Low-foam organic pigment color paste used for internal dyeing of decorative raw paper and preparation method thereof

A technology of organic pigments and colorants, applied in fiber raw material processing, paper, papermaking, etc., can solve problems such as foam, and achieve the effect of simplified operation process, good low foam effect and good rheological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

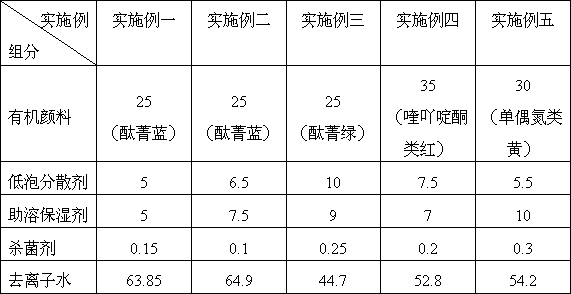

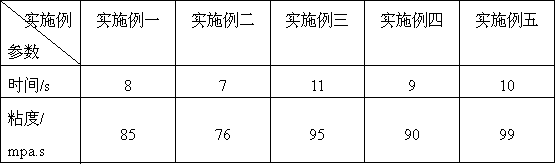

[0022] The formula of the embodiment of the invention is referring to Table 1;

[0023] Table 1 (unit: parts by weight)

[0024]

[0025] In each embodiment, ethylene glycol was used as the solubilizing and moisturizing agent; the wetting and dispersing agent was sodium naphthalene sulfonate; the bactericide was a mixture of commercially available isothiazolinone and benzisothiazolinone.

[0026] For organic pigments, phthalocyanine blue is used in embodiment 1 and embodiment 2; phthalocyanine green is used in embodiment 3; quinacridone red is used in embodiment 4; monoazo flavonoid is used in embodiment 5.

[0027] According to the formula in Table 1, prepare described low-foaming organic pigment color paste, comprise the following steps successively:

[0028] (1) Weigh the solubilizing moisturizer, low-foaming dispersant and deionized water, and put them into the container;

[0029] (2) Add the organic pigment into the mixed solution obtained in step (1), disperse at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com