Antistatic performance: According to PV3977, apply a voltage of 70KV to the material for 15s; then test the residual voltage of the sample after 120s;

[0083] Gloss: According to ASTM D2457, rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com