Production method of aluminum alloy sheet plate for welding

A production method and aluminum alloy technology, which is applied in the production field of aluminum alloy plates, can solve problems such as poor welding performance and edge cracking of aluminum alloys, and achieve the effects of improving welding performance, refining grains, and solving desoldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

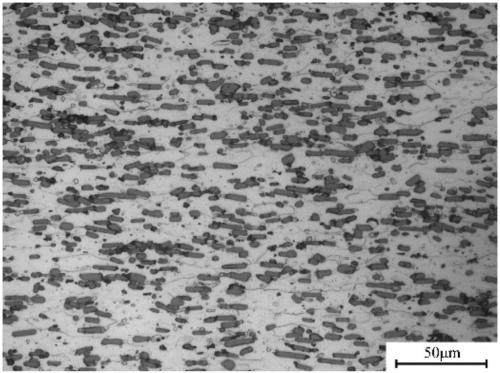

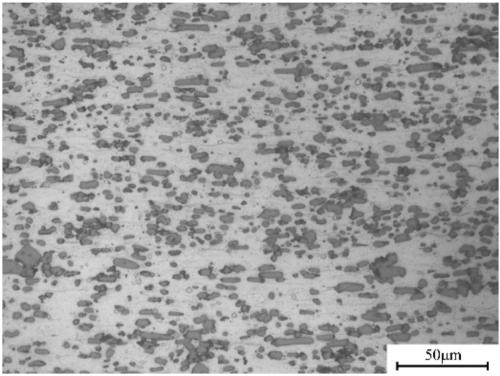

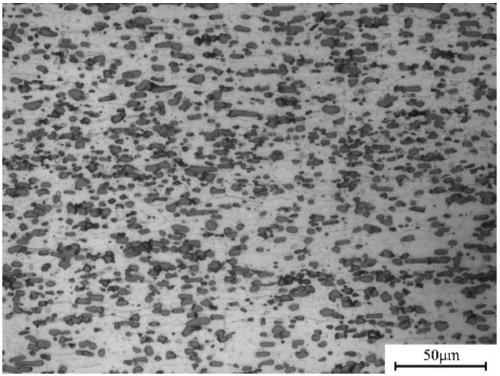

Image

Examples

specific Embodiment approach 1

[0030] Specific implementation mode one: the production method of the aluminum alloy sheet for welding in this embodiment is carried out according to the following steps:

[0031] 1. Si: 11.5-12% by weight, Mn: 0.05-0.1%, Zn: 0.1-0.15%, Ti: 0.01-0.03%, and the balance is Al to weigh aluminum-silicon master alloy, aluminum-manganese master alloy, Aluminum-zinc master alloy, aluminum-titanium master alloy and metal aluminum are used as smelting raw materials, and the smelting raw materials are prepared into aluminum alloy solution;

[0032] 2. Add a sodium salt modifier to the aluminum alloy solution obtained in step 1, and perform melting and casting to obtain an aluminum alloy ingot;

[0033] The sodium salt modificator consists of 74-76% NaC and the rest NaC by mass fraction 3 AlF 6 mixed;

[0034] 3. Milling the aluminum alloy ingot;

[0035] 4. Heating step 3: milling the aluminum alloy ingot after plane treatment, and then transferring it to a hot rolling mill for hot ...

specific Embodiment approach 2

[0044] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the melting temperature in the preparation process of the aluminum alloy solution in Step 1 is 680-720°C. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0045] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the aluminum alloy solution described in step 2 adopts a semi-continuous casting method, the casting temperature is 680-720°C, and the casting speed is 55-60mm / min, the casting cooling water pressure is 0.008~0.15MPa, and the cooling water temperature is 20~26°C. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com