Plasma melting furnace with continuous overflow slag discharge function and application thereof

A plasma and melting furnace technology, applied in the direction of incinerators, combustion methods, lighting and heating equipment, etc., can solve problems such as patent publications that have not yet been found, achieve high-efficiency and rapid melting, high thermal efficiency, and overcome the effect of not sealing the furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0037] Structures not described in detail in the present invention can be understood as conventional structures in the art.

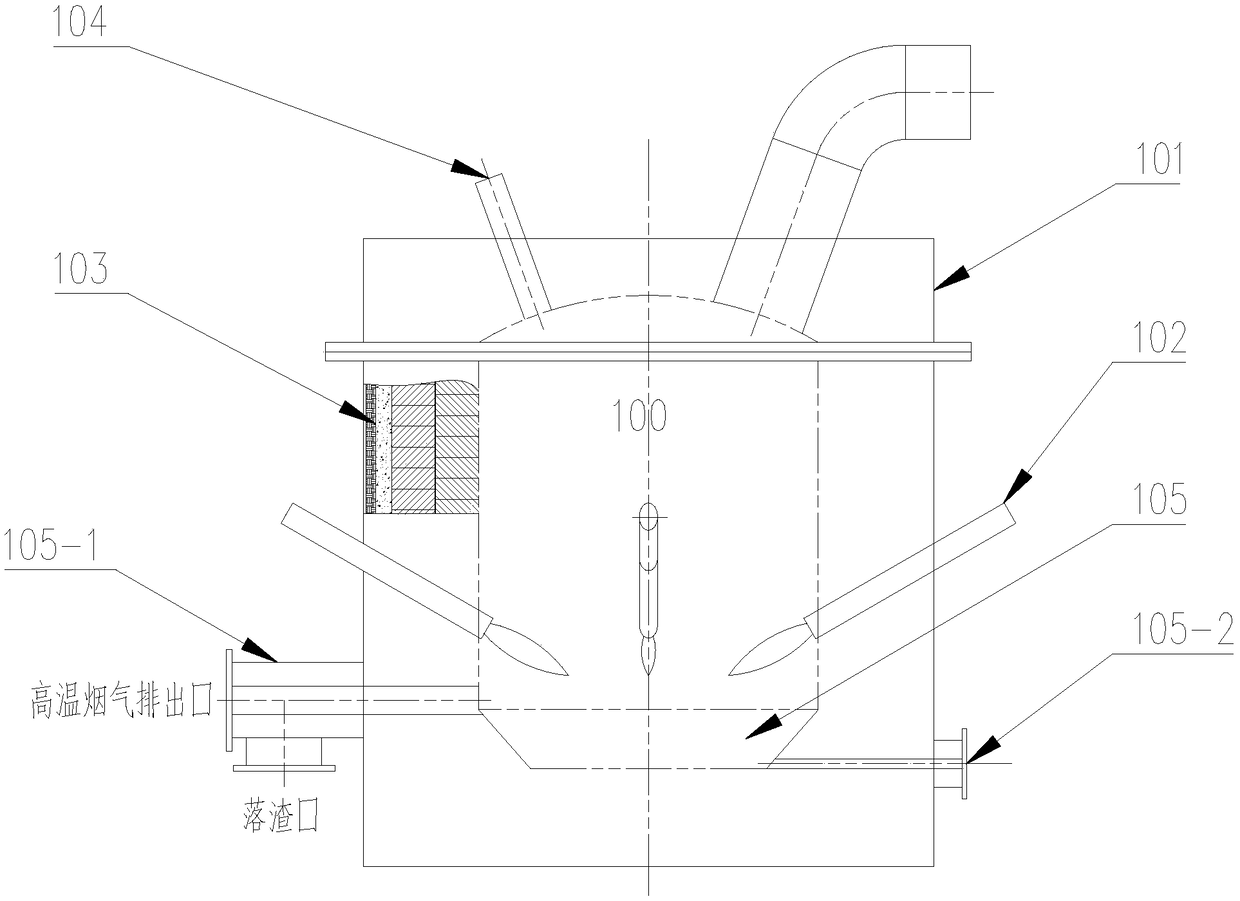

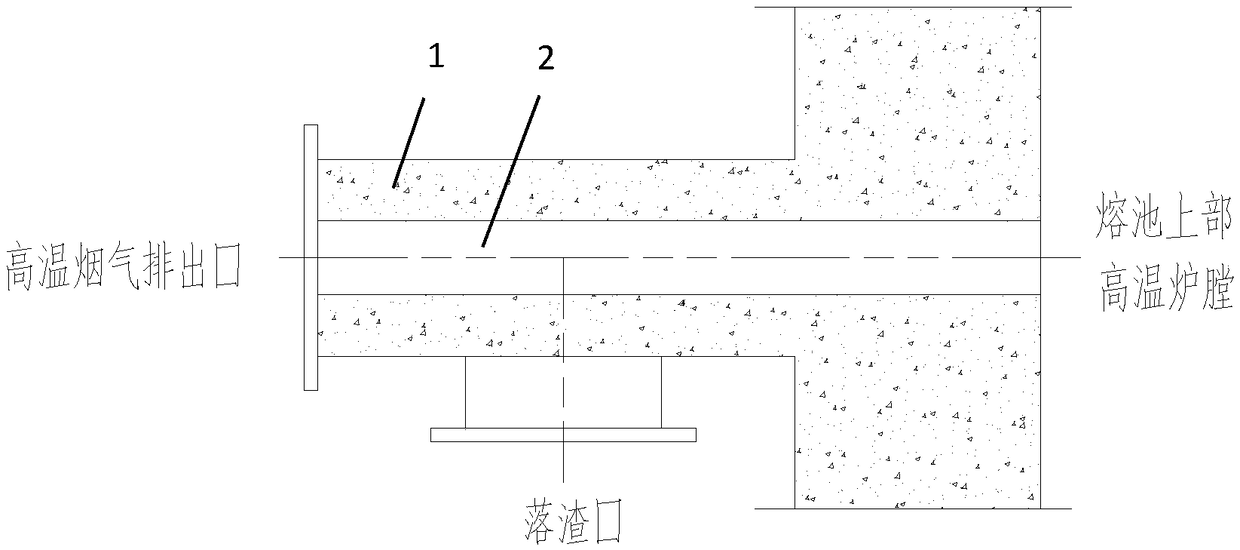

