Preparation method of electroluminescent device rare earth nano luminescent layer with conductivity

A technology of electroluminescent devices and conductivity, which is applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of low efficiency, large size and volume, poor stability of electroluminescent devices, etc., to reduce The effect of production cost, simple preparation process and good electron transport ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

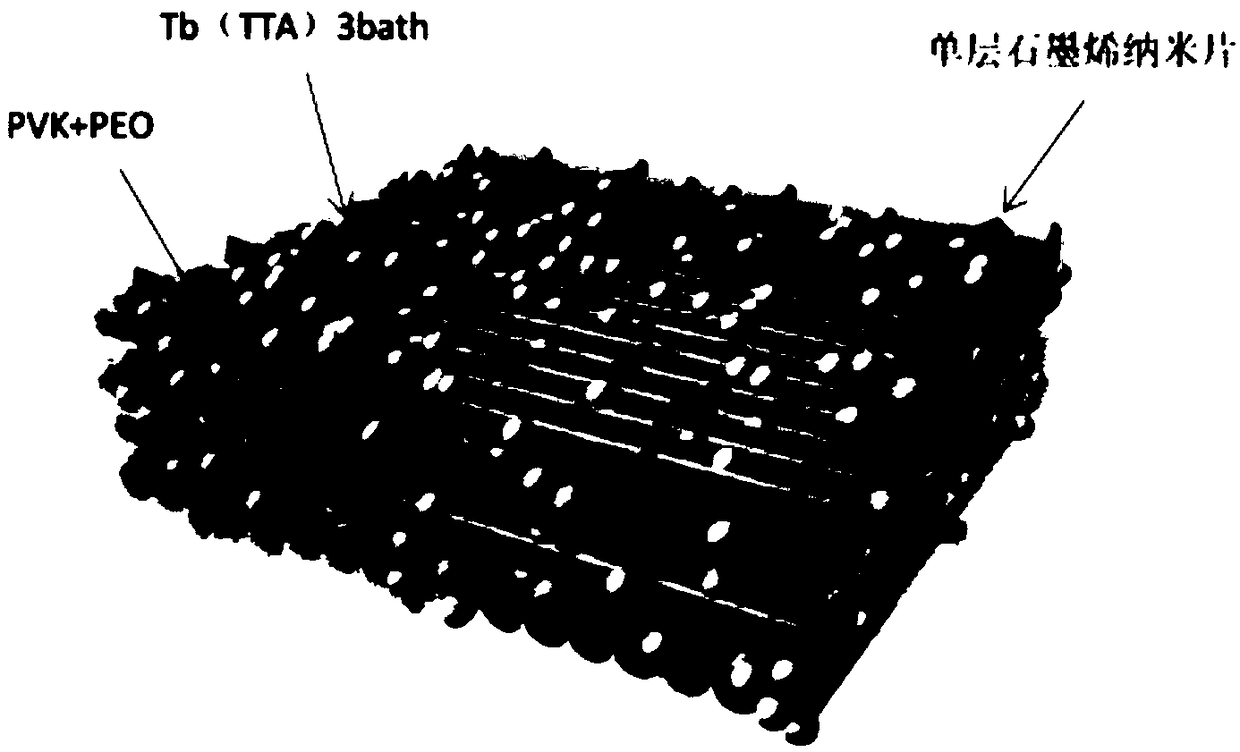

[0026] Such as figure 1 As shown, a preparation method of a rare earth nano-luminescent layer of an electroluminescent device with conductivity is as follows: 5% of the rare earth complex Tb(TTA) 3 bath, 10% PVK and 1% PEO were dissolved in a mixed solvent of chloroform and DMF (CH 3 Cl:DMF, volume ratio 1:1), after stirring for 1 hour, add 3% single-layer graphene nanosheets, and continue stirring for 5 hours to obtain a suspension with uniform viscosity. Fill the spinning solution into the spinneret, use the stable jet electrospinning technology to control the rotation direction of the fiber collecting electrode, and prepare the nanocomposite light-emitting fiber layer of rare earth complexes and conductive substances with multi-level structure and ultra-high orientation structure , and the fiber layer is collected on the FTO substrate to obtain a composite nano-luminescent layer (such as figure 1 shown). During the experiment, the flow rate of the spinning solution was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com