Dealcoholization type double-component silica gel and preparation method thereof

A two-component, silicone gel technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the limitations of product applications, adhesion, durability, sealing, storage Insufficient stability, deep curing, etc., to achieve the effect of simple operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

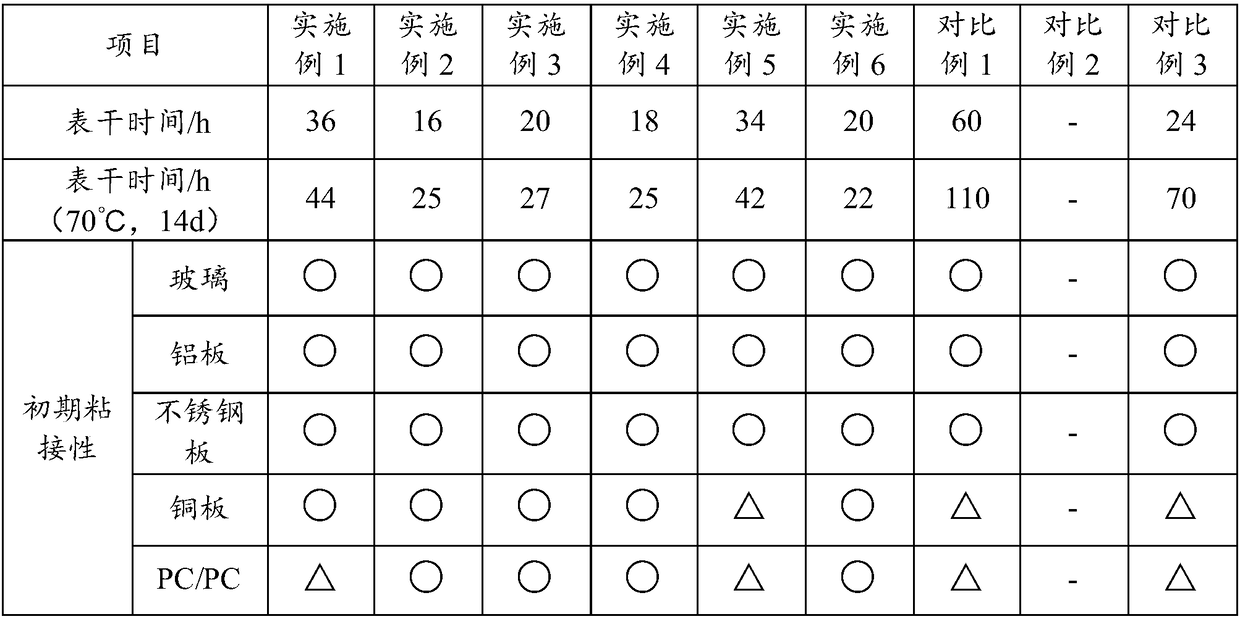

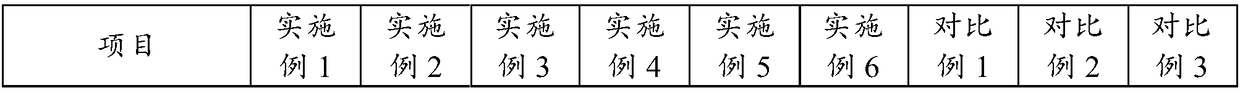

Examples

preparation example Construction

[0088] The present invention also provides a method for preparing the dealcoholized two-component silica gel described in the above technical solution, comprising the following steps:

[0089] a) Mix polydimethylsiloxane, hardness modifier, crosslinking agent and tackifier uniformly to obtain component A;

[0090] b) Mix component B with component A obtained in step a) to obtain dealcoholized two-component silica gel.

[0091] In the present invention, polydimethylsiloxane, hardness regulator, crosslinking agent and tackifier are firstly mixed uniformly to obtain component A. In the present invention, the polydimethylsiloxane, hardness regulator, crosslinking agent and tackifier are the same as those described in the above technical solution, and will not be repeated here.

[0092] The present invention has no special limitation on the mixing method, and the technical solution of manual stirring or mechanical stirring well known to those skilled in the art can be used. The p...

Embodiment 1

[0100] (1) A component: set the kinematic viscosity to 2000mm 2 / s of α, ω-dihydroxy polydimethylsiloxane 100 parts by weight, methyltrimethoxysilane 1.17 parts by weight and tackifier (by molar ratio of 1:2:1 aminopropyltrimethoxy Silane, γ-glycidyl ether oxypropyltrimethoxysilane and isocyanatopropyltrimethoxysilane were mixed and reacted at 50°C for 45h) 0.01 parts by weight and stirred until uniform to obtain dealcoholized two-component silicon A component of the gel.

[0101] (2) B component: use n-butyl titanate as the B component of the dealcoholized two-component silicone gel.

[0102] (3) Inject the above components A and B into a 100mL plastic cup at a mass ratio of 60:0.09 and mix evenly to obtain a dealcoholized two-component silicone gel.

Embodiment 2

[0104] (1) A component: set the kinematic viscosity to 2000mm 2 95 parts by weight of α,ω-dihydroxypolydimethylsiloxane / s and a kinematic viscosity of 300mm 2 / s of α, ω-dihydroxy polydimethylsiloxane 5 parts by weight, 1.0 parts by weight of 1,6-bis(trimethoxysilyl) hexane and tackifier (by molar ratio of 1:2: 1 aminopropyltrimethoxysilane, γ-glycidyl etheroxypropyltrimethoxysilane and isocyanatopropyltrimethoxysilane were mixed and then reacted at 50°C for 45h) 0.01 parts by weight were stirred until uniform, The A component of the dealcoholized two-component silicone gel was obtained.

[0105] (2) B component: use n-butyl titanate as the B component of the dealcoholized two-component silicone gel.

[0106] (3) Inject the above components A and B into a 100mL plastic cup at a mass ratio of 60:0.09 and mix evenly to obtain a dealcoholized two-component silicone gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com