Industrialized making method of ready-to-eat brown rice

A production method and technology of brown rice, applied in the food field, can solve the problems of loss of nutrients, inconvenient eating, rough taste, etc., and achieve the effect of easy absorption, convenient eating, and rich content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

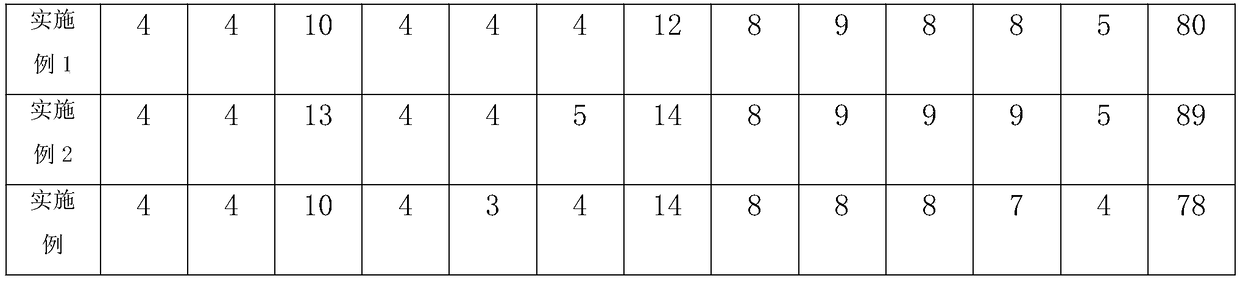

Examples

Embodiment 1

[0033] A kind of industrial production method of instant brown rice, wherein, the preparation method of described instant brown rice is:

[0034] S1. Raw material selection: select and remove impurities from fresh brown rice, and immediately use vacuum low-temperature fresh-keeping treatment on the brown rice that has reached the standard, and immediately carry out fresh-keeping and anti-oxidation treatment after fresh raw materials are sorted out, and cold-chain transportation to make raw materials fresher. The prepared ready-to-eat brown rice has higher quality and better flavor;

[0035] S2, low-temperature grinding: the brown rice kept fresh in vacuum and low temperature is transported to the low-temperature grinding system for grinding into fine particles, the particle size of the fine particles is 200 μm, and the ground brown rice is kept fresh in a stainless steel tank for storage for later use;

[0036] S3. Low-temperature rolling and extrusion granulation: The obtaine...

Embodiment 2

[0043] A kind of industrial production method of instant brown rice, wherein, the preparation method of described instant brown rice is:

[0044] S1. Raw material selection: select and remove impurities from fresh brown rice, and immediately use nitrogen-filled and low-temperature fresh-keeping treatment for the brown rice that meets the standard. After the fresh raw materials are sorted, immediately carry out fresh-keeping and anti-oxidation treatment, and cold-chain transportation makes the raw materials more efficient. Fresh, prepared ready-to-eat brown rice is of higher quality and better flavor;

[0045] S2, low-temperature grinding: the brown rice kept fresh in vacuum and low temperature is transported to the low-temperature grinding system for grinding into fine particles, the particle size of the fine particles is 450 μm, and the ground brown rice is kept fresh in a stainless steel tank for storage for later use;

[0046] S3. Low-temperature rolling and extrusion granu...

Embodiment 3

[0053] A kind of industrial production method of instant brown rice, wherein, the preparation method of described instant brown rice is:

[0054] S1. Raw material selection: select and remove impurities from fresh brown rice, and immediately use nitrogen or carbon-filled low-temperature fresh-keeping treatment for the brown rice that has reached the standard. The raw materials are fresher, and the ready-to-eat brown rice prepared is of higher quality and better flavor;

[0055] S2. Low-temperature grinding: the brown rice kept fresh in vacuum and low temperature is transported to the low-temperature grinding system for grinding into fine particles, the particle size of the fine particles is 680 μm, and the ground brown rice is kept fresh in a stainless steel tank for storage for later use;

[0056] S3. Low-temperature rolling and extrusion granulation: The obtained powder is transported to the rotary granulator at a quantitative and uniform speed. It forms particles through s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com