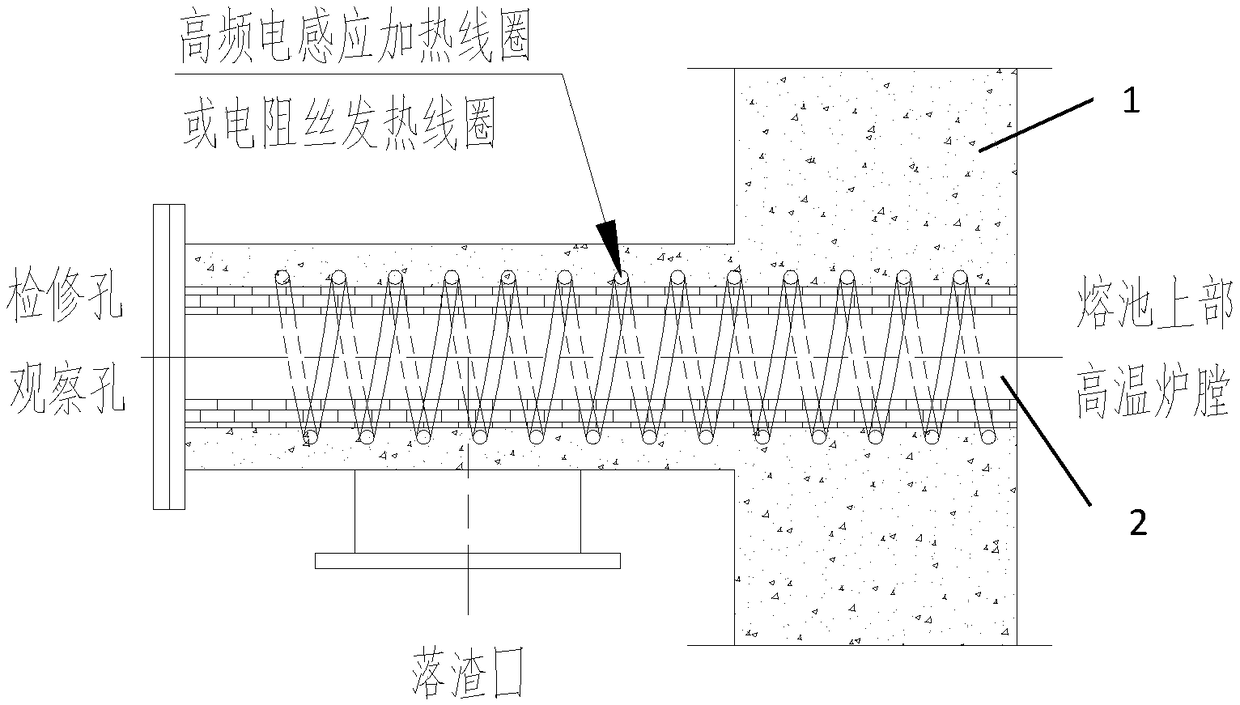

[0038] A continuous overflow slagging plasma melting furnace, such as figure 1 As shown, the melting furnace includes a furnace body 101, a plasma torch heating system and a molten pool, the top of the furnace body is provided with a material inlet, and a furnace hearth 100 is made coaxially in the furnace body, and the material inlet is communicated with the furnace hearth. The molten pool includes a molten pool body 105, a continuous overflow slagging port 105-1 and an intermittent cleaning port 105-2. The furnace body below the furnace is connected with the furnace to make the molten pool body coaxially. The pool bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com